5.4.3. Cleaning filter elements

•

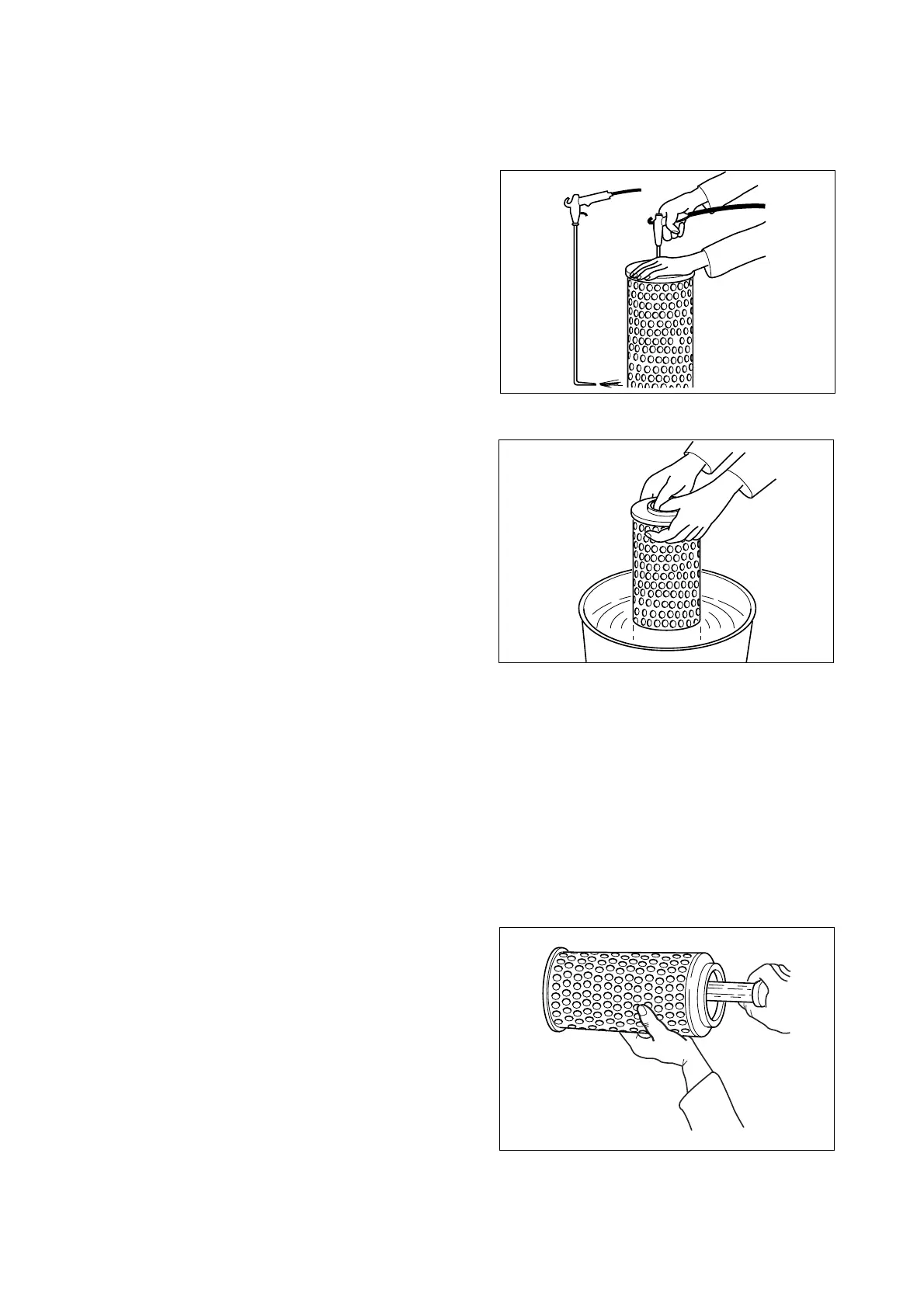

By compressed air

(wear goggles)

For the purpose, the air gun should be fit-

ted with a nozzle extension which is bent

90? at the discharge end and which is

long enough to reach down inside to the

bottom of the element.

Moving the air gun up and down, blow

out the element from the inside (maxi-

mum 500kPa - 5 bar) until no more dust

comes out of the filter pleats.

