(2) Clearance

Measure the clearance between the piston

pin and connecting rod bushing, and

replace either of them, whichever dam-

aged more, if the measured value is

beyond the limit.

(3) Condition check

Check the engaged condition of the piston and piston pin. If it is possible to force the pin into

the piston heated with piston heater, the piston is normal. When replacing the piston, be sure

to replace the piston pin together.

5) Connecting rod inspection

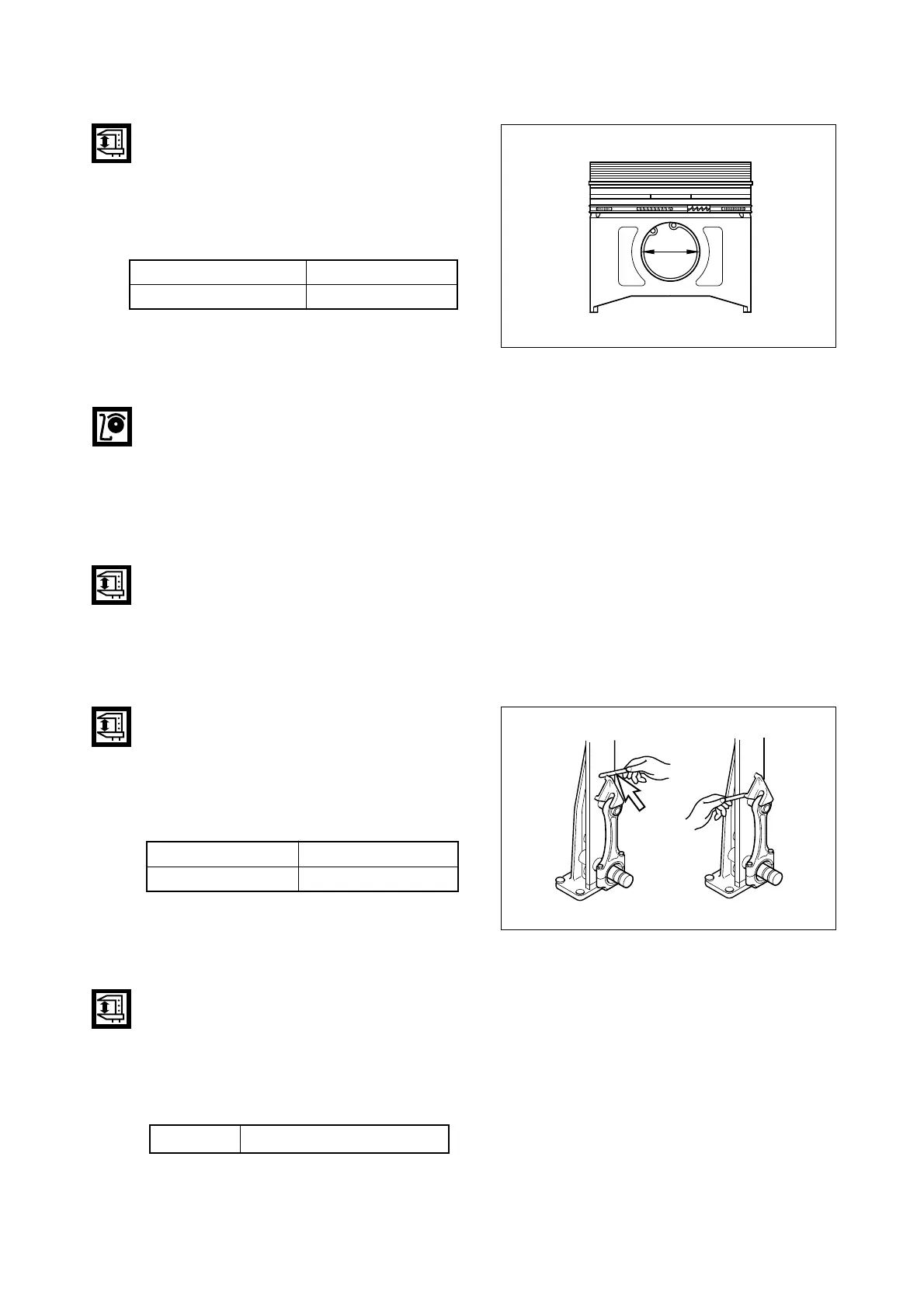

(1) Distorsion

Check the connecting rod for distortion. As shown in the figure below, install the connecting

rod to the connecting rod tester, and check for distortion using a feeler gauge. If the con-

necting rod is found distorted, never re-use it but replace with a new one.

(2) Holes alignment (parallelism)

Measure the alignment of the connecting

rod piston pin bushing holes with

connecting rod big end holes. At this time

also, use both connecting rod tester and

feeler gauge.

(3) Wear

•

Assemble the connecting rod to the crankshaft and measure connecting rod big end side

clearance using a feeler gauge.

•

Assemble the connecting rod to the piston and measure connecting rod small end side

clearance.

•

If the measured values are beyond the limit, replace the connecting rod.

- 96 -

Loading...

Loading...