Plus and PSS Series - Lung Demand Valve

tm 1285.001 - August 2001

5:13

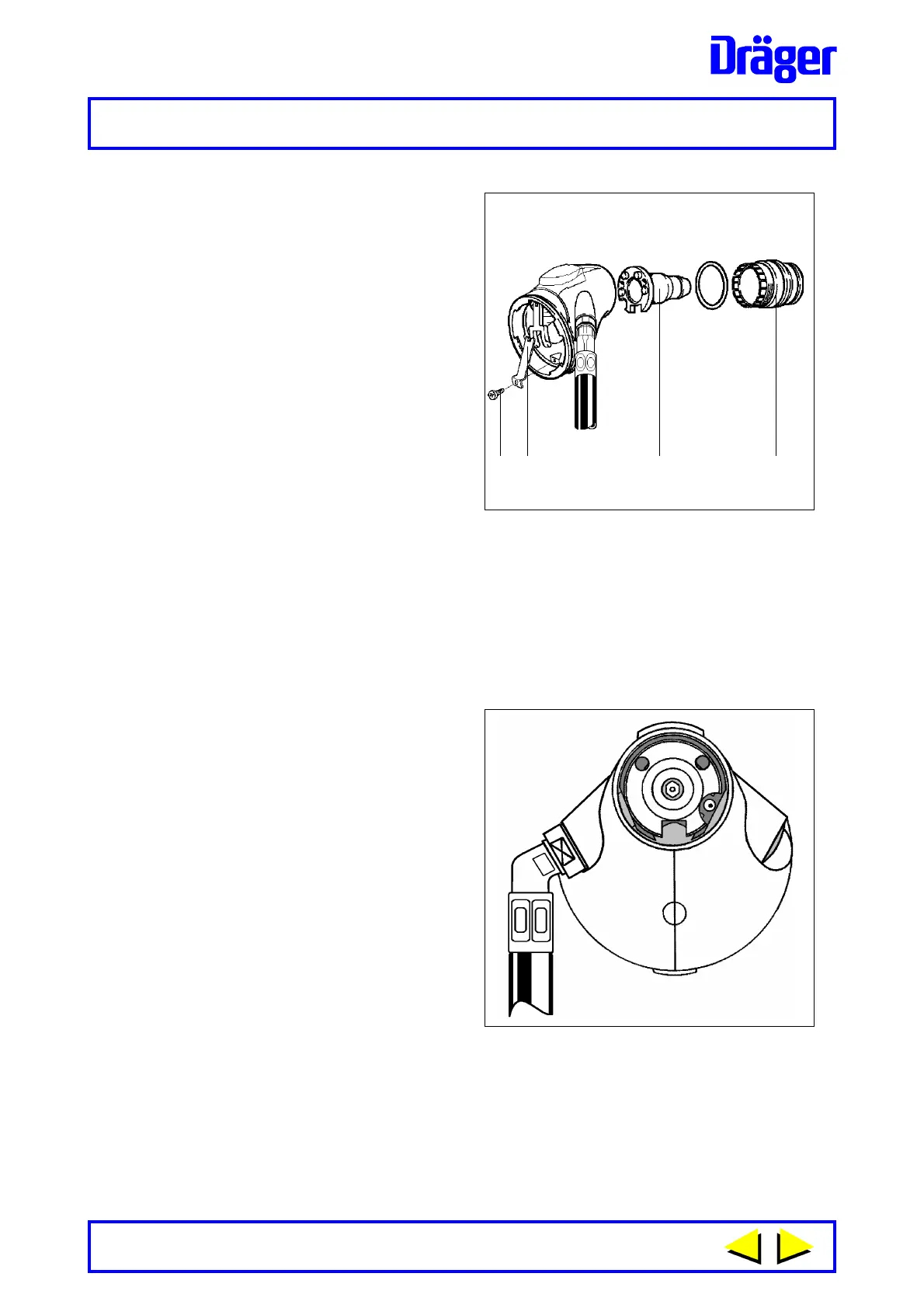

Refer to Fig. 11.

4 Using posi-driv screwdriver

unscrew retaining screw (1) until

the locking arm (2) is able to be

withdrawn from castellation of

connector (3).

5 Remove connector as follows.

Note: Do Not

attempt to remove push-

in or screw-in type connectors

with locking arm located in the

castellation of connector. Refer

to instruction 4.

