•

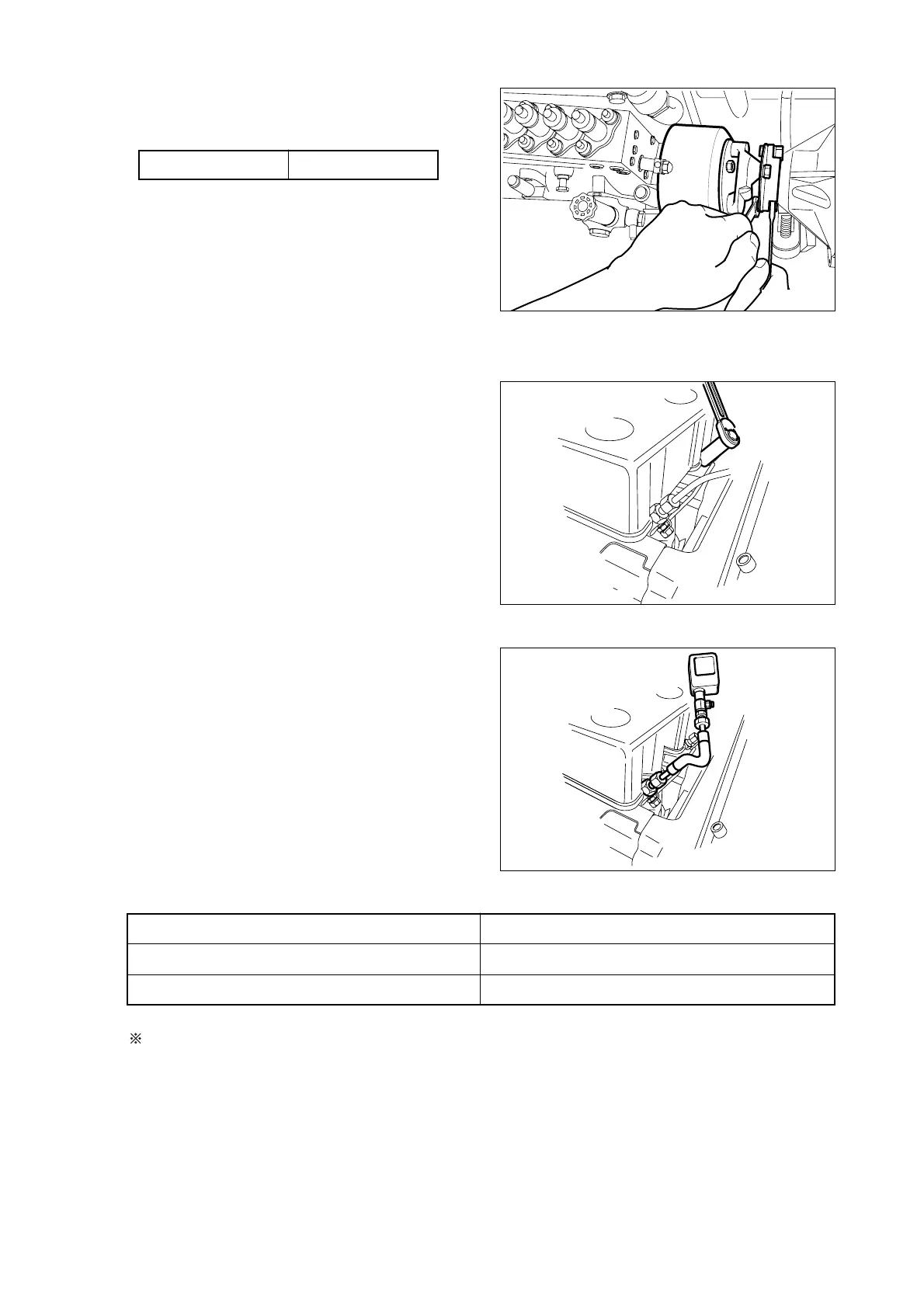

Tighten the coupling fixing bolts and nuts

to specified torque.

6.3. Cylinder Compression Pressure

1) Stop the engine after warming it up, then

remove the nozzle assemblies.

