Operating and Maintenance Instructions

EN

LC.2 – LC.4 – LB.5 – LB.6 – LB.8 – LC.12 – LC.20

16

8702036 – 12/04/2016 – R.7 www.dvp.it

• connect to mains again and verify correct rotation direction of the pump (see chapt. 3.3.);

• let the pump run with closed intake for a few minutes and then, if necessary, top up oil if necessary.

HAZARD

Wear appropriate personal protection equipment to perform said operations.

HAZARD

Comply with local regulations regarding the collection and disposal of used or polluted oil.

6.2.3 CLEAN MOTOR FAN GUARD EAND CLEAN THE PUMP

Radiator, motor fan guard and the pump should be cleaned to remove any dust deposits.

This can be done using compressed air and a dry cloth.

Do not use fluids or substances other than those indicated.

HAZARD

Wear appropriate personal protection equipment to perform said operations.

6.2.4 CHANGE THE AIR EXHAUST FILTER

The air exhaust filter must be changed when it is damaged or clogged or when it has reached its authorised life as

per Chap 6.2.

Only use original DVP filters from the Air Exhaust Filter Kit (see Chap.6.3). Use of parts other than those approved

by DVP can cause deterioration of the pump.

The signs showing a filter is clogged or damaged are increased exhaust fumes, increased noise-level and

consumption of electricity (see Chap.9 points C and E).

It is possible to measure the level of clogging of the oil separator filter by looking at the ∆P of the filter with the pump

warm. On pumps equipped with a measuring point for ∆P it is possible to check the filter by attaching a gauge or

the accessory code SIF.2 to it. For pumps without this facility a measuring instrument can be connected in place of

the oil filler cap.

For a pump operating and with hot oil the filter is clogged if the value of ∆P is greater than 0.7bar (at sea level). If

this is the case the oil separator filter must be replaced.

6.2.5 CHANGE VANES

The instructions for replacing vanes are available upon request.

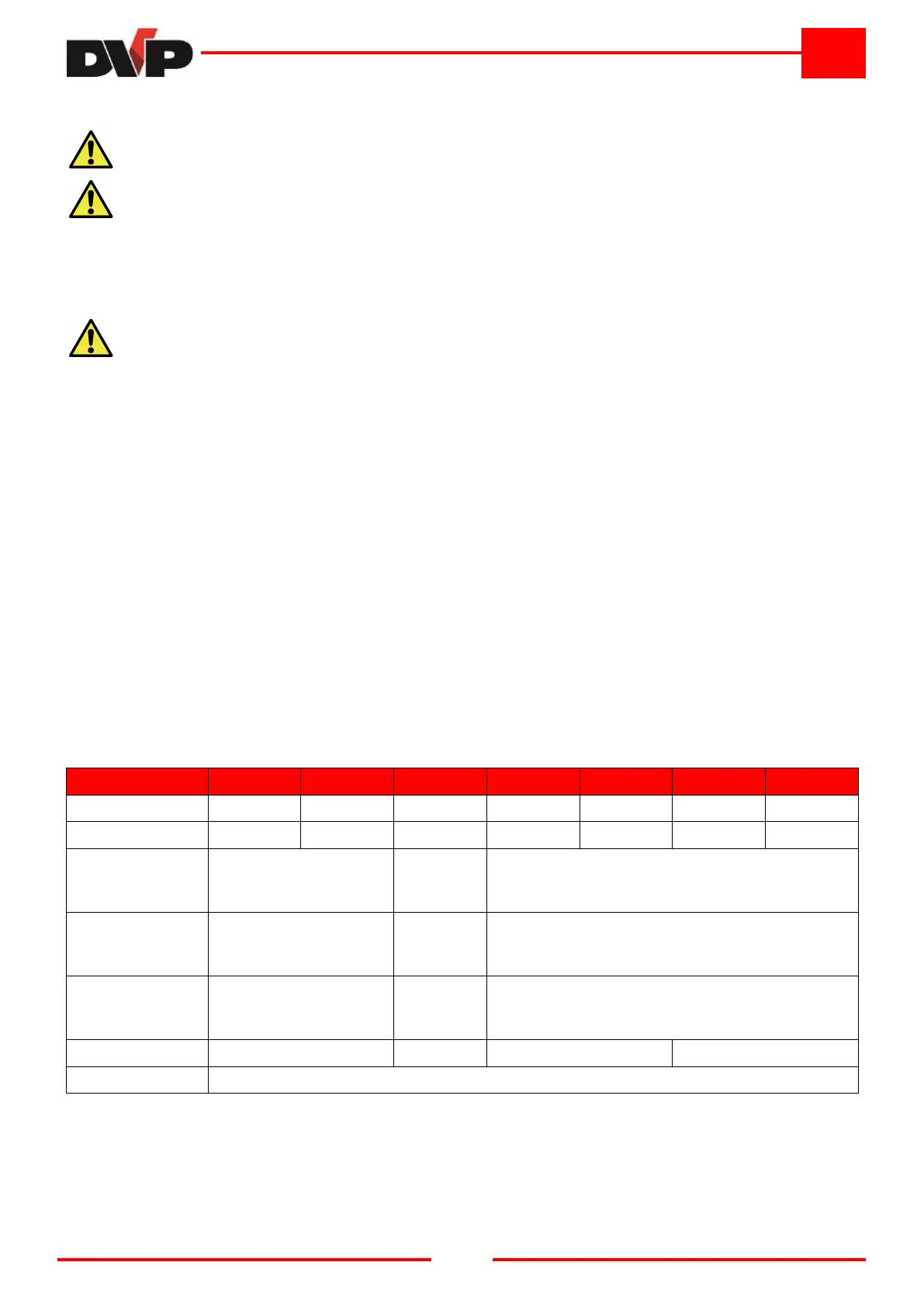

6.3 SPARE PARTS

Use Original Spare Parts to replace pump parts.

When purchasing spare parts, always quote the serial number and model of the pump (these can be found on the

identification plate) as well as the spare part purchase number.

DESCRIZIONE LC.2 LC.4 LB.5 LB.6 LB.8 LC.12 LC.20

Air exhaust filter kit

K9601069 K9601070 K9601062 K9601058 K9601055 K9601064 K9601066

Maintenance kit

K9601069/1

K9601070/1

K9601062/1

K9601058/1

K9601055/1 K9601064/1 K9601066/1

Oil 0,25 dm³

8811025 (BV32)

8831025 (SW40)

8812025

(BV68)

8832025

(SW60)

8811025 (BV32)

8831025 (SW40)

Oil 0,5 dm³

8811050 (BV32)

8831050 (SW40)

8812050

(BV68)

8832050

(SW60)

8811050 (BV32)

8831050 (SW40)

Oil 1 dm³

8811100 (BV32)

8831100 (SW40)

8812100

(BV68)

8832100

(SW60)

8811100 (BV32)

8831100 (SW40)

Oil sight glass

1105005 1105004 1105009 1105004

Check valve

Fitted

D.V.P. Vacuum Technology s.p.a. disclaims all responsibility for any deterioration of pump performance or for

damages caused due to use of non-original spare parts.

Loading...

Loading...