07-01839A F413-115V 2013-11 Warranty 07-00420 5 Dri-Eaz Products, Inc.

The following tools and supplies are needed to

complete the maintenance procedures described in

this manual:

Philips screwdriver

10 mm wrench

6 mm hex bit

¼ in. nut driver

Cleaning cloths

HEPA vacuum cleaner with soft brush nozzle and

crevice nozzle.

Recommended

Cordless drill, small knife, small-jaw pliers, coil clean-

ing solution, rotomolded housing cleaning solution.

Before each use

Inspect the electrical cord for damage. Look for fray-

ing, cuts, etc. Replace the cord if you find any damage.

Inspect, vacuum or replace filter. The Revolution is

provided with a 3M™ HAF High Air Flow filter (part no.

F372). HAF filters may be vacuumed clean and re-

used up to three times before replacement. Use a

HEPA vacuum and brush tool to remove any dust or de-

bris. Do not use compressed air or expose the filter to

any liquids, as may damage the filter.

Monthly

Inspect coils. Clean when dust accumulation is visible.

In normal use, dust can accumulate and can restrict air-

flow, reducing performance and causing the unit to over-

heat. Use a vacuum cleaner with a brush tool and a soft

cloth to remove any debris. Take care not to damage

any interior components.

To maintain appearance, wipe interior and exterior sur-

faces with a damp cloth. For deep cleaning and a last-

ing, protective shine, use an automotive interior cleaner.

As Needed

Clean pump check valve and basin. If the unit displays

the message “ER9 PUMP BLOCKED CHECK PUMP &

HOSE”, the pump check valve and pump basin may

need to be cleaned. Remove grills and cover as shown

in Fig. B. Remove screws from pump base and lift out

pump. Wipe out pump basin with a damp cloth. Inspect

the pump base for build-up of debris and clean if need-

ed. Unthread barbed fitting with check valve and rinse

fitting and check valve with clean water. Reinstall check

valve into barbed fitting and install the barbed fitting into

pump. Do not overtighten. Reinstall pump on base. Re-

install cover and grills.

Clean coils. Inspect the horizontal evaporator (cold) coil

with the cover removed. If excessive dust and debris is

present, vacuum thoroughly and/or clean with coil clean-

er.

ABOUT 3M™ HIGH AIR FLOW FILTERS

HAF filters from 3M provide superior particle retention, resist microbial growth on filter surfaces and allow for maximum

airflow throughout the filter loading cycle. Follow these guidelines to ensure maximum protection for equipment, techni-

cians and the job site:

Replace the HAF filter whenever it has been vacuumed clean and reused three times. HAF filters lose their effectiveness after

three uses.

Replace the HAF filter whenever it has been used on a mold remediation job or otherwise exposed to potentially dangerous

contaminants. Continued use of a contaminated filter risks the spread of contamination.

Do not wash or apply any liquids to the HAF filter. Exposure to liquids will reduce the effectiveness of the electrostatic material.

Do not operate without the HAF filter in place. Do not operate the unit with any other filter type. Incorrect filtration will reduce

unit efficiency and can cause damage to the unit.

Use the optional mesh filter when excessive dust or airborne particles are present. High volumes of particulates present during

sanding, spray painting, or similar operations can clog the unit and cause damage.

