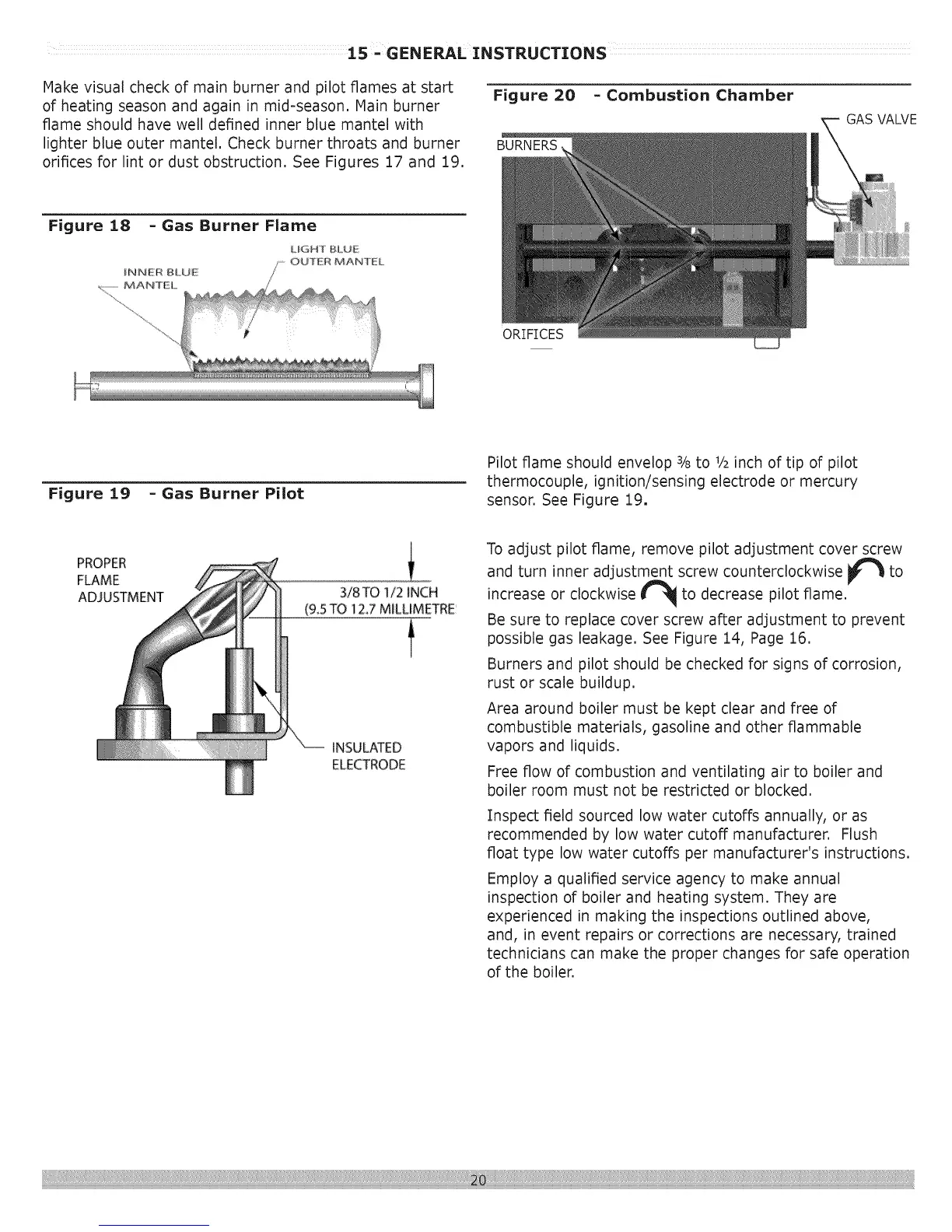

Makevisualcheckof mainburnerandpilotflamesatstart

ofheatingseasonandagaininmid-season.Mainburner

flameshouldhavewelldefinedinnerbluemantelwith

lighterblueoutermantel.Checkburnerthroatsandburner

orificesforlintor dustobstruction.SeeFigures17and 19.

