providing a window into the process

How to Do It and Why?

I.V. has been used to determine

molecular weight relying on the key assumptions of

isolated flexible linear chains. You can eliminate the hindrances of the expertise, laboratory

and solvents required for solution measurements. Improvements in process control are

achievable using capillary rheometry methods over solution measurements due to their

simplicity and quick turnaround.

IV correlation calculations are only enabled when IV is set

to ACTIVE in the SETUP mode.

IV results are based on an empirical study that included various PET resins. A reference

material of known IV is needed to calibrate the melt indexer.

You must get an IV value for your material prior to testing.

Dry PET for 5 hours at 150 ºC, use 6 grams material per test, clean machine thoroughly

and run at a temperature of 285 ºC.

This option, if purchased, enables only at 285 ºC

1.) Clean the orifice, piston rod and barrel thoroughly. This is very important! Put piston rod

back into barrel until temperature has locked.

2.) Enable IV calculations under the Setup on the indexer. Note that a typical Pet test

temperature is to 285 ºC.

3.) Set the following parameters accordingly in EDIT mode:

Acceptable Methods: A, A/B, B

Melt time: 360 sec

Temperature: 285 C

Flag: 2.54 cm

Weight: 2160 kg

Note: Always perform a purge run of a new sample’

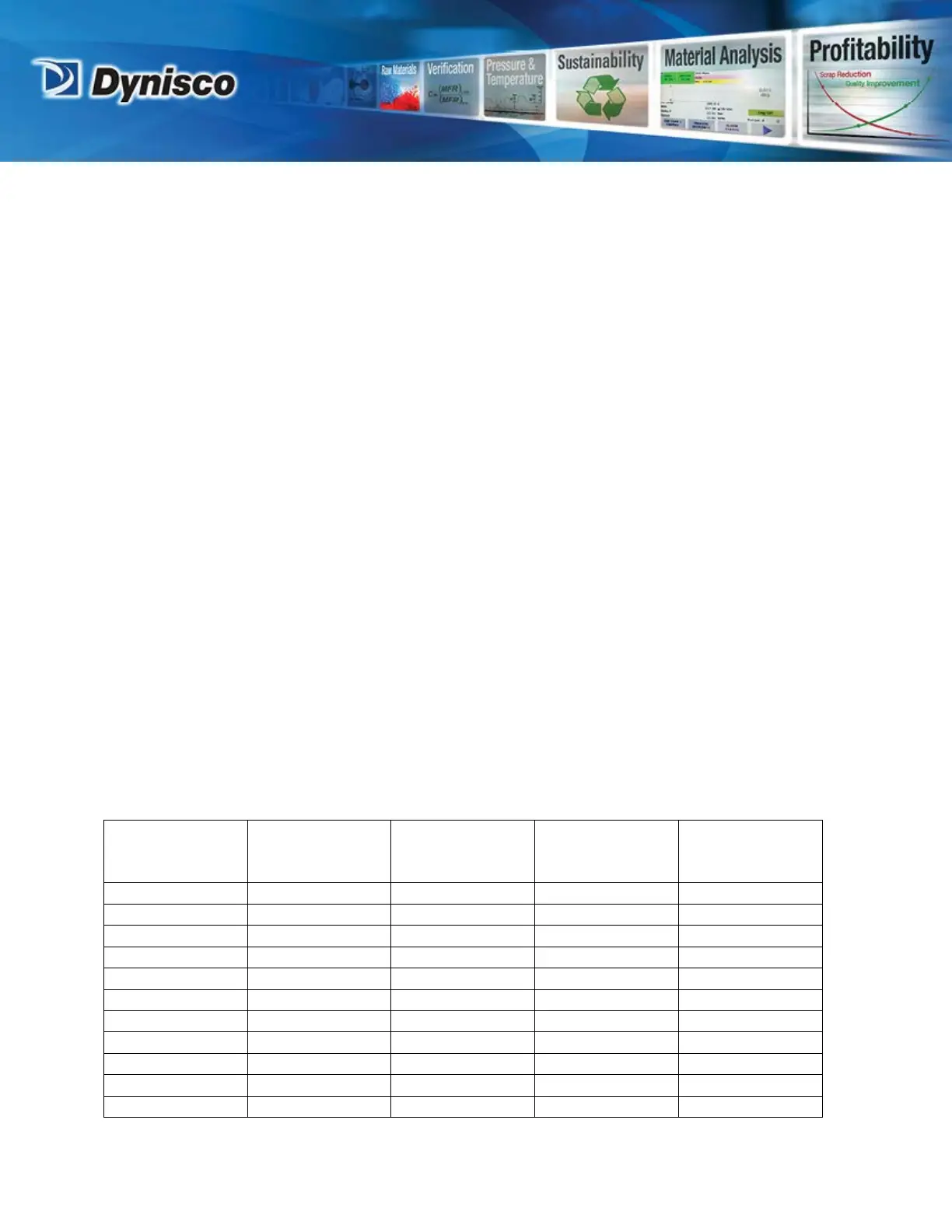

Example Settings/Procedures for known MFI’s

(cm)

Time

(seconds)

P/N: M0726(3) | Rev: 012020 | ECO: 51182

www.dynisco.com

Loading...

Loading...