30

Maintenance Schedule

(

Refer also to Summary Chart, above)

1. Bolted Connections

All bolted connections of the machine should be checked after the first 3 to 5 hours of operation and

retightened if necessary and thereafter at regular intervals. It is suggested that this is done every 500

hectares or annually, whichever occurs first.

2. Gearbox

The oil level in the gearbox can be seen in the oil gauge window. Changing the gearbox oil is

recommended once a year or sooner if the oil is discoloured. For draining, remove the drain plug at

the bottom of the gearbox and the fill plug at the top. Replace drain plug before refilling

Castrol Oil Agri Trans Plus or equivalent* should be used.

The total filling capacity is 1.25 litres.

DO NOT OVERFILL.

*Oil Specification to meet the requirements of : SAE 10W-30, API GL-4, Massey Ferguson M1143,

John Deere J20C, J20D, Case MS 1207, Ford/New Holland M2C-134D, M2C-86 A/B/C

3. Hydraulics

Ensure hydraulic couplings (male & female) are clean before connecting. Dirty couplings will result in

hydraulic oil contamination and hydraulic seal and bore damage which will cause oil leakage past the

seals.

No filter is fitted to the hydraulic system. If the hydraulic fittings and the oil supply are not going to

be kept clean then it is recommended that a filter be fitted to prevent hydraulic cylinder damage.

