Operating and Maintenance Instructions

EN

LC.2 – LC.4 – LB.5 – LB.6 – LB.8 – LC.12 – LC.20

18

8702036 – 12/04/2016 – R.7 www.dvp.it

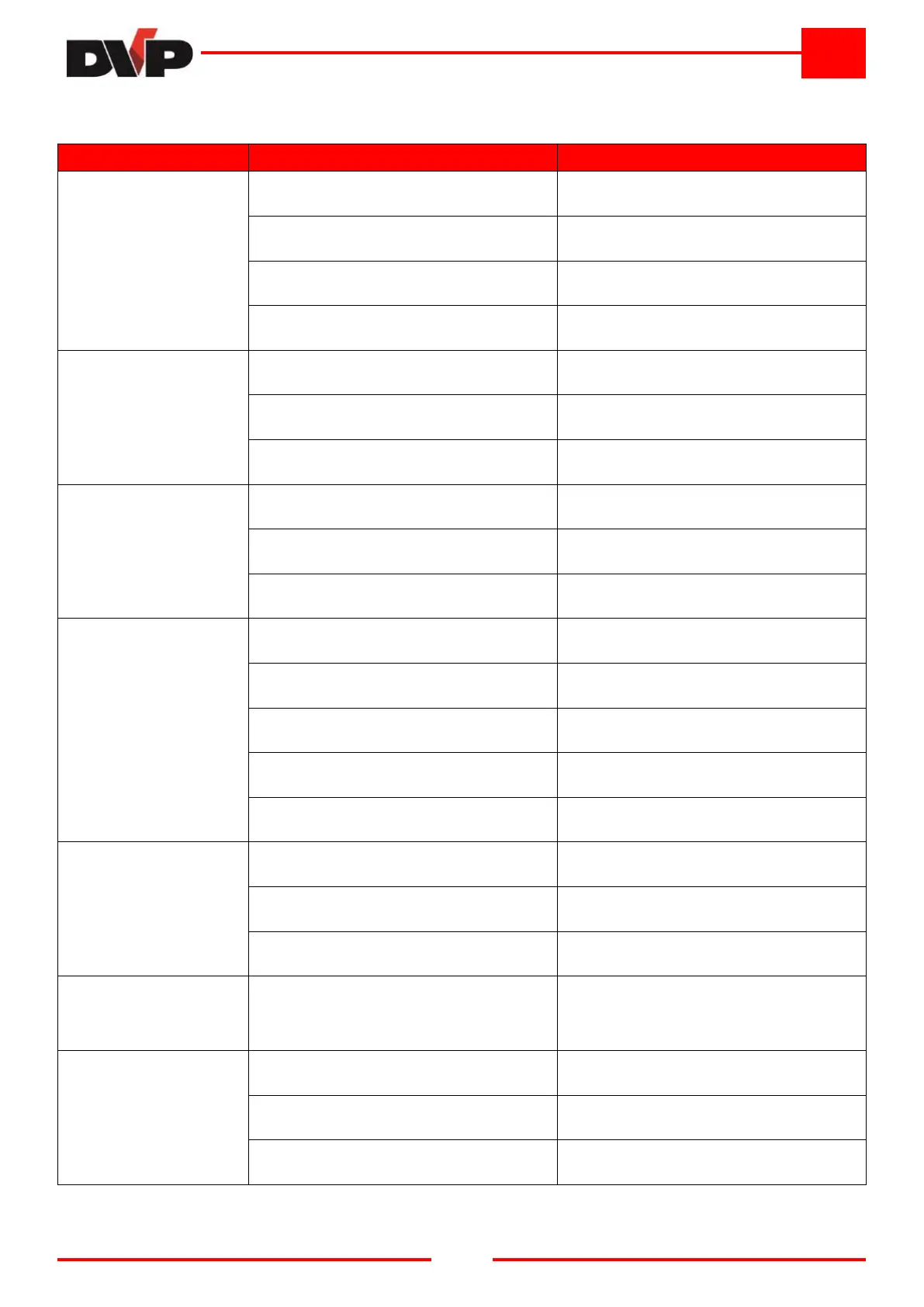

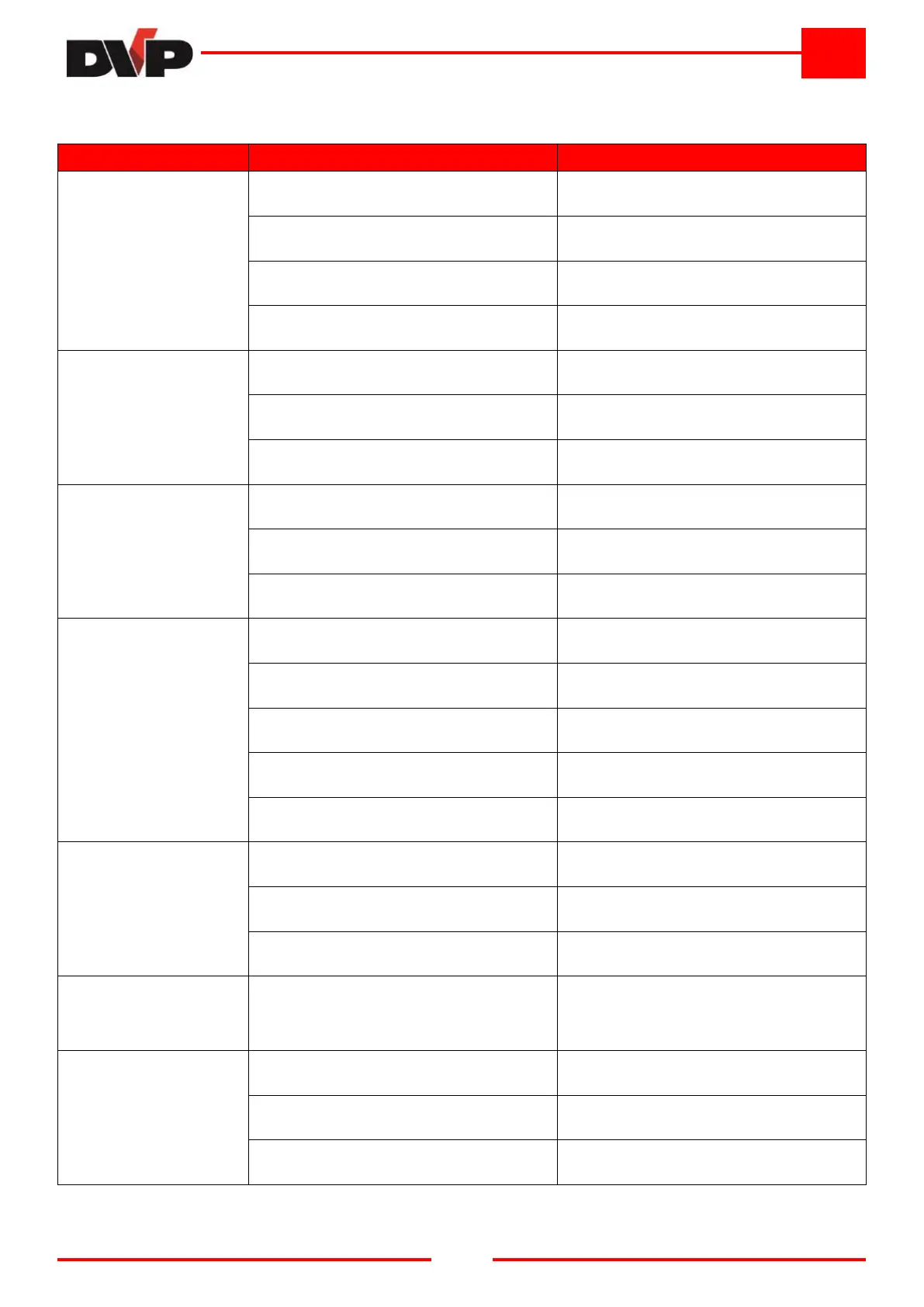

9 TROUBLESHOOTING

DAMAGE CAUSE REMEDY

(A)

The pump does not run

No voltage Provide power supply

Thermal switch has tripped Identify reason and activate switch

Room temperature is too low

Restore room temperature to allowed

range

Motor winding damaged Contact Service Department

(B)

The pump cannot

reach stated vacuum

Low oil in tank Top up oil

Oil contaminated Change oil

Discharge clogged Check couplings at outlet

(C)

Pump is noisy

Air exhaust filter clogged Change the air exhaust filter

Bearings damaged Contact Service Department

Vanes worn out Contact Service Department

(D)

Pump runs hot

Oil is not the suitable type Change oil

Poor room ventilation Install an auxiliary ventilator

Motor fan broken Contact Service Department

Wrong power supply to motor Check power supply

Discharge clogged Check couplings at outlet

(E)

High oil consumption

High working pressure

(close to atmospheric pressure)

Check oil level frequently

Pump runs hot See point “D”

Air exhaust filter clogged Change the air exhaust filter

(F)

Pump does not

maintain vacuum after

power-off

Check valve damage (if fitted) Contact Service Department

(G)

Pump leaks oil

Tank screws or plugs loosened Tighten screws or plugs

Tank gaskets damaged Contact Service Department

Oil sight glass not tightened Tighten the oil sight glass

Loading...

Loading...