16

www.drilldoctor.com

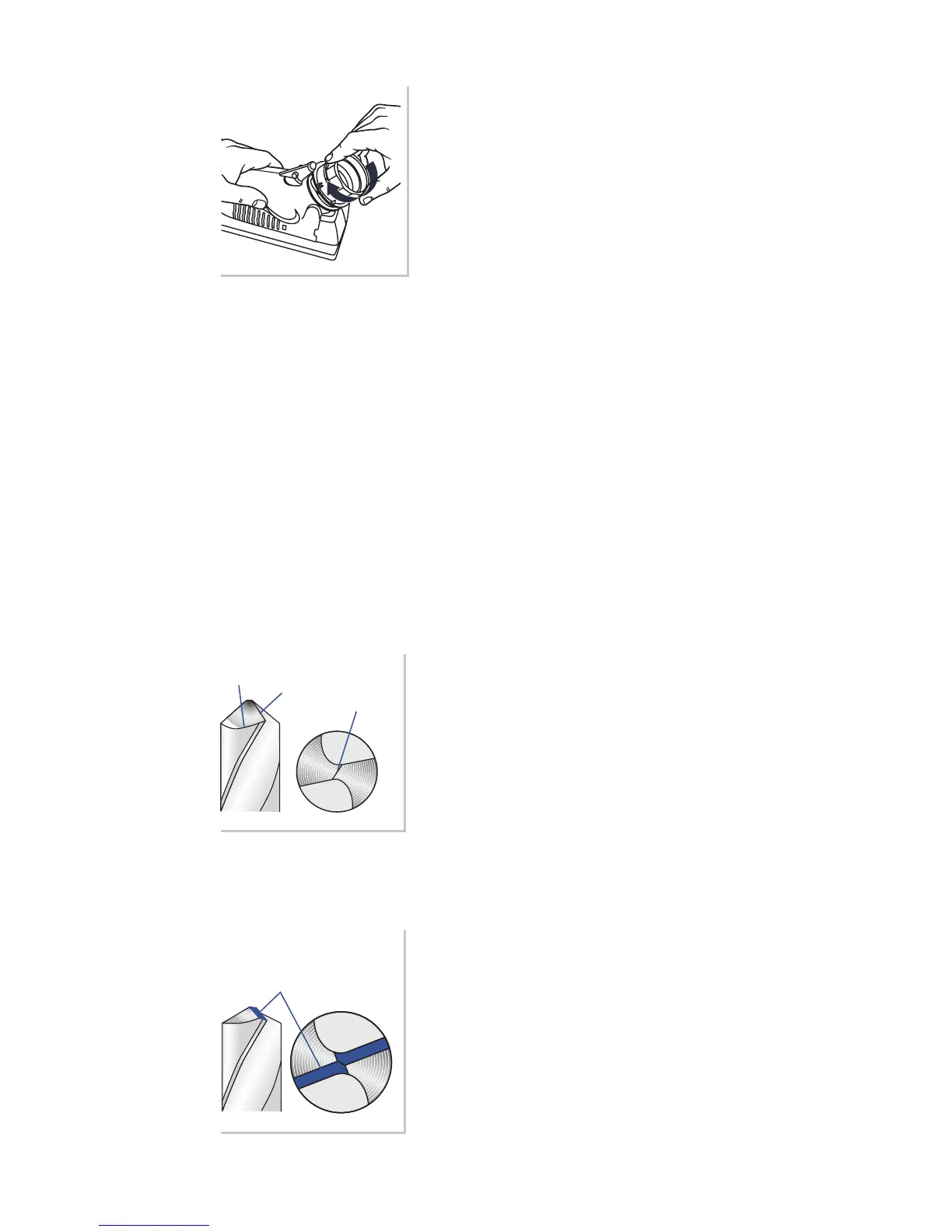

Turn clockwise to sharpen.

Making sure that the Chuck rests

rmly against the Cam Guide, turn the

Chuck from white line to white line in

a smooth and even motion. For best

results, sharpen until there is no more

grinding noise, allowing the machine

to complete its sharpening cycle.

The number of half-turns needed to

sharpen the bit depends on its size.

• 3/32-inch bits—use 2 to 4 half-turns,

• 1/8-inch bits—use 4 to 6 half-turns,

• 3/8-inch bits—use 16 to 20 half-turns.

Note: Use just enough pressure to keep the Cam against the Cam

Guide. Let the machine do the sharpening.

