Maintenance

- 73 -

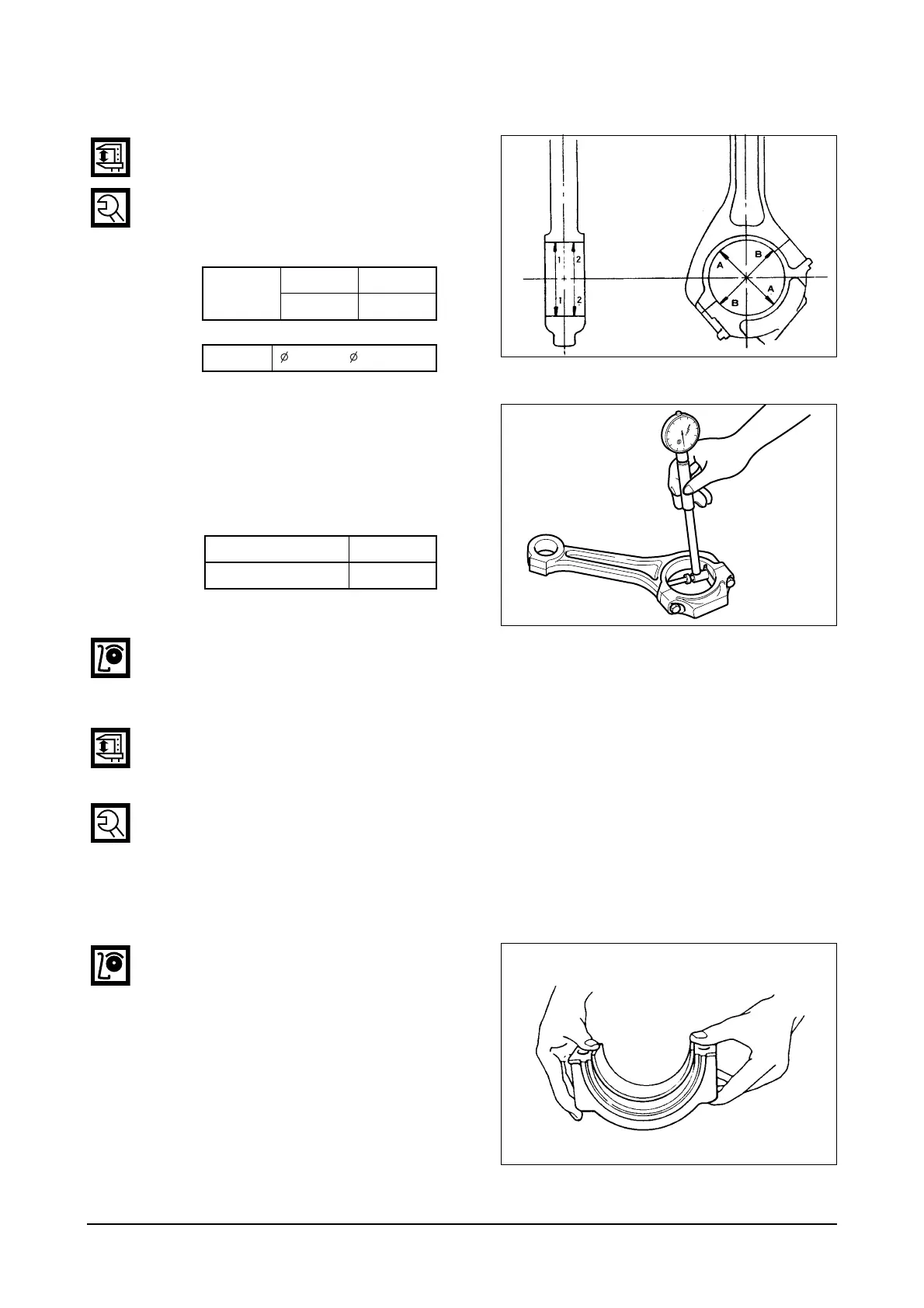

c) Connecting rod bearing clearance

Install the connecting rod bearing

in the connecting rod bearing cap,

tighten the connecting rod cap

bolts to the specified torque, then

measure the inside diameter.

Compare the two values obtained

through measurement of connecting

rod bearing inside diameter with the

outside diameters of crankshaft pins

to determine the oil clearance.

If the clearance deviates from the specified range, have the crankshaft journals and pins

ground and install undersize bearings.

d) Oil clearance between crankshaft and bearing (Method 2 : plastic gauge)

Assemble the crankshaft on the cylinder block and put plastic gauge on the journal and pin of

crankshaft and then after assembling bearing cap, tighten the bolts at the specific torque.

