21CC102/C/122/C/132/142/C M102EN4

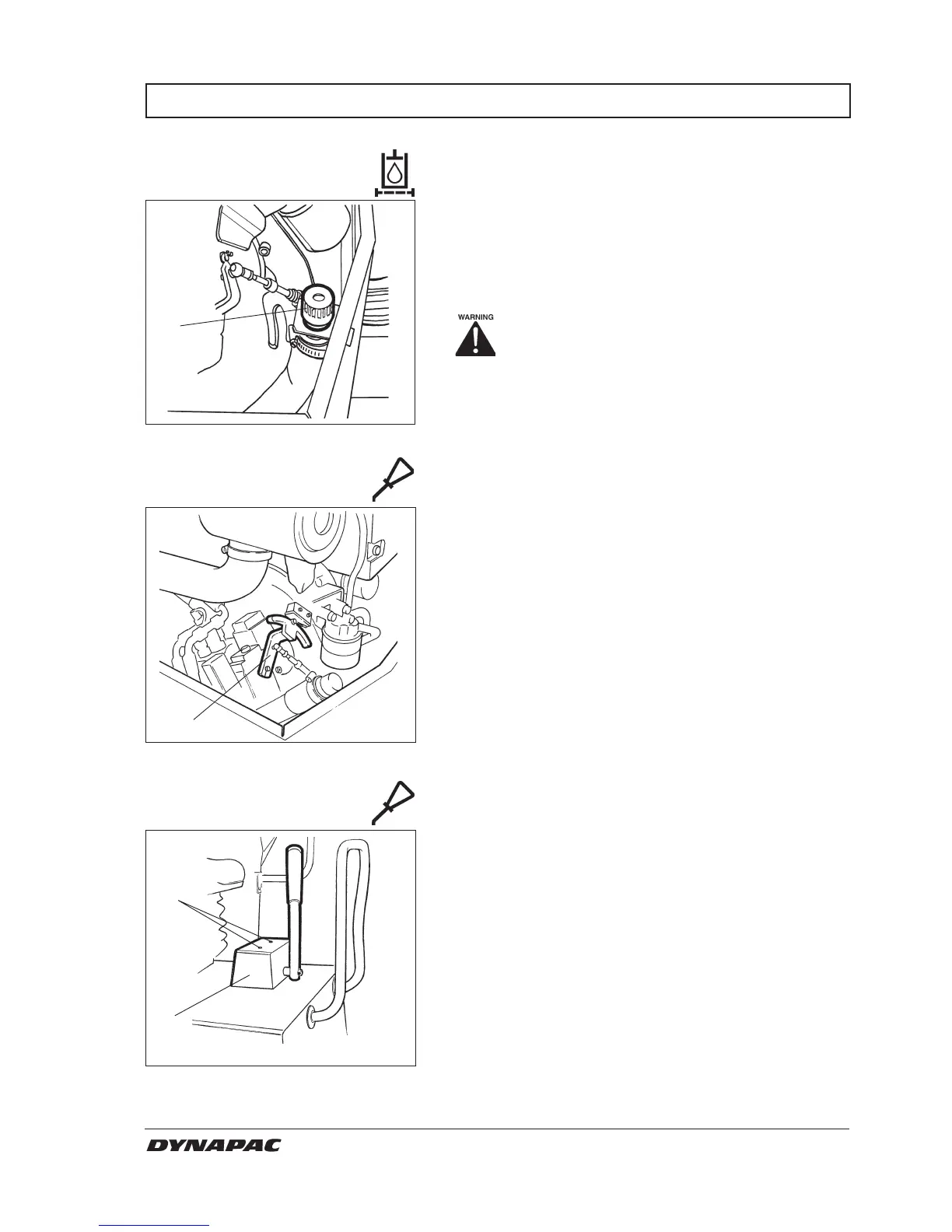

Unscrew and ensure that the reservoir cap is not

clogged; air must have unobstructed passage through

the cap in both directions.

If clogged in either direction, clean with a little diesel oil

and blow with compressed air until free passage is

assured, or replace the cap with a new one.

Wear protective goggles when working

with compressed air.

