- 10 -

4. Maintenance & Troubleshooting

4.7 Troubleshooting

Strap does not adhere properly

1. Improper temperature adjustment setting

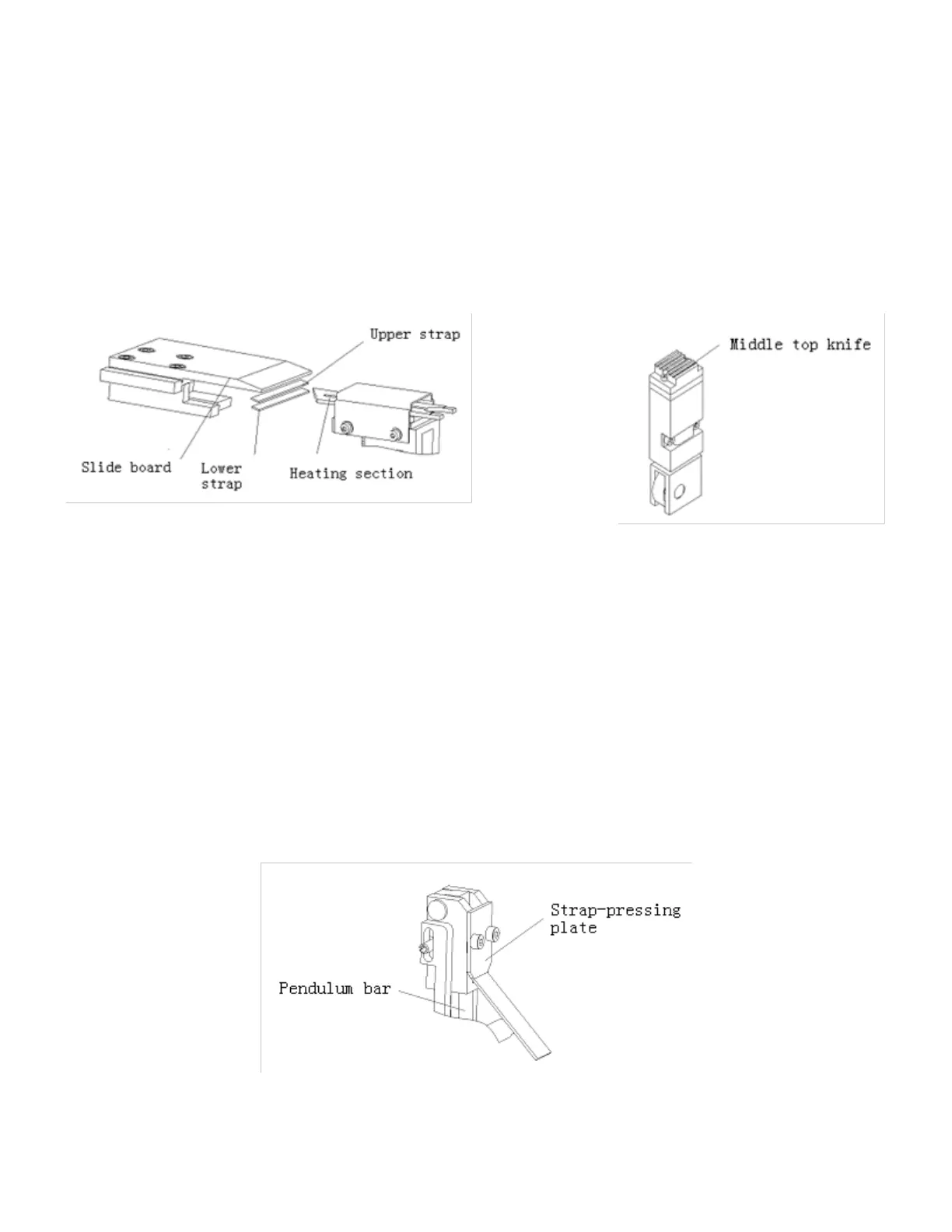

2. Deformation of the heating element (Fig. 4-5)

3. Split end on strapping

4. Insufficient pressure on middle top body, possibly cracked

5. Strapping material is too thin for use

Strap does not feed properly

1. The position of the crown bar is too high

a. If not on strap-withdrawing, the gap between crown and pry bar should be 0.3mm.