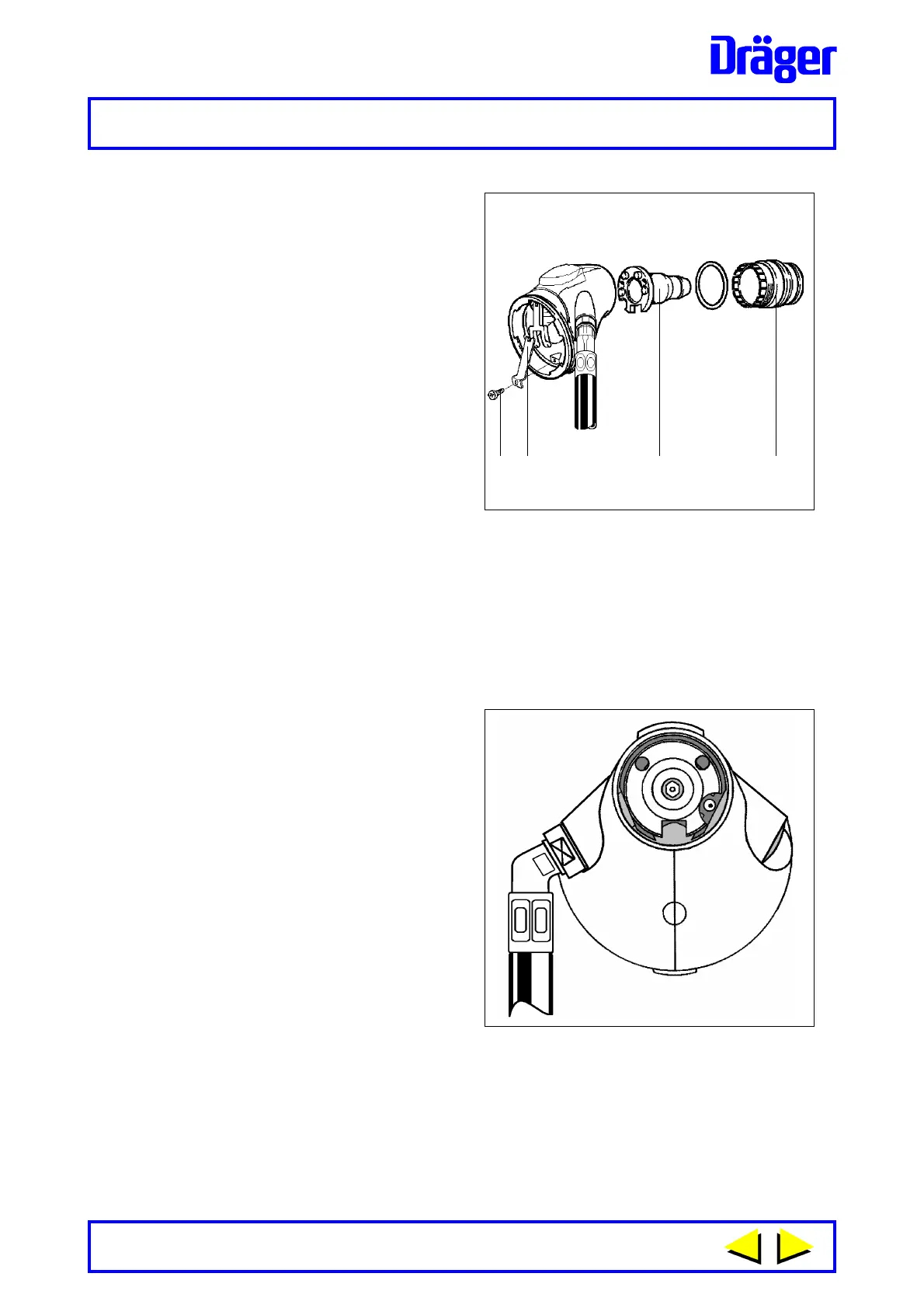

Fig. 12

1139

2

Fig.11

1

1138

3

Push-in Type - A

Grip and unscrew push-in type connector (anti-clockwise) from demand

valve body. Remove injector pipe (4).

Screw-in Type - AE and N

Using connector tool (3310679) - insert pins of tool into swivel connector -

rotate to align slots of fixed end of connector and fully insert pins - unscrew

(anti-clockwise) to remove screw type connector and handwheel assembly

from demand valve body. Remove injector pipe (4).

6 Locate and correctly position

the new injector pipe as shown

in Fig. 12.

Important Note: Fit only the correct Injector

Pipe to the appropriate lung

demand valve.

7 Hold body of lung demand

valve with the injector pipe in

the vertical position then

assemble connector as follows.

Push-in Type - A

Inspect and if necessary fit new

O-ring to connector then screw

connector into demand valve

body. Tighten until flange of the

connector contacts the body of

the demand valve. Do Not

overtighten.

4

Loading...

Loading...