1

2

Fig. 31 Operator’s station

1.Forward/reverse lever

2.Fastening screws

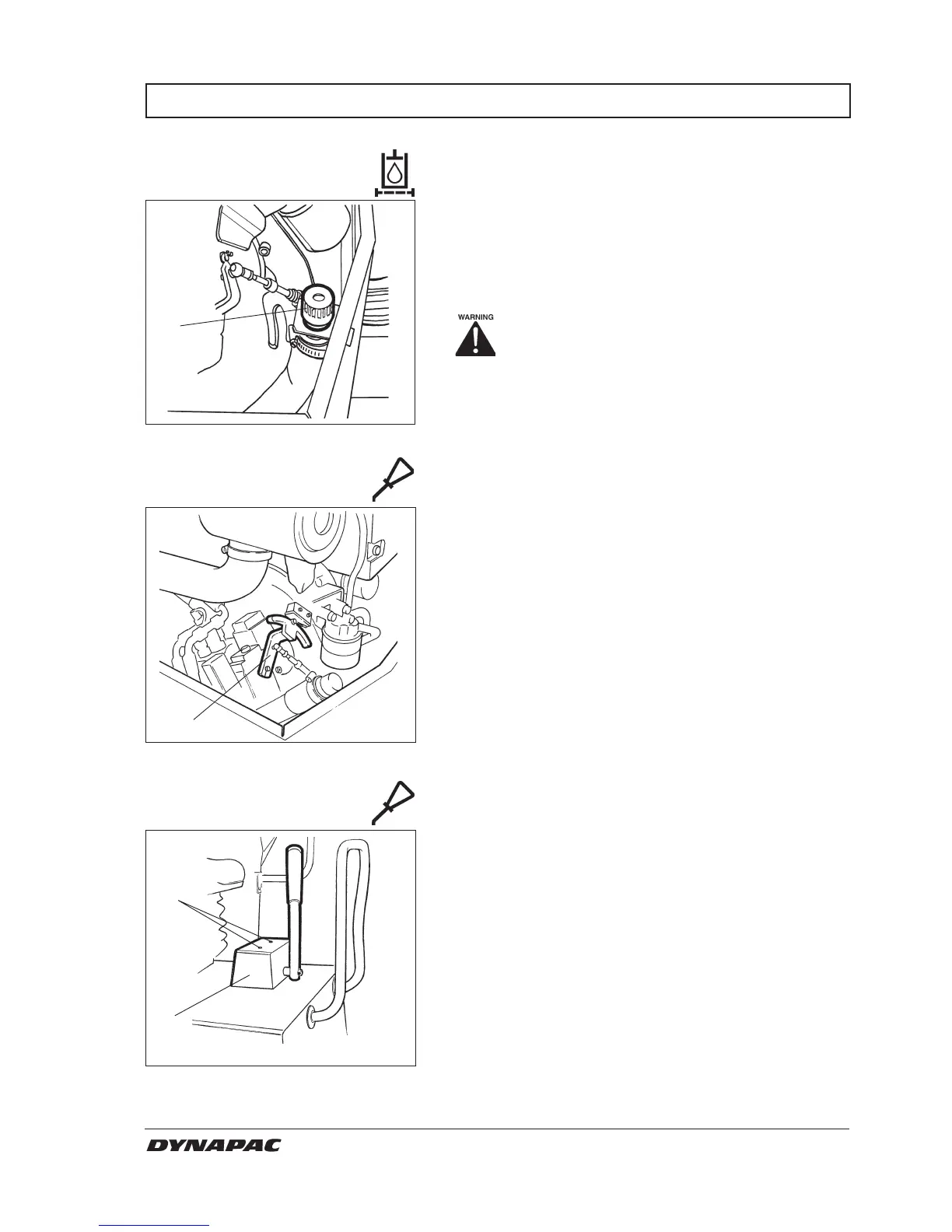

Lubricate the forward/reverse controls in the engine

compartment with a few drops of oil.

If the controls become sluggish after a long period of

use, remove the cover and the forward/reverse lever in

the operator’s station and lubricate the mechanism.

Lubricate the forward/reverse mechanism.

Unscrew the screws (2) in the top of the protective

cover (1), remove the cover and lubricate the

mechanism under the cover with oil.

Controls – Lubrication

Controls – Lubrication

1

Fig. 30 Engine compartment

1. Forward/reverse lever

EVERY 500 HOURS OF OPERATION (Every three months)

1

Hydraulic reservoir cap

– Check

Fig. 29 Engine compartment

1. Tank cap

Loading...

Loading...