- 43 -

5.6. Injection Nozzle Maintenance

(by authorized specialist personnel)

The injectors are designed to spray the

fuel delivered by the injection pump direct-

ly into the spherical combustion chamber

in the piston crown.

The injector consists of the nozzle and the

nozzle holder.

A copper seal fitted to the injector ensures

gas-t

ight seating and good he

at dissipation.

The opening pressure of the nozzle is

adjusted by means of shims at the com-

pression spring.

•

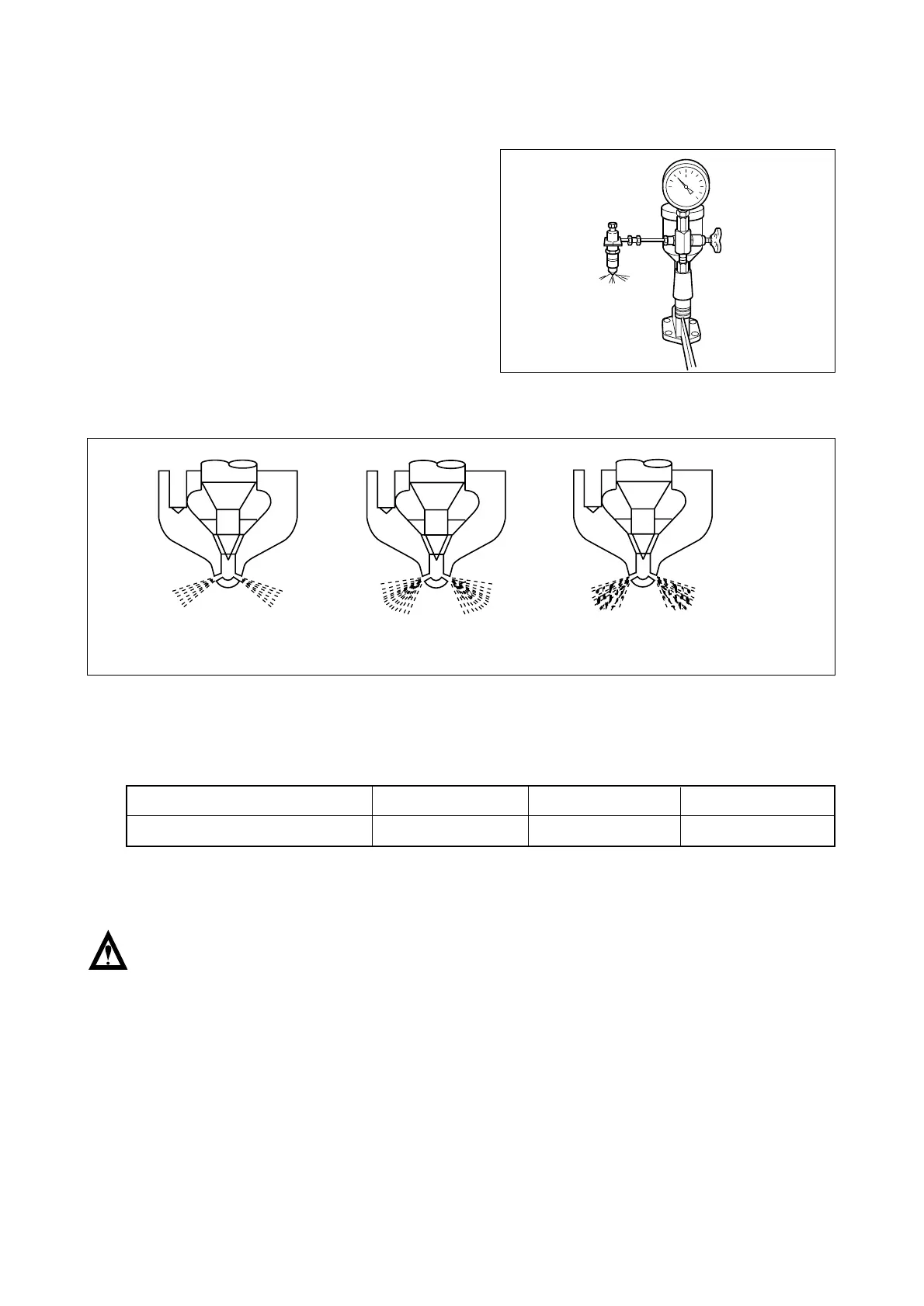

Install a nozzle to a nozzle tester.

•

Check injection pressure, and adjust the nozzle using the adjusting shim if the pressure does not

meet the specified limit.

