MACHINE FOR BINDING BANKNOTES AND SECURITIES (BANDING MACHINE) DORS 500

15

POSSIBLE MESSAGES APPEARING

IN THE COURSE OF OPERATION

1. Display indicates: blinks in the

"HAND" or "AUTO" mode.

Meaning: the tape left in the roll is on

ly enough for 1520 bindings.

Actions: prepare a new roll for replace

ment when the current one is used up.

THE DEVICE NEEDS MAINTENANCE

IF "SRC" FLASHES FOR 4 SECONDS

ON THE INDICATOR

AFTER SWITCHING THE DEVICE ON.

2. Display indicates: "nL X" (where X

is the configuration setting num

ber).

Meaning: no loop.

Actions: Create a loop (see page

22, Section 6).

3. Display indicates: "PE"

Fault: paper feed path error.

Actions: charge the tape again (see

section "Operation Procedure").

4. Display indicates: "____".

Fault: device cover 13 (fig.1) is

opened.

Actions: close the cover.

POSSIBLE ERRORS

OF AUTO TEST PROCEDURE

(AT THE DEVICE SWITCHING ON

AND OPERATION)

1. Display indicates: after the device

switching on, there is no indication

on the display.

Actions: test the power cord.

Switch on again. If there are no

changes, contact the service cen

ter.

2. Display indicates: "uPF".

Fault: the front cover is open.

Actions: close the front cover. If

there are no changes, contact the

service center.

3. Display indicates: "SF".

Fault: proximity sensors are dirty or

covered by a foreign object.

Actions: clean the proximity sen

sors, remove the foreign object

from the device table. If there are

no changes, contact the service

center.

4. Display indicates: "utF".

Fault: the tape drive unit is faulty.

Actions: contact the service center.

5. Display indicates: "HuF".

Fault: heater drive unit is faulty.

Actions: contact the service center.

6. Display indicates: "CuF".

Fault: the rotary grip drive unit is

faulty.

Actions: contact the service center.

7. Display indicates: "nP".

Fault: there is no tape in the device

path.

Actions: set the tape roll and char

ge the tape in the path according

to section "Operation Procedure".

PRIOR TO SENDING UNIT

FOR SERVICING, POWER OFF

THE UNIT, REMOVE THE LOOP

(IF ANY) AND REMOVE THE ROLL.

