35

Pt. No. 67392

Issue 0918

Calibration Chart and Handy Hints

Basic Calibration Procedure

Seed Calibration

The calibration test should be done to confirm the required seed rate and is done with the

drill stationary and level.

Seed Calibration Procedures

1 Place the calibration tray in the brackets

2 Position all the clear plastic seed diverters to redirect the seed into the calibration

tray

3 Set Shutter Slide

4 Set Bottom Flap

5 Disconnect/connect Agitator Shaft

6 Select gearbox setting

7 Place the crank handle over the hex drive and turn anti-clockwise until the seed

flows consistently from all seeder units then empty into the seedbox.

8 Turn the crank handle anti-clockwise the required number of revolutions.

9 Weigh seed (scales must be accurate to within 2 grams)

10

HANDY HINTS

Keep a constant pace during calibration turns

Bottom Flap: check gap setting (0.3mm) regularly to avoid inconsistent seeding

and or seed damage. REFER TO MANUAL

For products not on sowing chart choose a similar product

For accurate seeding, ensure jockey wheel is inflated to maximum pressure shown

on the tyrewall

Keep turning in ground to a minimum

When fitted, disc opener should run approx 20mm deeper than boot

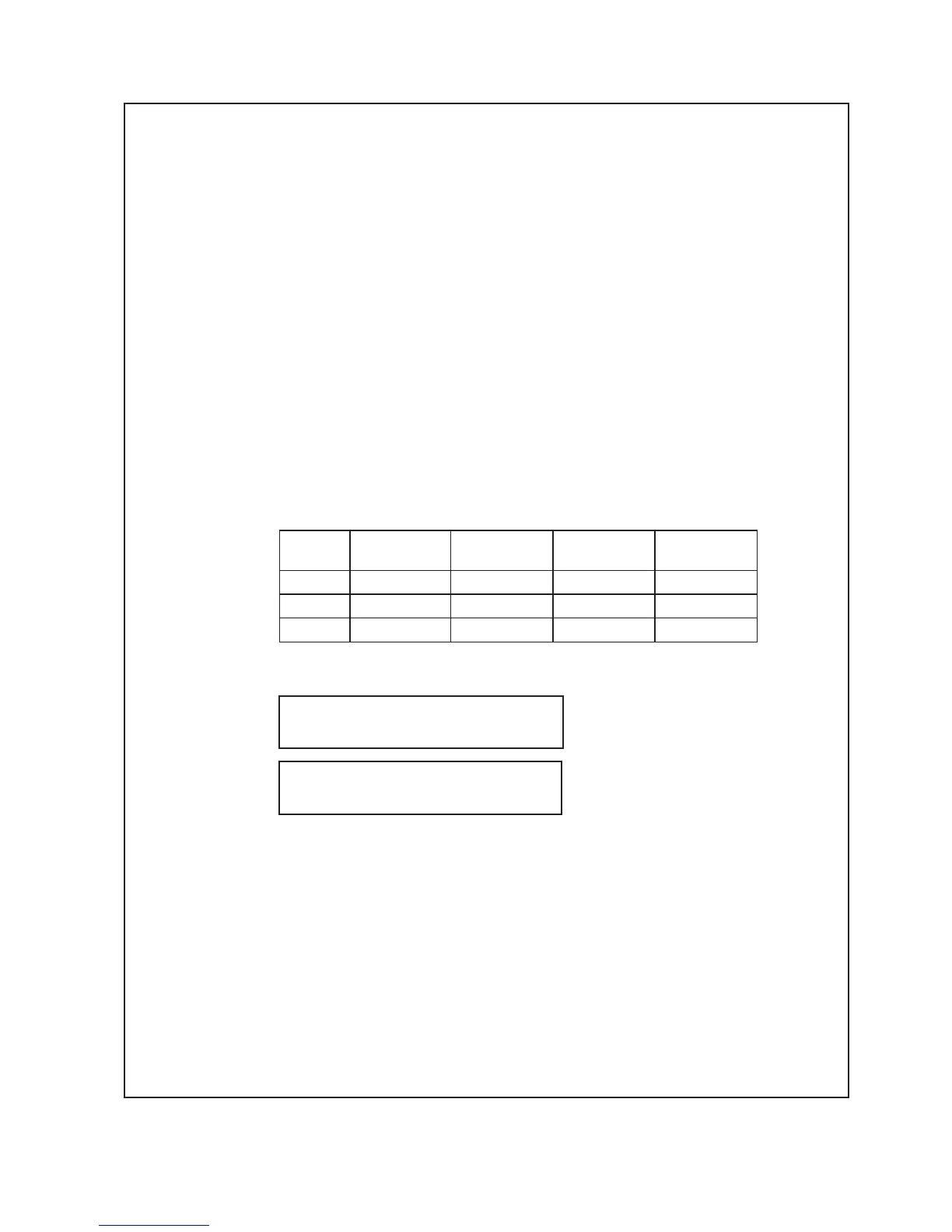

For

1

/

10

Hectare

Seed Rate = Actual Seed Collected (kg) x 10

For

1

/

40

Hectare

Seed Rate = Actual Seed Collected (kg) x 40

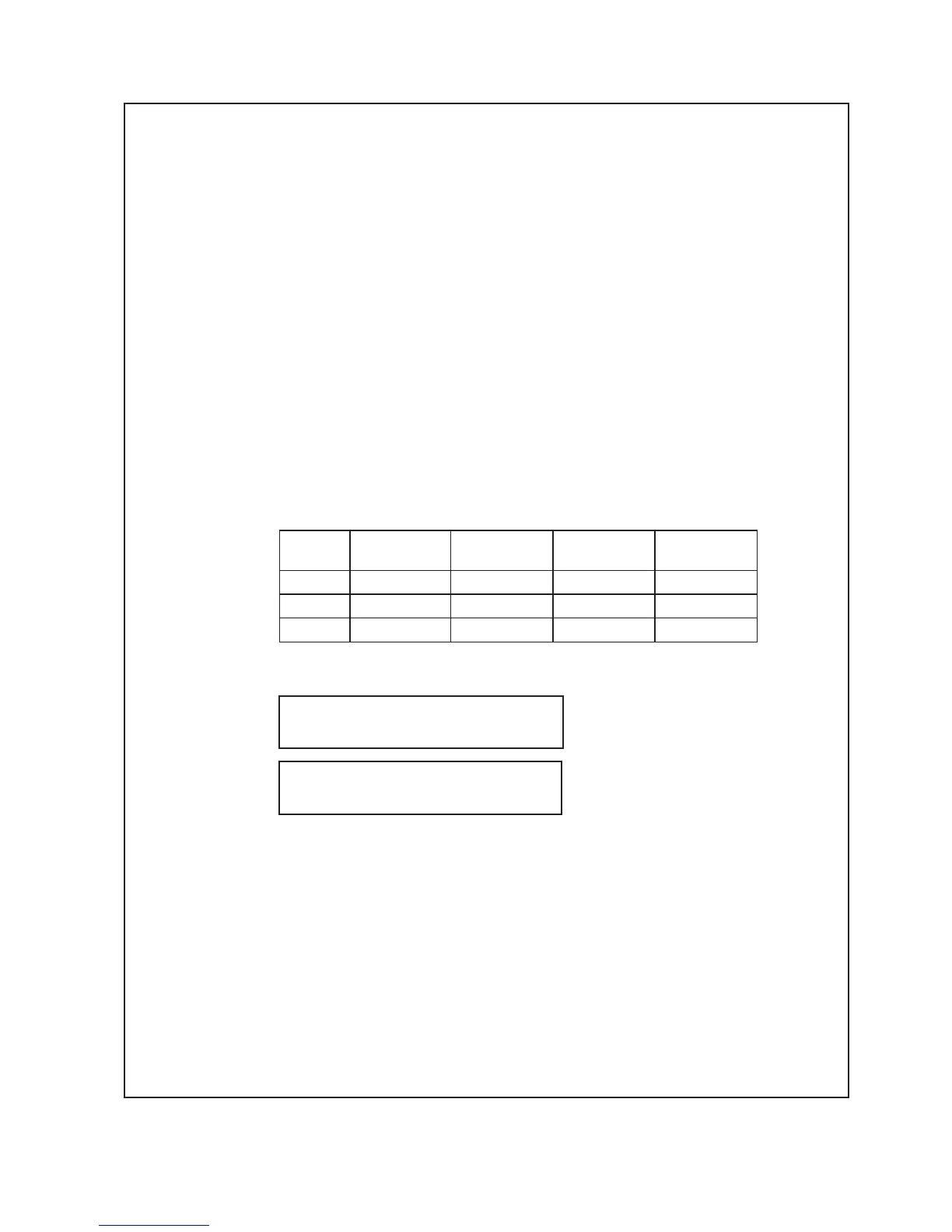

Machine

Size

Row

Spacing(mm)

Sowing Width

(m)

Turns for 1/40

Hectare

Turns for 1/10

Hectare

14 Run 148.5 2.079 29 114

16 Run 148.5 2.376 25 100

18 Run 148.5 2.673 22 89

Loading...

Loading...