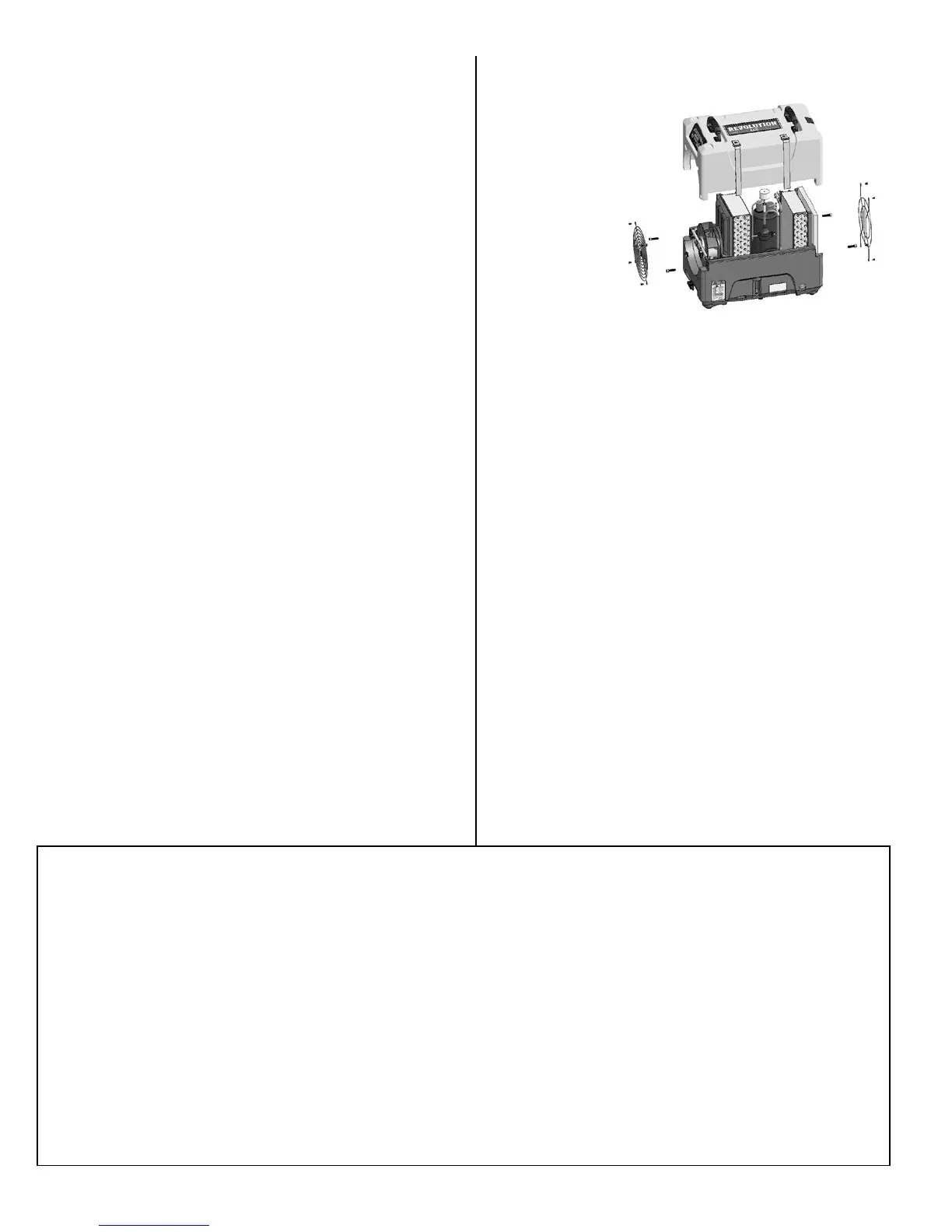

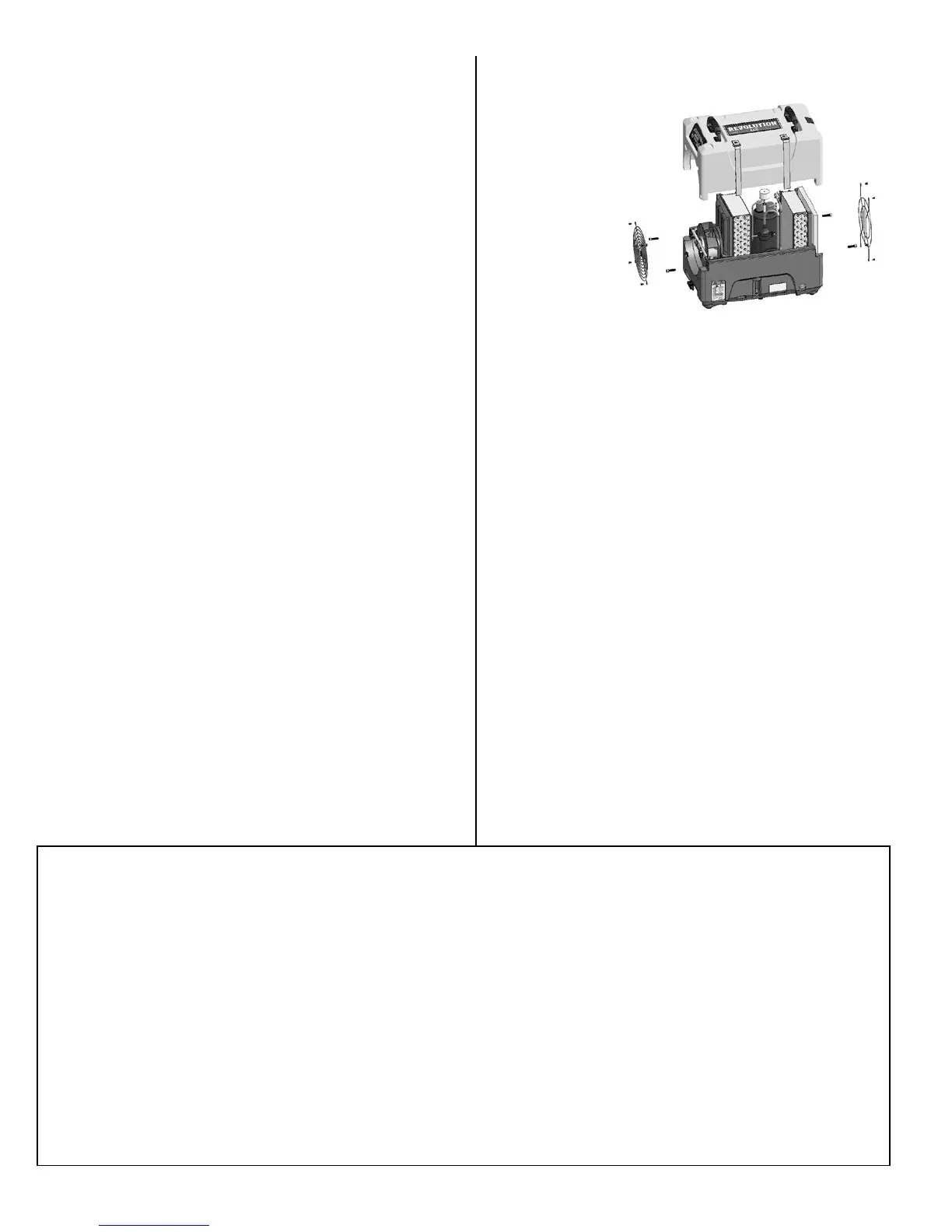

from housing and 2

top screws each from

inlet and outlet grills

and lift off cover.

Fig. B: Disassembly for Cleaning

Loading...

Loading...