•

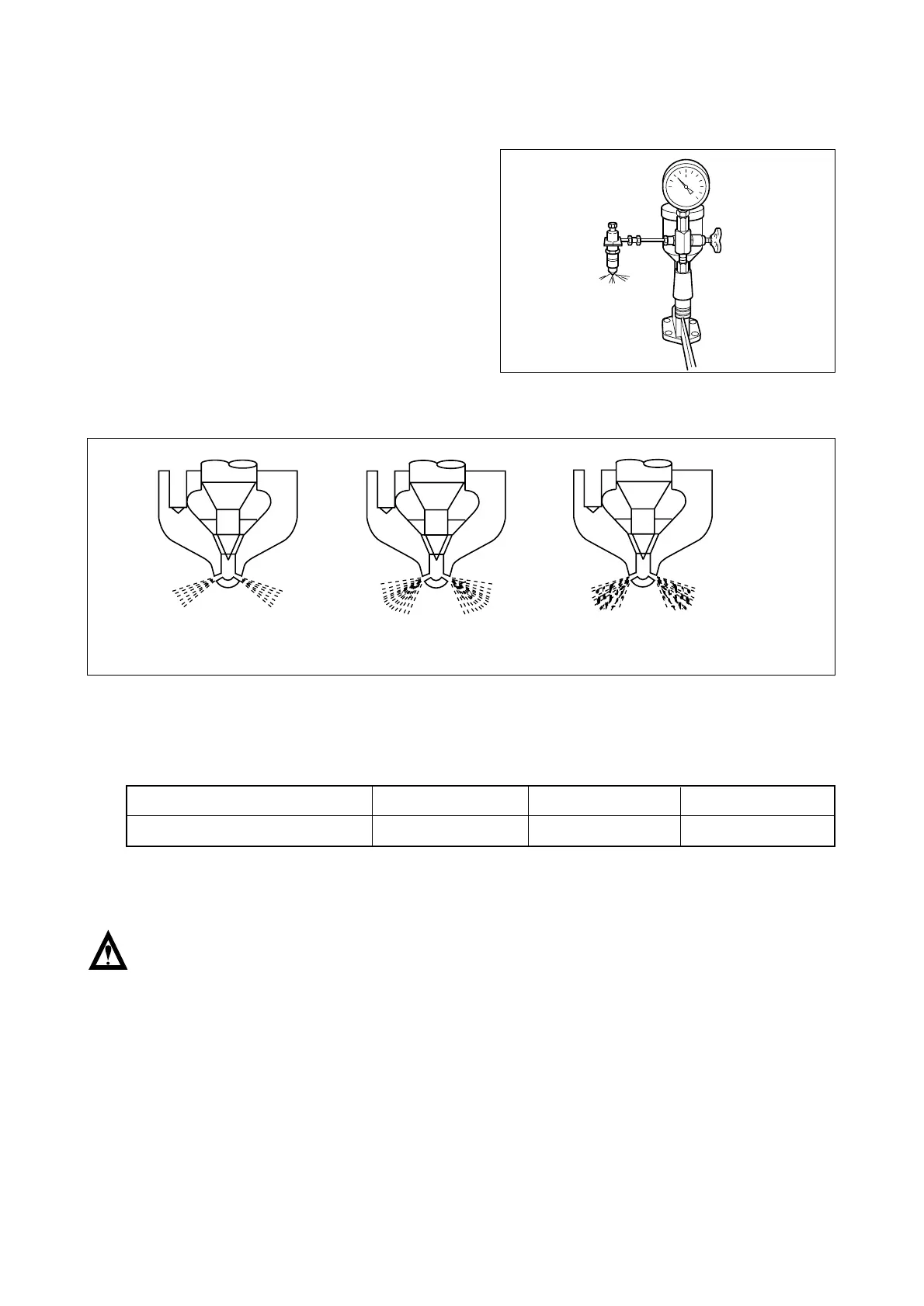

Check nozzle spray patterns and replace if damaged.

CAUTION :

The injection lines are designed for high operating pressures and should thus be handled with

particular care.

•

When mounting the pipes to the engine take care of good fitness.

•

Do not bend pipes to permanent deformation (not for replacing the nozzles either).

•

Do not mount any heavily bent pipes.

•

Avoid bending the pipes at the ends by more than 2 to 3 degrees.

In case of faults in the injection system which might have resulted in excessive operating pres-

sures, not only the failed part but also the injection line has to be replaced.

Loading...

Loading...