Certified FLASH-R

20/27

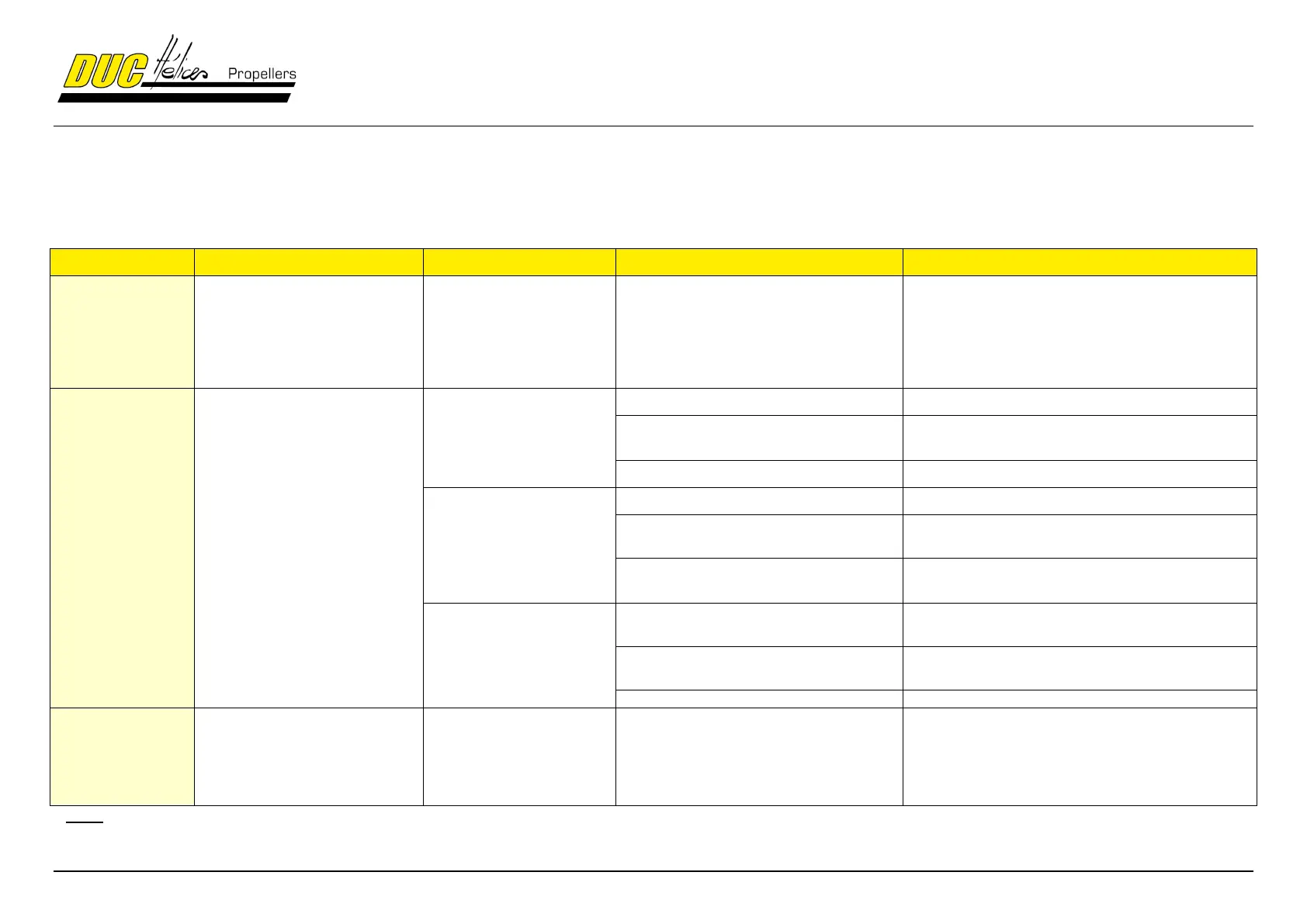

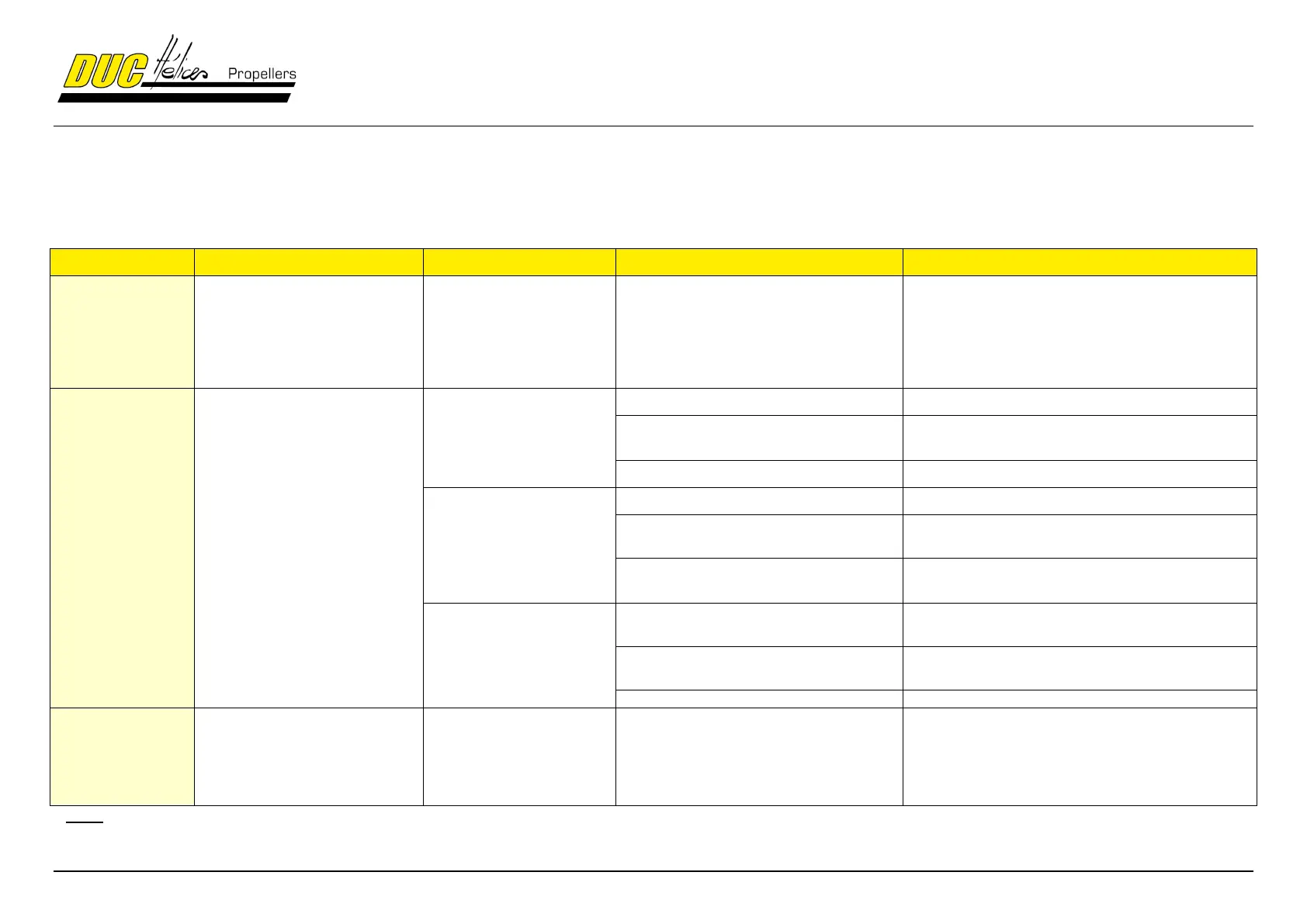

Regular maintenance (by the user) 7.3.

For a safety use of the FLASH propellers, it is necessary that the user performs regular maintenance to detect any abnormalities.

Frequency of checking: Each pre-flight

Fixation

of the propeller

Manually maintaining the tip of a blade

of the propeller, shake it firmly to feel

if a too much clearance appears in the

setting of the propeller.

Propeller fixation screws

Clearance in the propeller fixation

Stop propeller use and apply these corrective actions

Check screws.

If necessary, change the propeller fixations screws & Check

all the mounting to avoid problems.

Check visually the entire propeller

without dismantling (blade root,

Inconel leading edge, surface of the

blade, spinner, hub, etc.)

Big scratch/marking on the blade

Stop blade use*. You have to change the blade.

Small scratch/marking on the blade

If small marking without deformation, continue to use it.

Stop blade use*. You have to change the blade.

Shielding leading edge in

Inconel

Stop blade use*. You have to change the blade.

Significant impact: deep scratches, break,

deformation

(see. paragraph 7.5.)

Stop blade use*. You have to change the blade.

Low impact: not deep scratches

(see. paragraph 7.5.)

No mechanic risk, continue to use it.

Significant impact: deep scratches

Local delamination

(see. paragraph 7.5.)

Stop blade use*. You have to change the blade.

Low impact: not deep scratches, small scratch,

small impact

(see. paragraph 7.5.)

No significant risk, continue to use it.

Check visually the fixation screws of

the spinner

Check the screws. If necessary, change it.

Tighten the screws to proper torque with wrench

A marking paint of all the screw/washer/hub after tightening

can be done to help make a visual check outside of the

general maintenance.

* Nota: All the blades are balanced together. When a blade is changed, the blade has to be balanced to keep this balancing. For this, contact the DUC Hélices company.

Loading...

Loading...