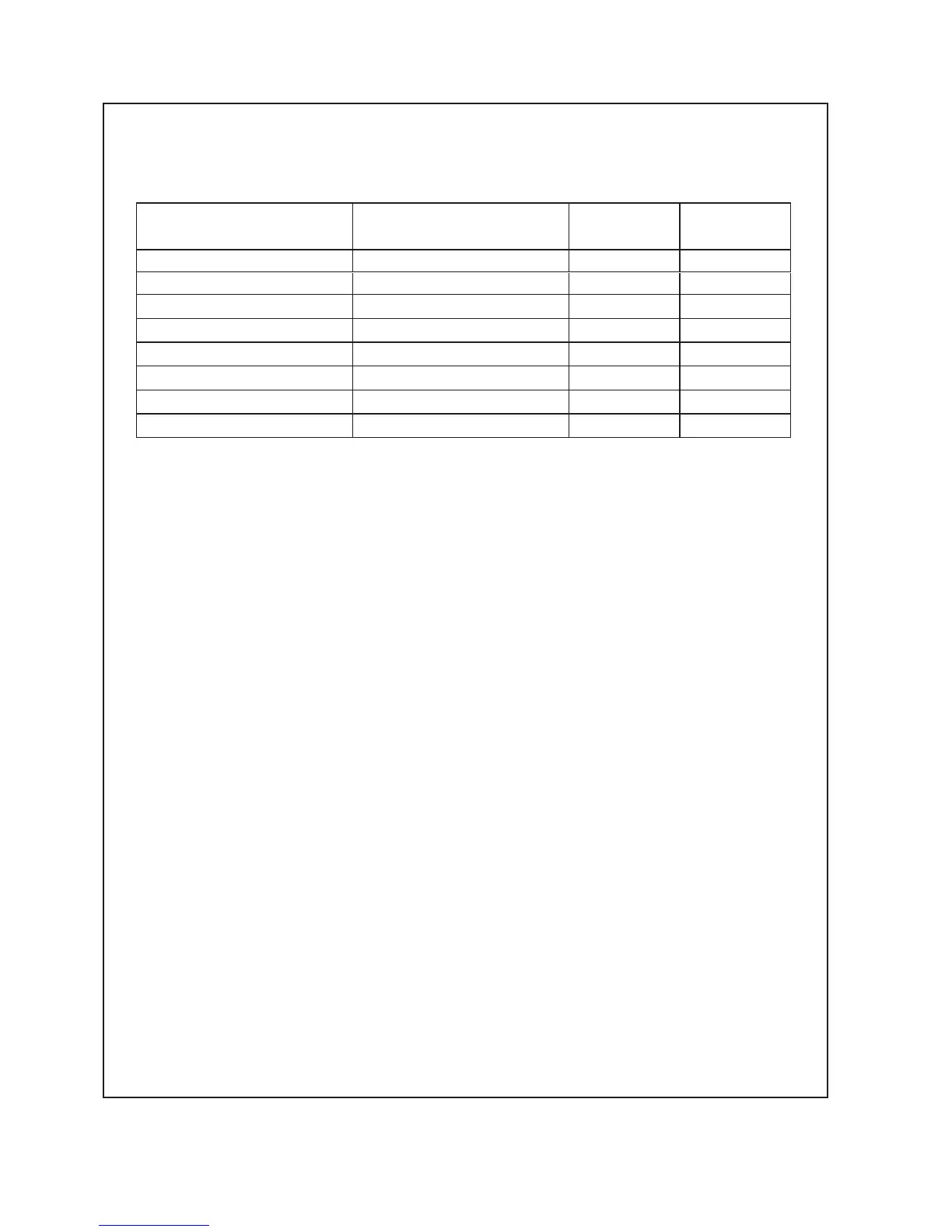

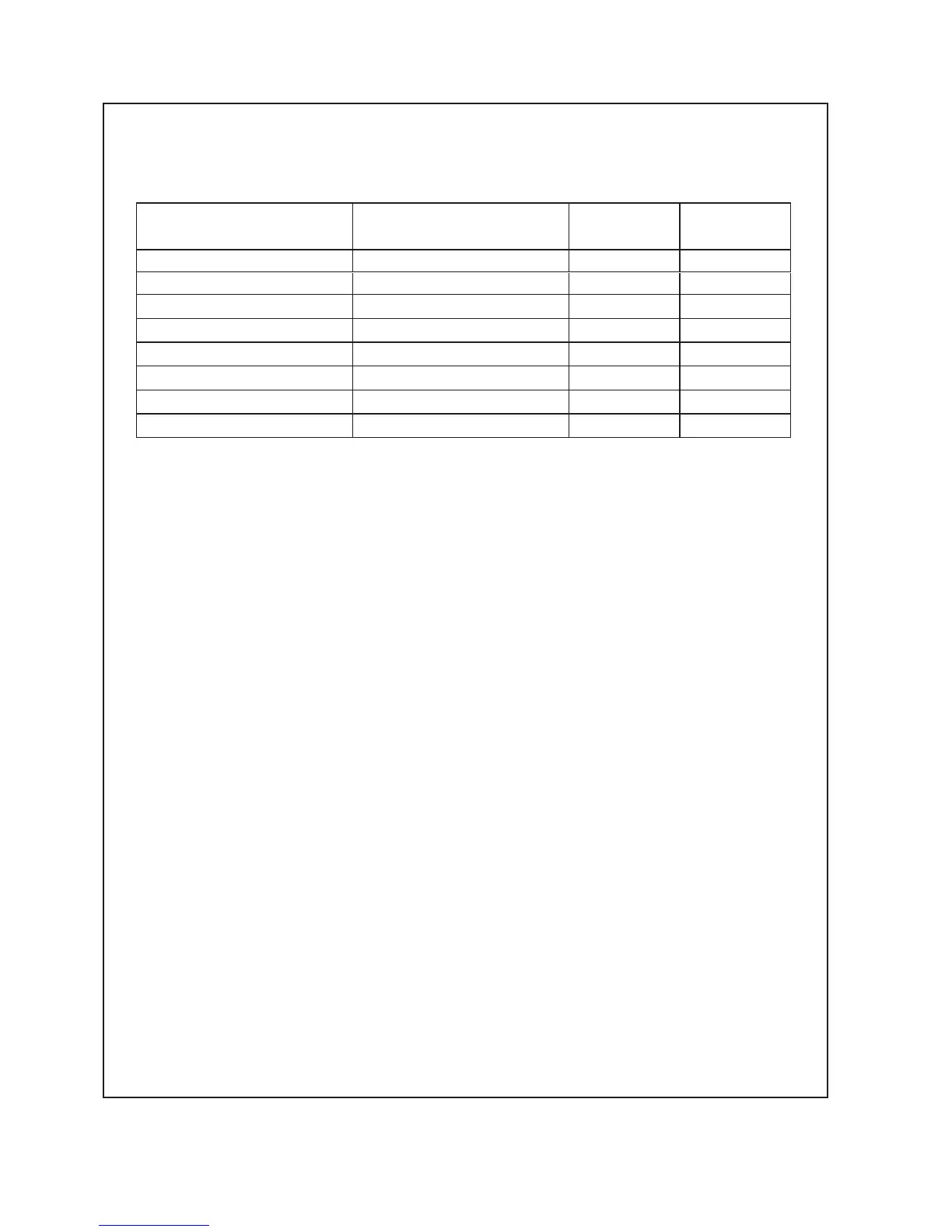

Maintenance & Care - continued

Components

Daily Weekly Pre Season

(or after 20Ha) (or after 75Ha) (or 500 Ha)

Disc Openers ●●●

Seeders/Agitators/Bottom Flaps ●●●

Pivot Pin Fasteners ●●

Roller Chains ●●

Gearbox ●●

Hydraulics (Oil Leaks) ●●

Tyre Pressures ●●

Bolted Connections ●

Loading...

Loading...