(Fig. 4-1)

2. Insufficient strap storage volume in strap collection bin.

a. Improper adjustment of pre-strap feeding mechanism

b. Pre-Strap feeding mechanism not drawing enough strapping material into collection bin

3. Strapping material end is split

a. If end is split, Pre-Strap feeding mechanism may not be able to draw in the strapping

material.

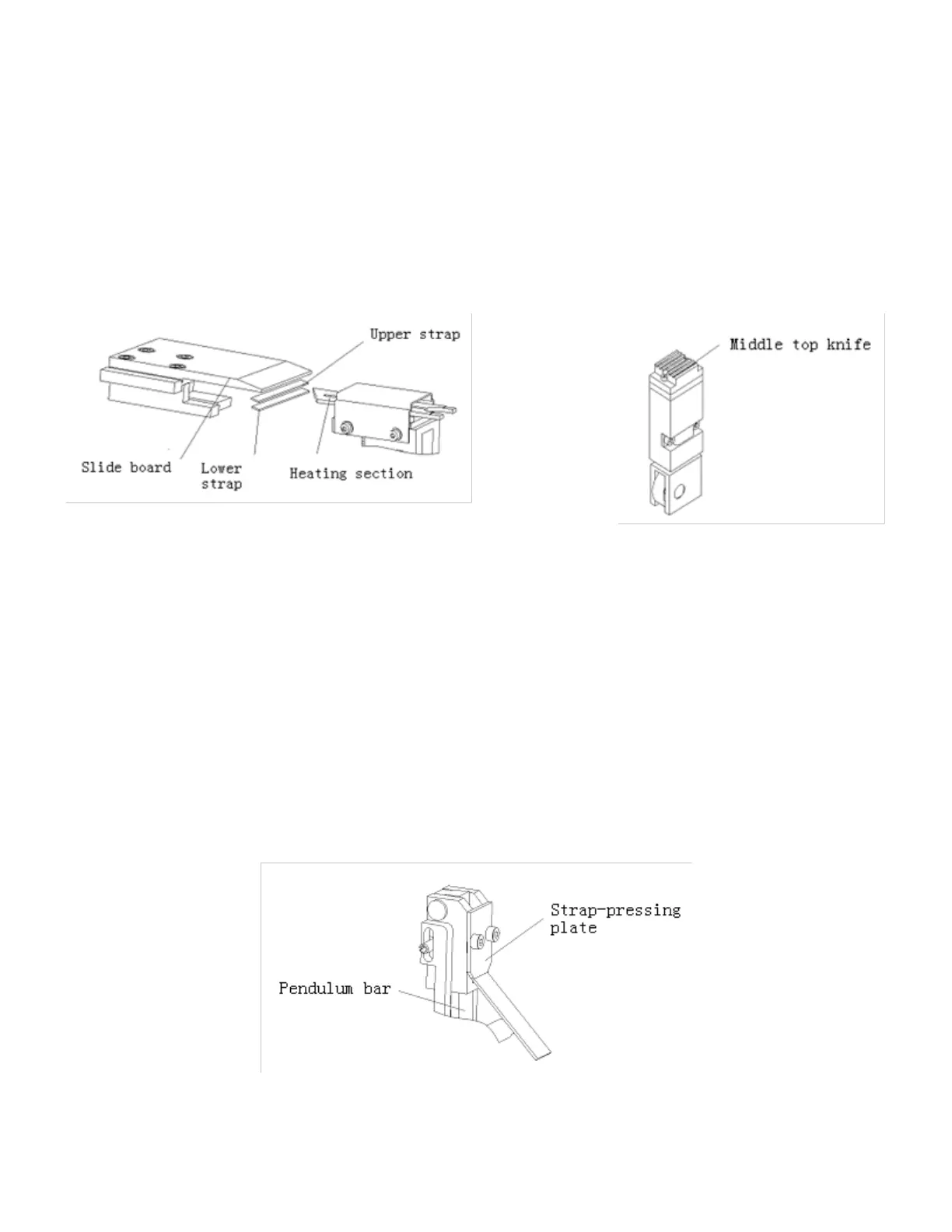

4. Strap press plate is too low (Fig. 4-7)

a. If adjusted such that that is minimal gap between the press plate and the swing link,

strapping material may not be able to pass through and into the machine.

Fig. 4-7

Loading...

Loading...