ERROR CODES AND DIAGNOSTIC MESSAGES

MACHINE FOR BINDING BANKNOTES AND SECURITIES (BANDING MACHINE) DORS 500

14

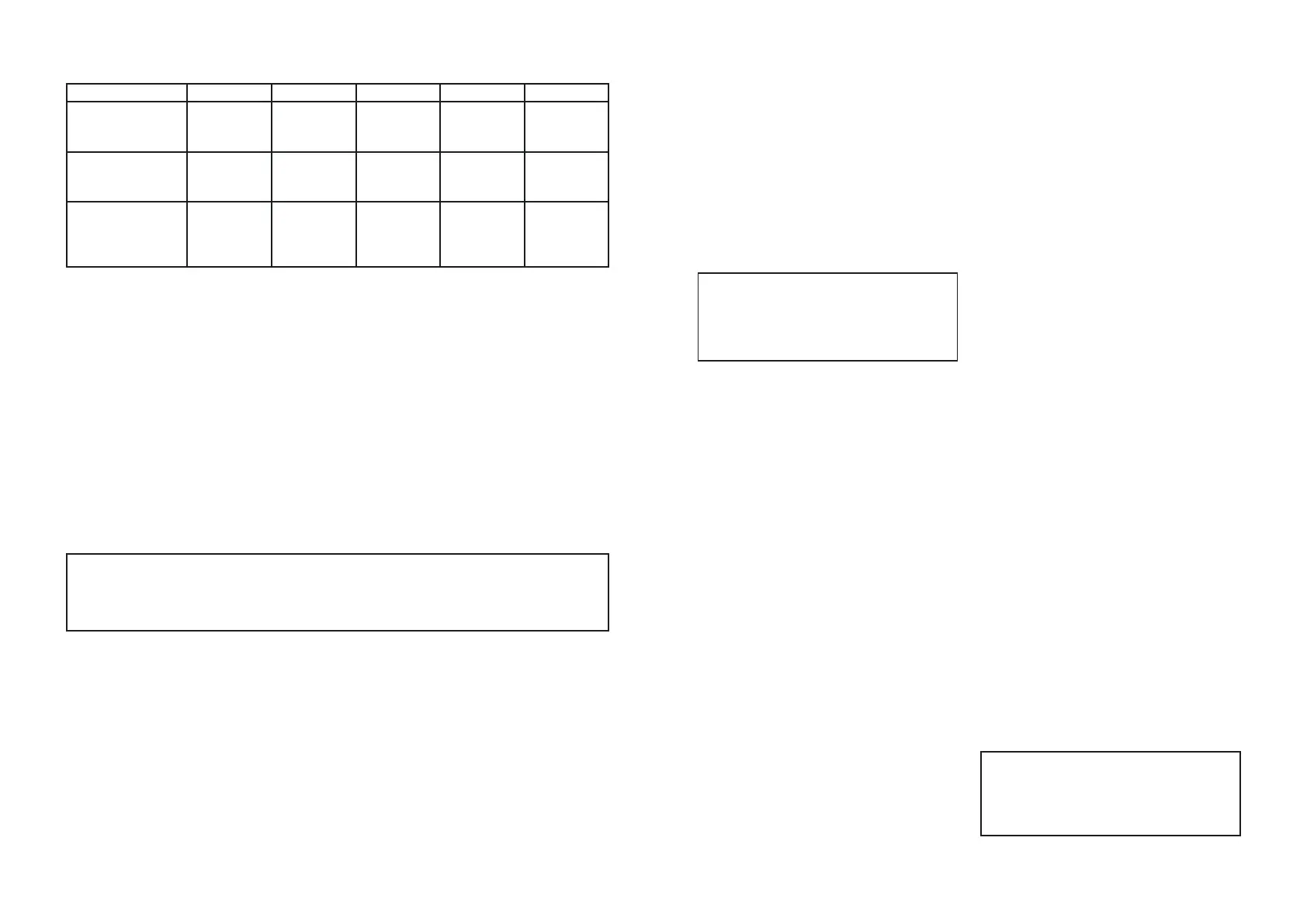

Table 3. Functions of the buttons

UP SELECT DOWN AUTO START

HAND

Next

configuration

setting number

Switching

to the "SET"

mode

Previous

configuration

setting number

Switching

to the

"AUTO" mode

Start

of wrapping

AUTO

Next

configuration

setting number

Switching

to the "SET"

mode

Previous

configuration

setting number

Switching

to the

"HAND" mode

SET

Increase

in the

parameter

value

Selection

of the next

parameter

Decrease

in the

parameter

value

Exit from the

"SET" mode to

the "AUTO"/

"HAND"

may cause tape coated layer scra

ping. Loosen the tension to elimi

nate this effect.

2. The "t" and "r" parameter values

shall be selected with considera

tion for the following:

z the heating time (t) shall provide

for the quality glue stripe whilst

avoiding the paper turning yel

low in the glue stripe area.

A proper heating shall cause the

glue layer to "melt" in the gluing

area on both sides of the tape;

z the cooling time (r) shall provi

de for an acceptable binding

cycle whilst allowing the glue

layer to cool down completely.

A lack of gluing through the

end of a binding cycle may

cause the seam to part whilst

making visible the glue layer

shift marks on the tape surface.

The configuration settings stored through the previous shutdown

shall be enabled at the unit startup.

The unit, however, will start in the "HAND" mode

as a consideration of safety performance.

Loading...

Loading...