1110

AUTOMATIC DETECTOR DORS 200 AUTOMATIC DETECTOR DORS 200

CONTENTS

PERIODIC MAINTENANCE

The maintenance requires a partial disassembling of the detector by a technician.

We recommend delivering the said maintenance every 90 days. In case of intensive

use of detector (more than 1 shift a day), the maintenance should be performed more

frequently.

On a daily basis:

1. Switch off the detector if it is not used.

2. Wipe the external parts with a dry clean lint-free cloth.

On a weekly basis or once three days at an intensive use:

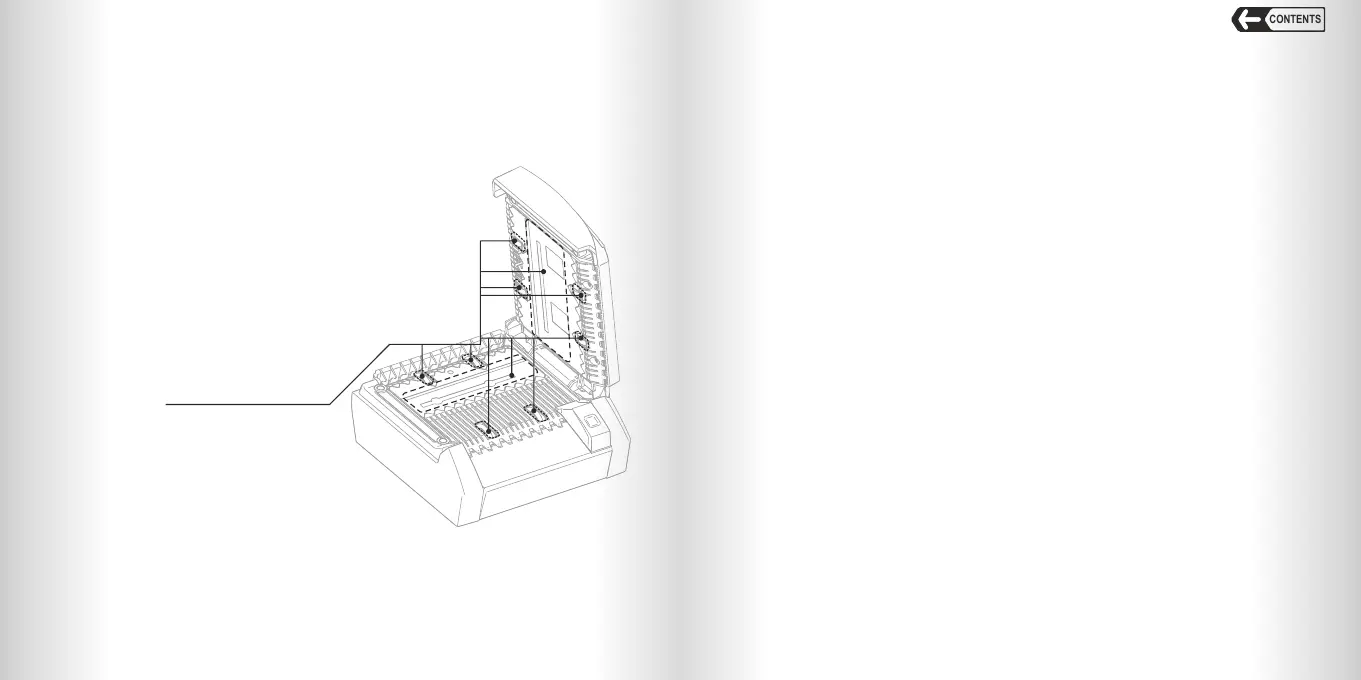

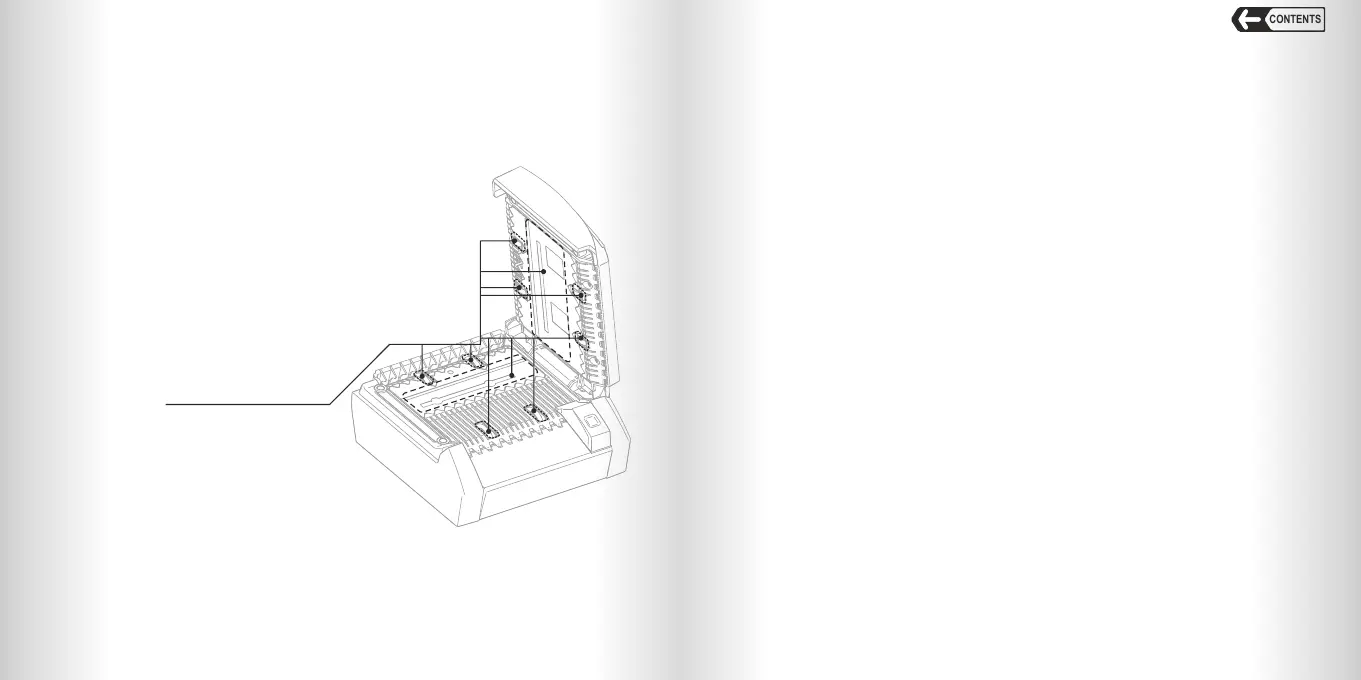

1. Open the detector top cover and wipe with a dry clean lint free

cloth the path, the light guide, the scanner and the other

parts shown in Fig. 5

2. Switch the detector on and press «ON/OFF» key

(the top cover is still open). The feeding rollers will start

rotating forward for several seconds. While the feeding

rollers are rotating wipe them with a cotton pad

moistened with alcohol-containing cleaner.

Repeat cleaning if required.

Fig. 5

The areas indicated by the dotted

line require periodic cleaning

TRANSPORTATION

AND STORAGE

The detector may be transported in the

manufacturer's package by car or by railway

(in a covered transport vehicle), by air in the pressurized

modules at the temperature of –20°…+50°C, relative air humidity up to 98% at +25°C

and the atmospheric pressure 84 to 107 kPa (630 to 800 mmHg).

Store the detector in the manufacturer's package in a heated and ventilated

storage room at +5°…+40°C and relative humidity not exceeding 80% at +25°C.

WARRANTY AND SUPPORT

DORS authorizes the local distributors to provide after-sales technical support to

the customers. In case of machine's malfunctioning please contact your local supplier.

If you fail to get support from your supplier, please inform us at web site

http://dors.com/oe/. To avoid any misunderstanding we ask you to read the

description of the machine's operation, its transportation and storage, the warranty

conditions.

Loading...

Loading...