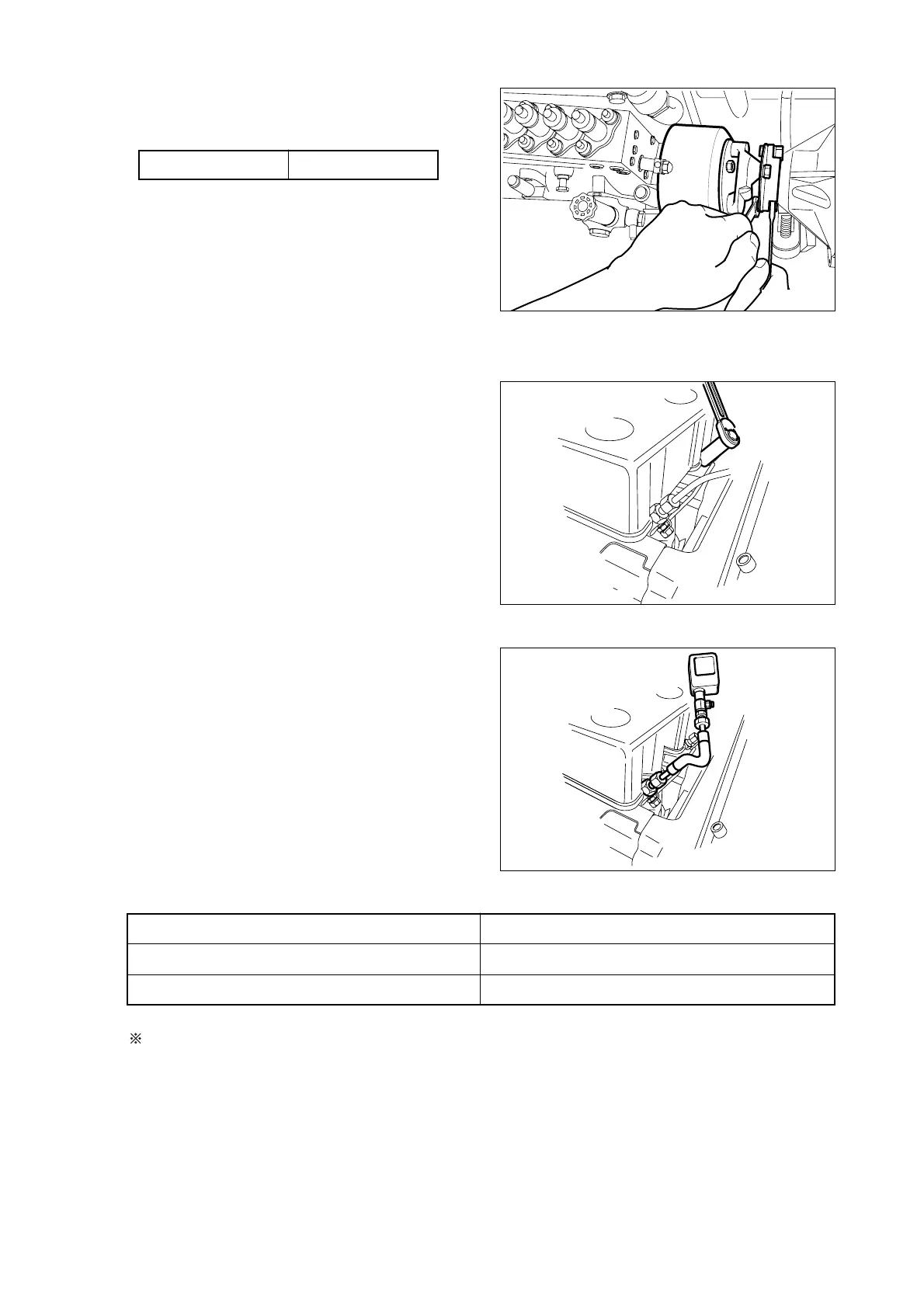

2) Install a special tool (gauge adapter) in

nozzle holder hole and connect the com-

pression pressure gauge to the adapter.

3) Cut off fuel circulation, rotate the starter,

then measure compression pressure of

each cylinder.

Testing conditions : at water temperature of 20

˚

C and speed of 200 rpm (10 turns)

- 49 -

Loading...

Loading...