•

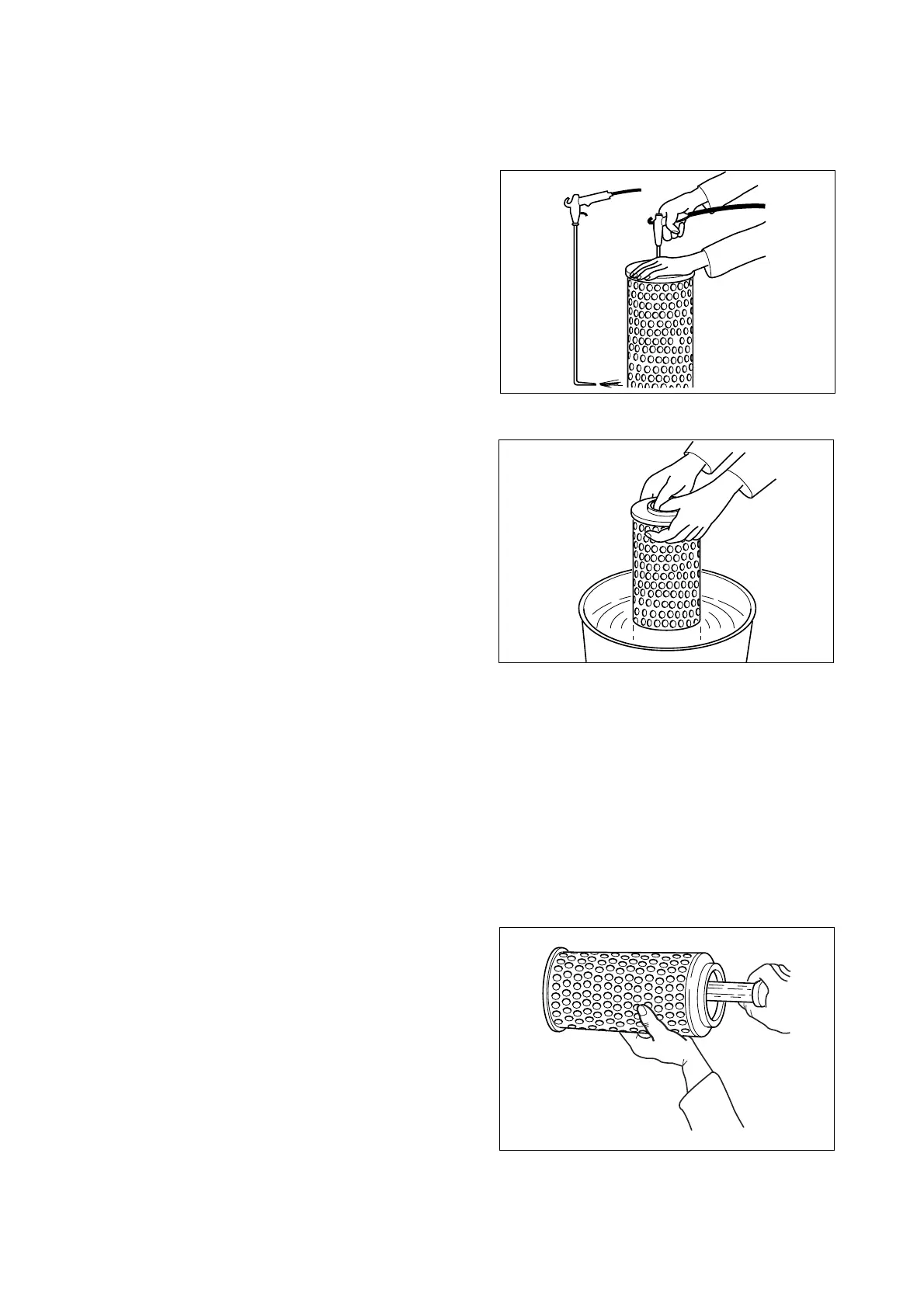

By washing

Before washing, the element should be

precleaned by means of compressed air,

as described above.

Th

en allow the element to soak inlukewarm

washing solvent fo

r10 minutes, and then

move it to and for in the solvent for about

5 minutes.

Rinse thoroughly in clean water, shake

o

ut and allow drying at r

oom temperature.

The cartridge must be dry before it is

reinstalled. Never use steam sprayers,

petrol (gasoline), alkalis or hot liquids etc.

to clean the filter elements.

•

Knocking out dirt by hand

In emergencies, when no compressed air or cleaning agent is available, it is possible to clean

the filter cartridge provisionally by hitting the end disk of the cartridge with the ball of one’s

thumb.

Under no circumstances should the element be hit with a hard object or knocked against a hard

surface to loosen dirt deposits.

•

Checking the filter cartridge

Before reinstalling the cartridge, it must

be checked for damage e.g. to the paper

pleats and rubber gaskets, or for bulges

and dents etc. in the metal jacket.

Cracks and holes in the paper pleating

can be established by inspecting the car-

tridge with a flashlight.

Damaged cartridges should not be

reused under any circumstances. In

cases of doubt, discard the cartridge and

install a new one.

- 39 -

Loading...

Loading...