Again after disassembling the bearing cap by removing the bolts, take out the flatted plastic

gauge and measure the width of plastic gauge by means of plastic gauge measuring scale.

This is the oil clearance.

The oil clearance too can be easured in the same manner.

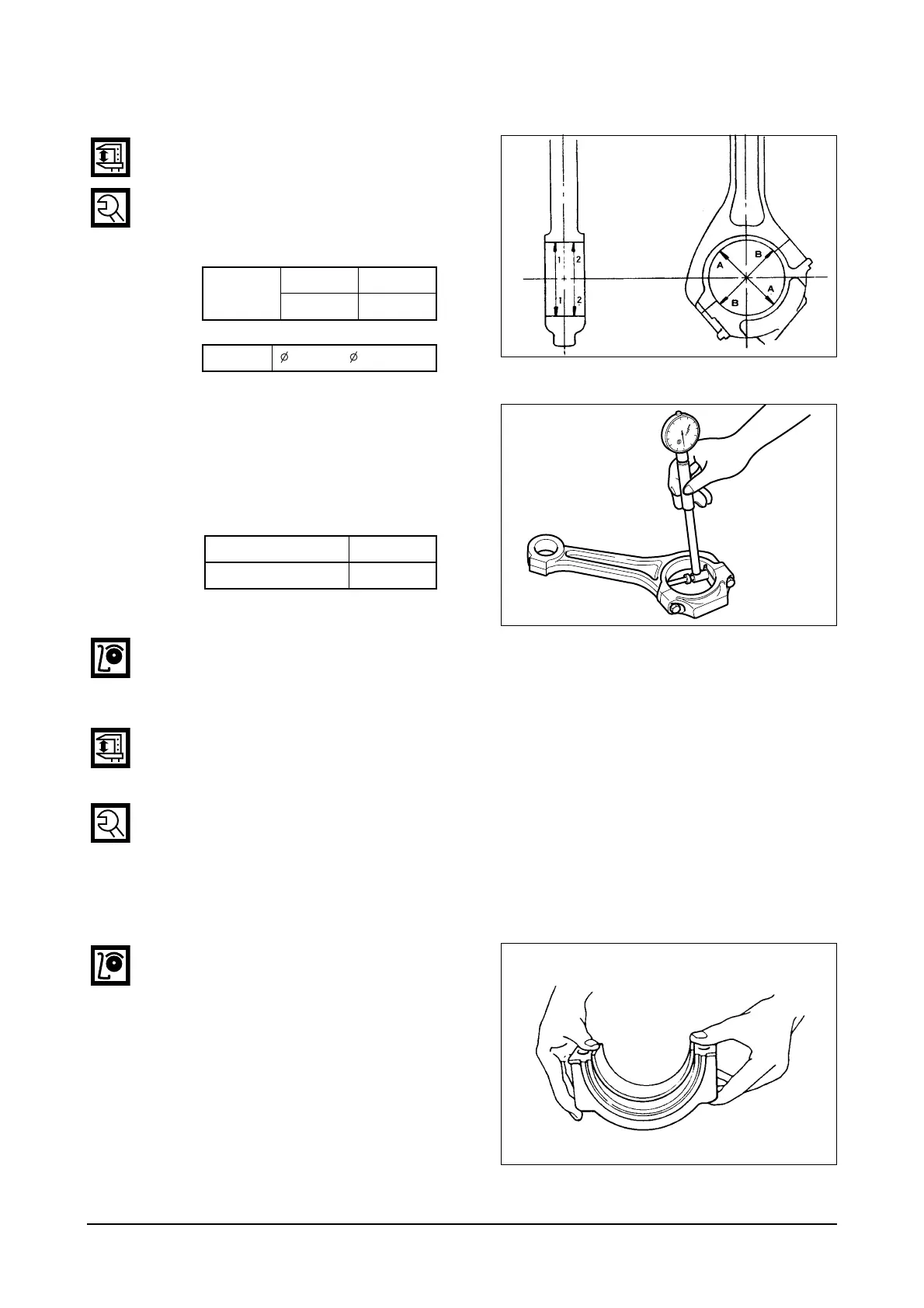

e) Bearing spread and crush

Inspection

Check to see that the bearing

requires a considerable amount of

finger pressure at reassembly

operation.

Torque

1st Step 4 kg

•

m

2nd Step 60°

Standard 76.000

~

76.019

mm

Standard Limit

0.034

~

0.098

mm 0.25 mm

Loading...

Loading...