20

Basic Calibration Procedure (Continued)

Hand Crank Turns for Seed Rate Calibration

The tables represented below are for arable conditions (worked ground) and

are calculated to indicate an average situation. If there is any doubt as to the

accuracy of these figures for the conditions, it is advisable to run checks on

the calibration figures listed. Refer Page 22, (Wheel Slip Deviations).

9 Weigh the seed collected during the test in kilograms.

Caution: Scales must be accurate to 2 grams, as any error will be multiplied

by either 10 or 40, giving inaccurate calibration results.

10 Calculate the seed rate by multiplying the kgs previously collected x 40 (1/40th

ha method) or x 10 (1/10th ha method) depending on the requirement. If the

resultant calculation does not produce the desired seed rate use the enclosed

seed rate calculator disc to determine the correct gearbox setting.

Refer Use of Seed Rate Calculator Page 21.

Suggestion: To be on the safe side and until confidence has been gained

with the method of calibration it is advisable to conduct a second test at the

newly determined gearbox setting.

11 Where a coated seed is used it is advisable to check the calibration after

1 hectare as dressings can tend to create a coating on the seed metering

wheels thus changing the the flowing properties of the seed which in turn

alters the seed rate.

For

1

/

40

Hectare (250m

2

) Calibration

Seed Rate = Actual Seed Collected (kg) x 40

For

1

/

10

Hectare (1000m

2

) Calibration

Seed Rate = Actual Seed Collected (kg) x 10

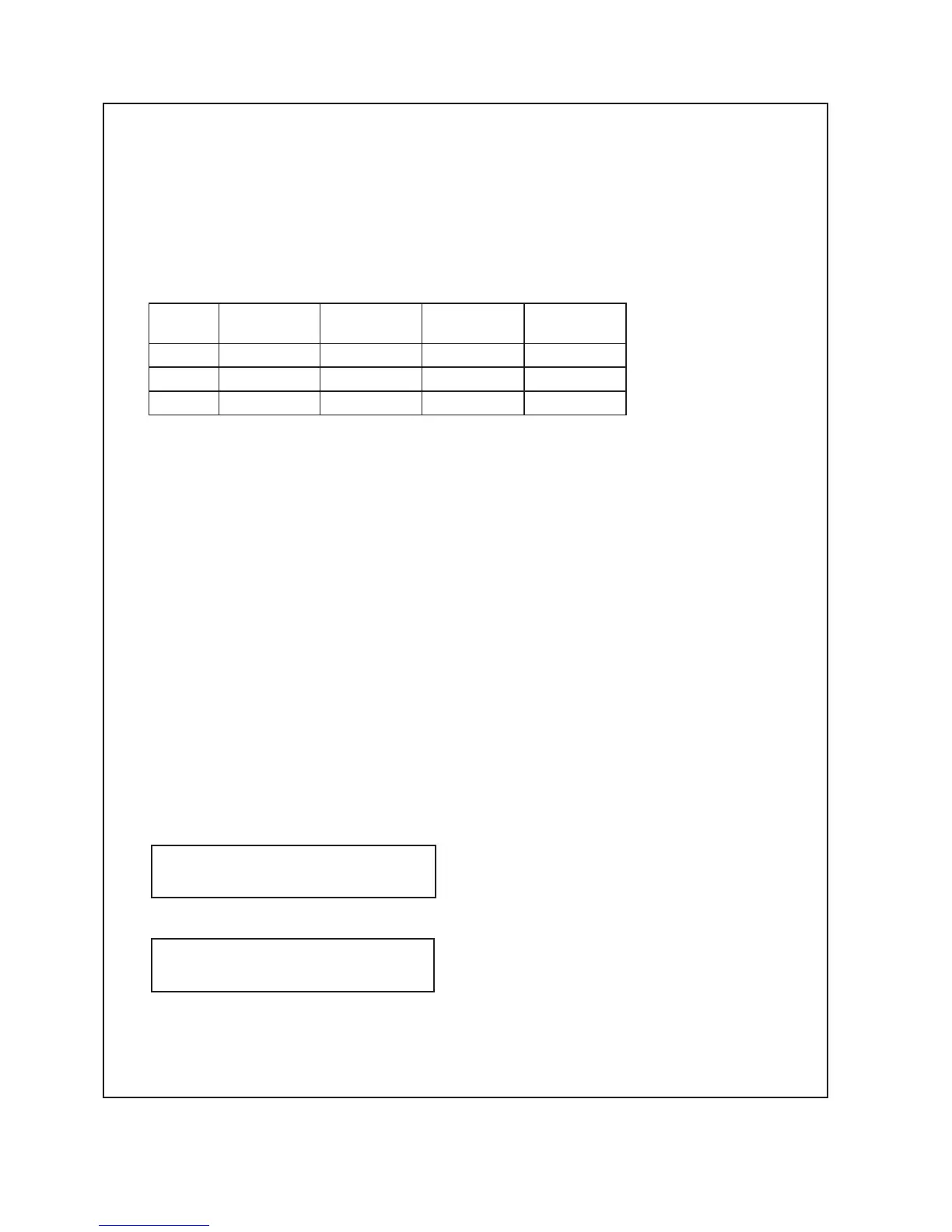

Machine

Size

Row

Spacing(mm)

Sowing Width

(m)

Turns for 1/40

Hectare

Turns for 1/10

Hectare

14 Run 148.5 2.079 29 114

16 Run 148.5 2.376 25 100

18 Run 148.5 2.673 22 89

Loading...

Loading...