Identifying Correctly Sharpened Drill Bits

(and what to do with those that aren’t!)

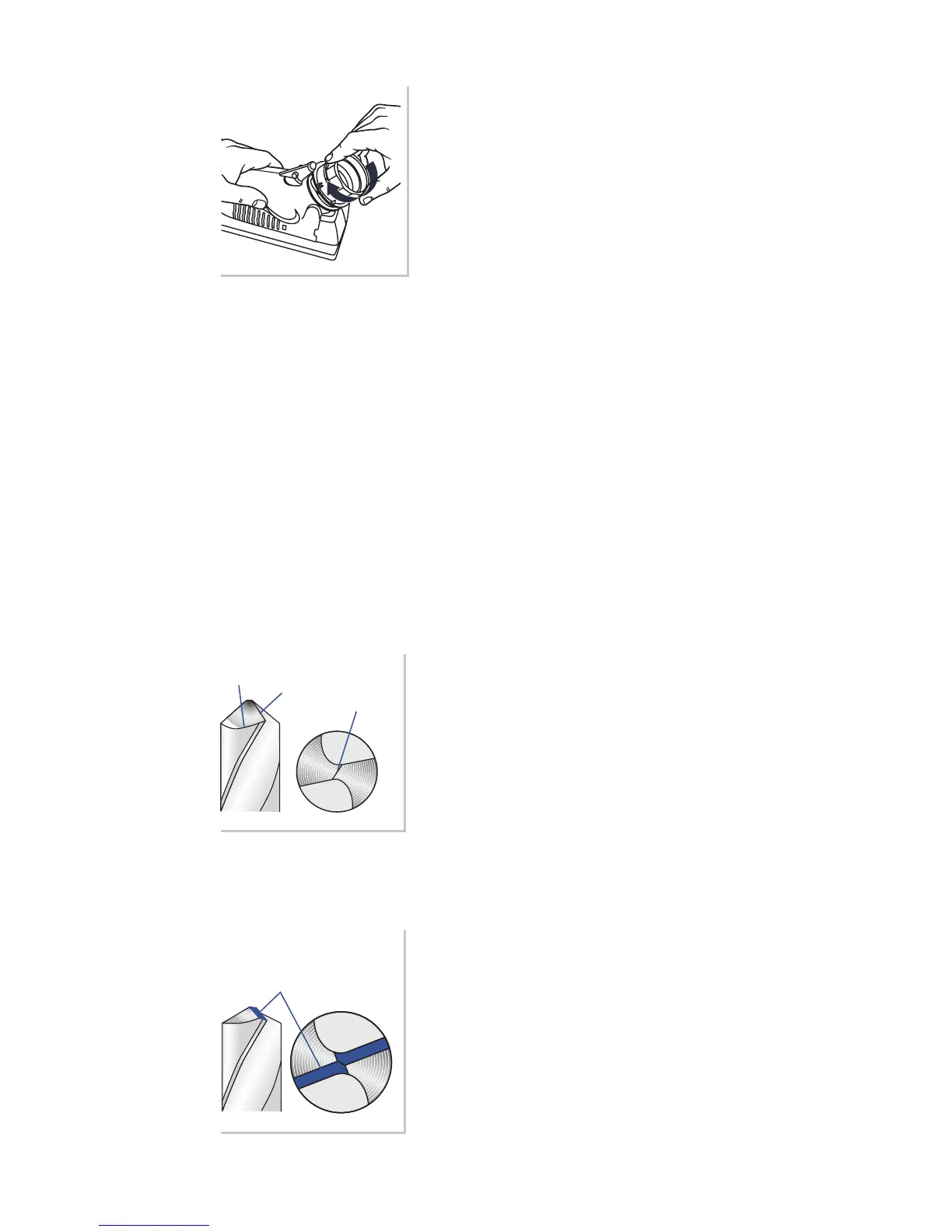

Correctly Sharpened Bits

The entire surface from the Cutting

Edge to the Heel will have a nely

ground surface without ridges or in-

dentations. The Heel will always be

lower than the Cutting Edge (positive

relief).

Cause

Alignment Fingers did not position

the drill bit properly in the aligning

process.

Solution

Realign the drill bit carefully by

following steps 1 through 4 under

Aligning the Drill Bit.

Heel

Cutting

Edge

Chisel

Point

Problem

The Chisel Edge

is ground flat.

Loading...

Loading...