ISO 9001 : 2015

N° TC EASA : EASA P.038

N° Part 21G EASA : FR.21G.0273

21/27

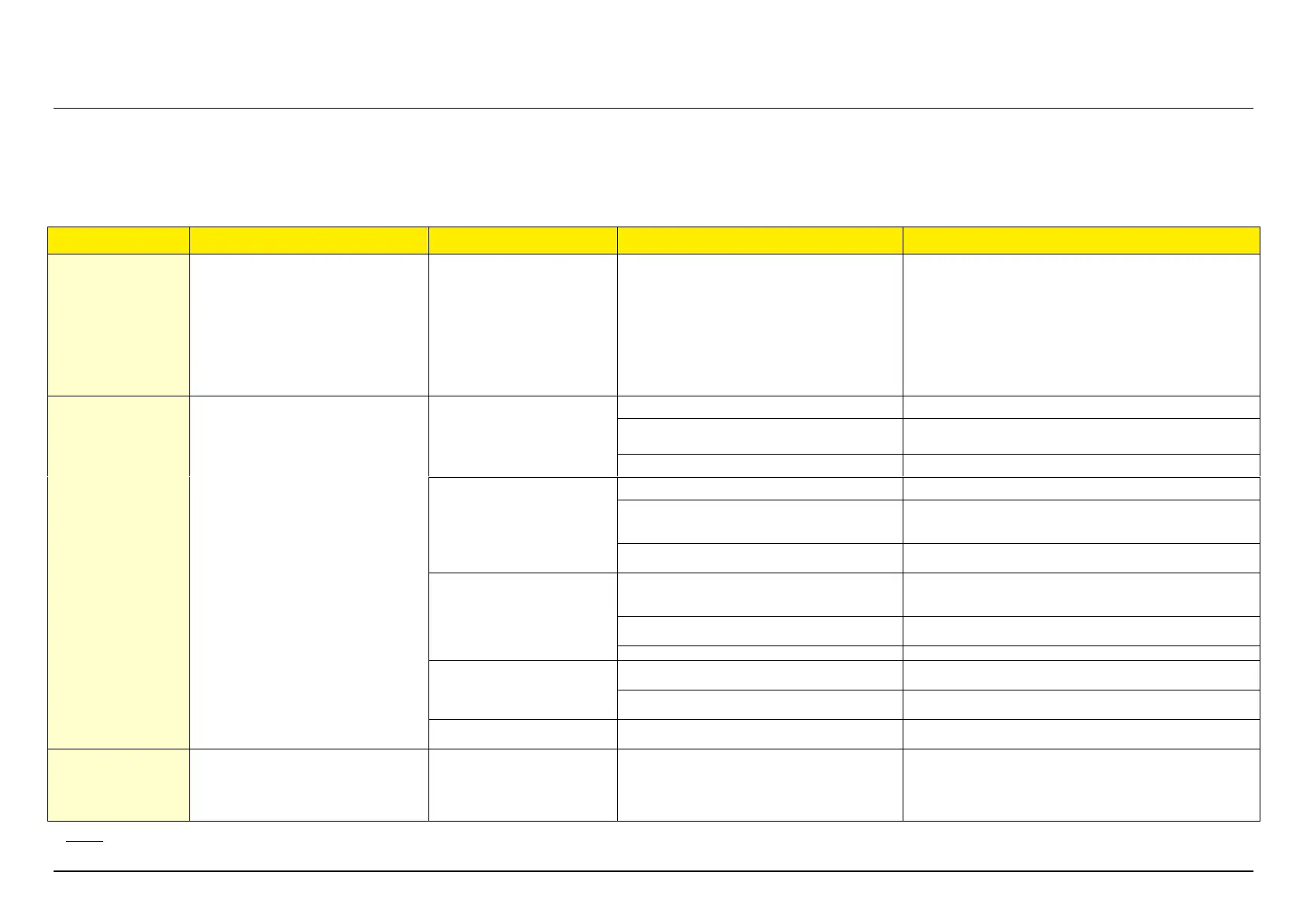

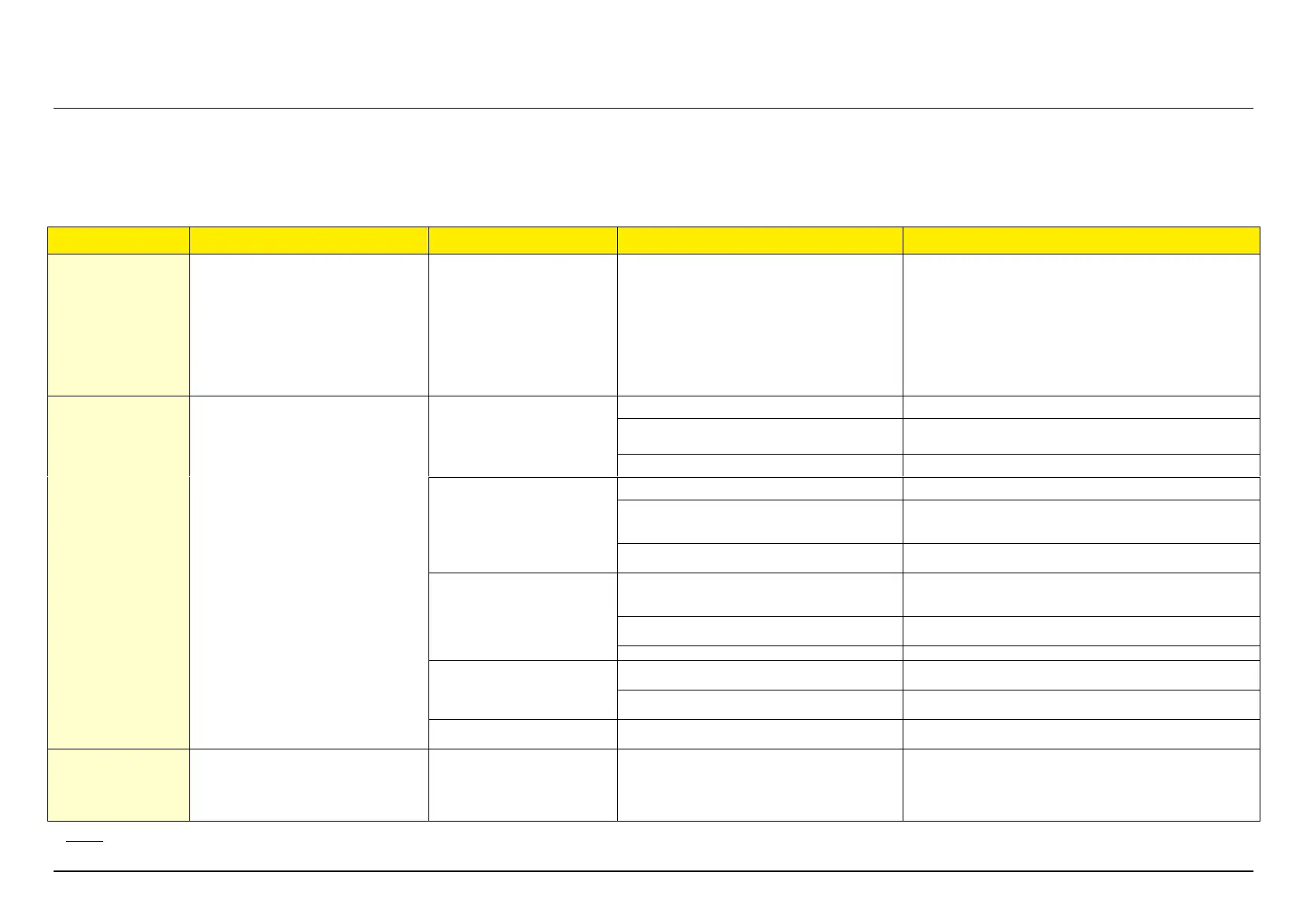

Maintenance of 100 hours or yearly maintenance. 7.4.

A propeller general check by the user or a certified aeronautic workshop must be done from time to time. During this check, clean the propeller.

Frequency of checking: 100 hours or yearly

Fixation

of the propeller

By removing the spinner of the

propeller, check the proper tightening of

the screws with a torque wrench.

Propeller fixation screws, hub

screws

Play/Gap in the propeller fixation

Stop propeller use and apply these corrective actions

Check screws.

If necessary, change the propeller fixations screws & Check

all the mounting to avoid problems. These screws of the hub

should be tightened to proper torque, defined in the

installation instructions attached.

Paragraph 5.3. Setting of the propeller &

Finalization of the installation, step 7.

Visual check of the propeller (Blade

root, hub, spinner, shielding leading

edge in Inconel …)

Big scratch/marking on the blade ring

Stop blade use*. You have to change the blade.

Small scratch/marking on the blade ring

If small marking without deformation, continue to use it.

Stop blade use*. You have to change the blade.

Shielding leading edge in

Inconel

Stop blade use*. You have to change the blade.

Significant impact: deep scratches, break,

deformation

(see. paragraph 7.5.)

Stop blade use*. You have to change the blade.

Low impact: Non-deep scratches

(see. paragraph 7.5.)

No mechanic risk, continue to use it.

Important impact: Crack, deep impact, local

delamination

(see. paragraph 7.5.)

Stop blade use*. You have to change the blade.

Low impact: not deep scratches

(see. paragraph 7.5.)

No significant risk, continue to use it.

Stop using this part.

Change the half-hub

Stop using this part.

Change the half-hub

Nylstop self-locking nut is damaged

Stop using this part.

Change the Nylstop self-locking nut

Check visually the correct fixing of the

spinner and its fixing bolts

Check the screws. If necessary, change it.

Tighten the screws to proper torque with wrench

A marking paint of all the screw/washer/hub after tightening

can be done to help make a visual check outside of the

general maintenance.

* Nota: All the blades are balanced together. When a blade is changed, the blade has to be balanced to keep this balancing. For this, contact the DUC Hélices company.

Loading...

Loading...