P11P10

How We Got There

How do you

design a new legend?

Experiments, arguments,

tests, more experiments,

designs, prototypes ...

You can’t reinvent the wheel. But you can

change the spokes. In redesigning the

Contour range, we changed a lot of spokes.

We worked hard to retain the original’s

DNA; its character. But we also wanted

to provoke – so we gave our teams free

rein to experiment with different materials,

different techniques and different designs.

That meant scaring ourselves a little

sometimes. Like when we did some

A/B listening tests on small voice-coils

compared with our signature large ones.

That’s a big step. This time, it proved to be

a step too far – they just didn’t sound as

good as the technology we’ve been using

for years – but we didn’t simply discount

the idea. We listened.

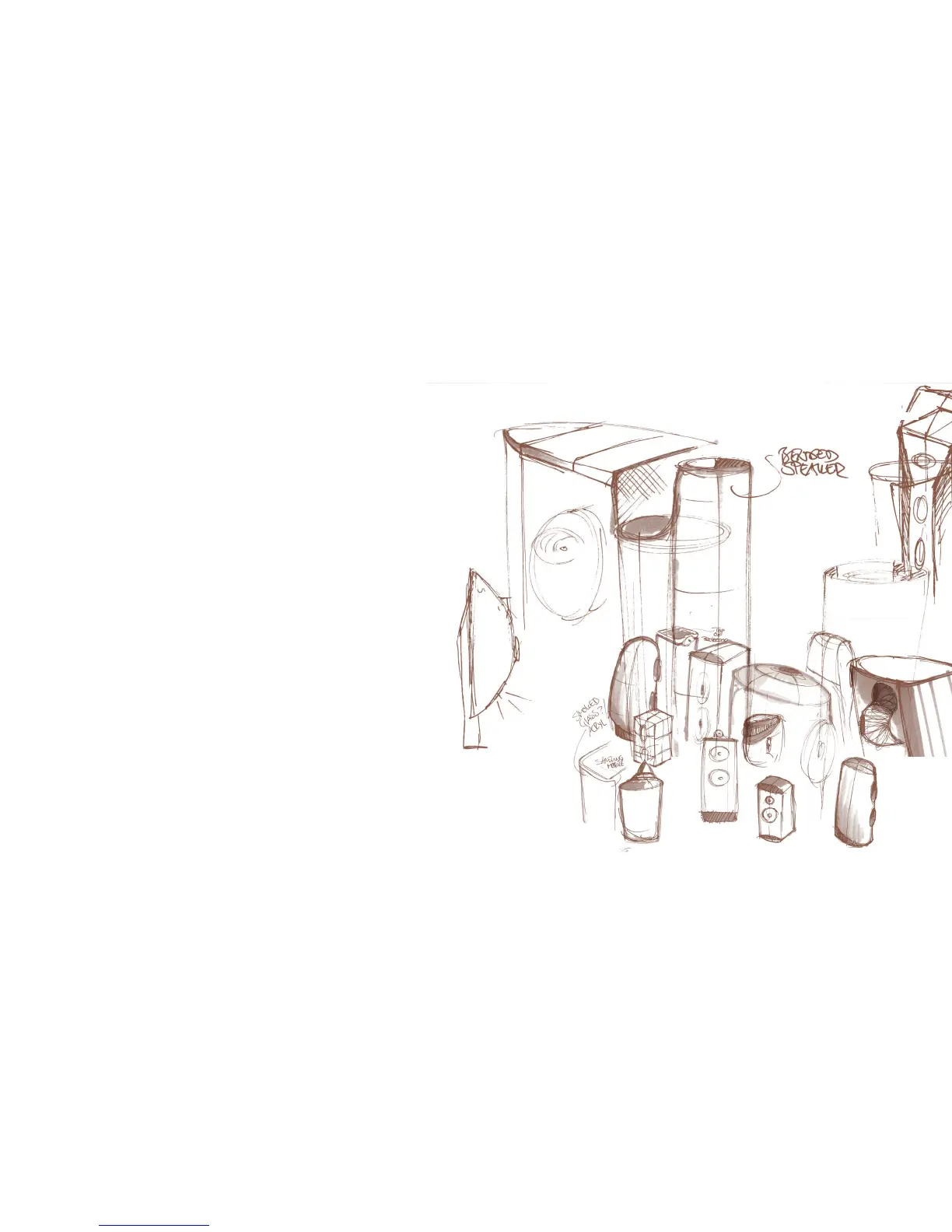

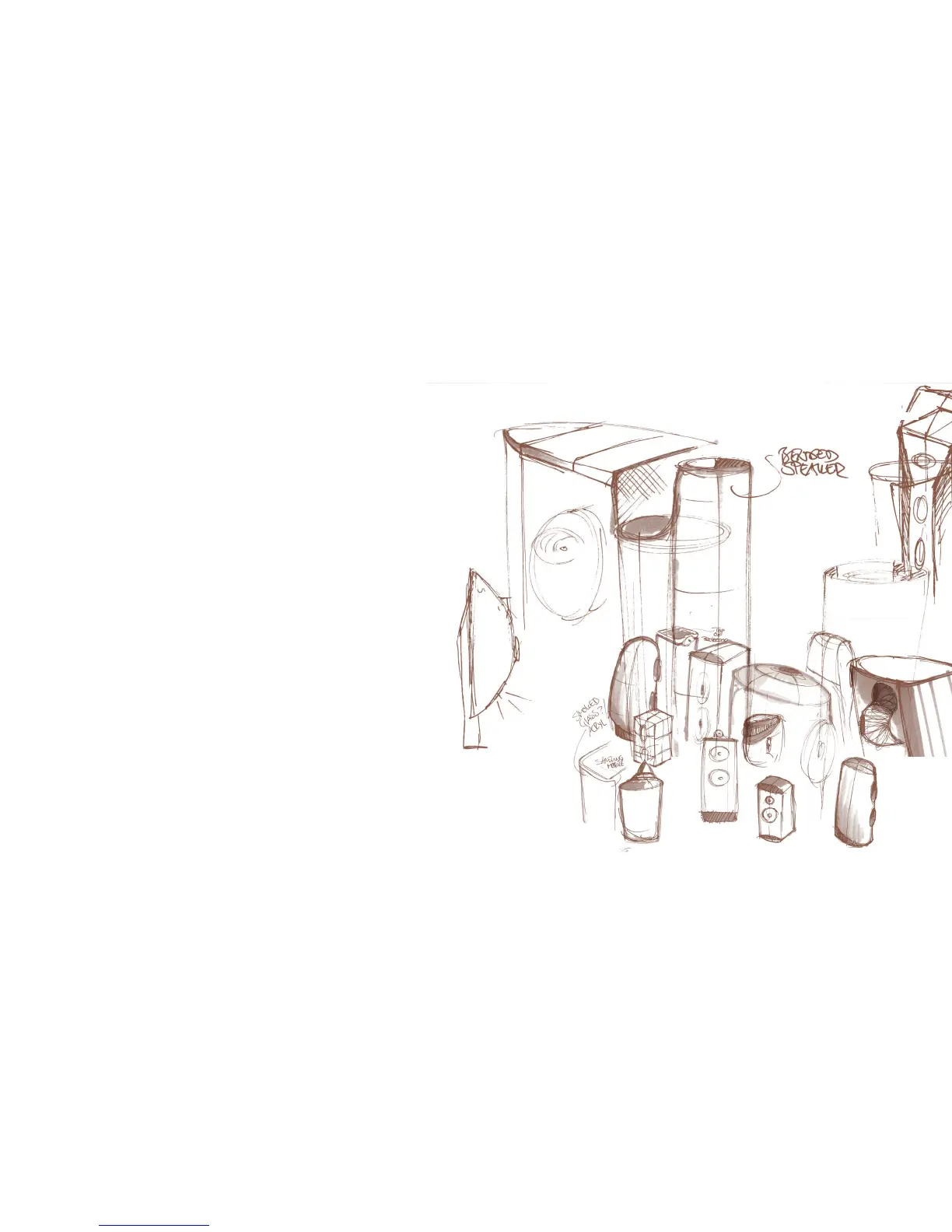

Then there’s the time when Malte Köhn,

Lead Product Designer on the Contour,

rocked up to a meeting with armfuls of

sketches (you can see some of them

here). “I tried to work with non-traditional

colour and material combinations,” he

says. “But I wanted to keep the Contour’s

classic design, which is quite edgy and

brutal. We turned it into something that’s

more elegant and technical.” Malte is

really proud of his design – and he should

be, because that’s the one we all chose

as a group.

Michael Rohde Böwadt, our brave VP of

product management, was the one who

took the leash off. “We went very wide

in the beginning,” he says. “I told them

to just make the best drivers in the

world. The best cabinets in the world.

To approach it all in a different way.”

No pressure, then.

“It backred a bit! But it was also very

interesting. We got some very interesting

results, provoked a lot of discussions,

and were able to really zero in on what

we wanted to do next.”

One of the things that came out of those

discussions was using different driver

materials. Ultimately we decided to stick

with our tried-and-true MSP – but we

told Daniel, Andreas and Danny that

we wanted it to sound even better. Their

Eureka! moment came when they started

varying the material’s thickness across the

Loading...

Loading...