Figure 20

BURNERS,

- Combustion Chamber

GAS VALVE

ORIFICES

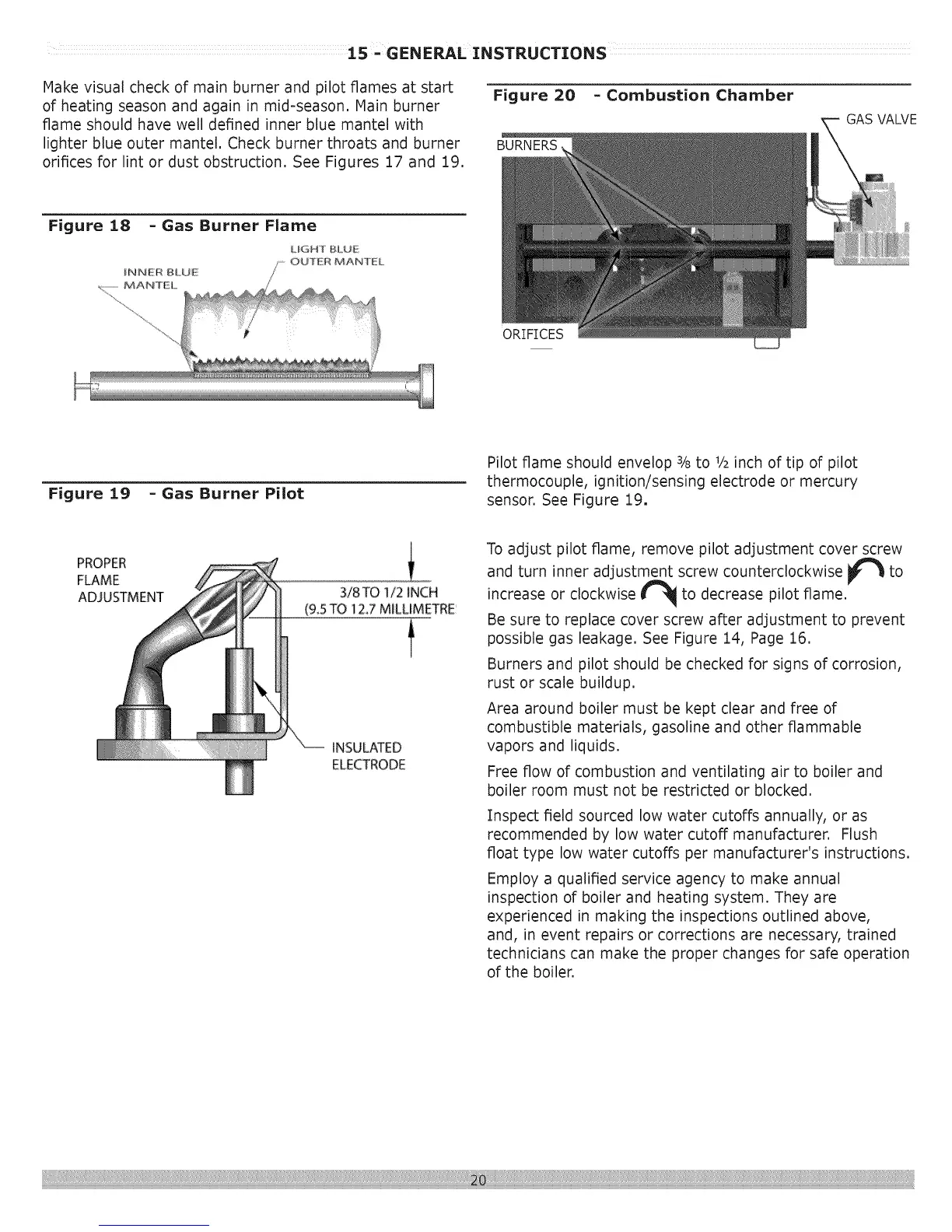

Figure 19 - Gas Burner Pilot

Pilot flame should envelop 3/8to 1/2inch of tip of pilot

thermocouple, ignition/sensing electrode or mercury

sensor. See Figure 19.

PROPER

FLAME

ADJUSTMENT

3/8TO1/2 iNCH

(95 TO 1Z7 MILUMETRE

t

iNSULATED

ELECTRODE

To adjust pilot flame, remove pilot adjustment cover screw

and turn inner adjustment screw counterclockwise _ to

ir

increase or clockwise _ to decrease pilot flame.

Be sure to replace cover screw after adjustment to prevent

possible gas leakage. See Figure 14, Page 16.

Burners and pilot should be checked for signs of corrosion,

rust or scale buildup.

Area around boiler must be kept clear and free of

combustible materials, gasoline and other flammable

vapors and liquids.

Free flow of combustion and ventilating air to boiler and

boiler room must not be restricted or blocked.

Inspect field sourced low water cutoffs annually, or as

recommended by low water cutoff manufacturer. Flush

float type low water cutoffs per manufacturer's instructions.

Employ a qualified service agency to make annual

inspection of boiler and heating system. They are

experienced in making the inspections outlined above,

and, in event repairs or corrections are necessary, trained

technicians can make the proper changes for safe operation

of the boiler.

Loading...

Loading...