46

User Manual MN013016EN

Effective July 2022

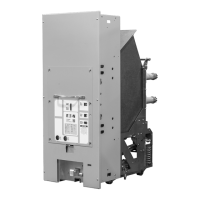

Magnum PXR and Power Defense SB low

voltage power circuit breakers user manual

EATON www.eaton.com

Maintenance schedule

Normal operating conditions

When determining how often a Magnum PXR and PD-SB breaker

should be inspected, the environmental and operating conditions

must be taken into consideration.

Table 11. Normal operating conditions

Normal operating conditions

Temperature Ambient temperature between 15 °C to 30 °C

(59 °F to 86 °F)

Percent load <80% of I

n

(sensor rating)

Relative humidity 40–70% in a noncondensing environment

Corrosive atmosphere Clean, dry, noncorrosive atmosphere

Salt environment No salt mist

Dust Protected by switchboard or switchgear assembly with

proper ventilation

Vibration Continuous vibration <0.2 g

Table 12 serves as a baseline for developing a maintenance

schedule. Under these conditions, the recommended maintenance

frequencies should be followed as written below.

Table 12. Normal maintenance frequency

Test/inspection Frequency

Arc chute inspection 1 year

Primary contact inspection 1 year or after a short circuit interruption

Internal mechanism inspection Every 250 operations or 3 years

Primary disconnect inspection

(drawout applications only)

Every time breaker is racked out

Secondary connection inspection Every time breaker is racked out

Interlocks inspection Every 250 operations or 3 years

Trip unit testing (primary injection) 5 years

Trip unit testing (secondary injection) 2–3 years

Adjusting maintenance frequency

Although Magnum PXR and PD-SB breakers are designed and

manufactured to operate in a wide variety of applications and

environments, there are some conditions that may require inspection

frequency to be increased.

Table 13. Increased frequency conditions

Factor Condition limits Recommended action

Operating conditions

High cycling Greater than one operation every 2 minutes Inspect every 1500 operations

Low cycling Less than one operation per year Double the normal inspection frequency

Repeated interruptions or overloads Three interruptions or 50 overloads (28 overloads for >2000 A breakers) Double the normal inspection frequency

Capacitive switching >135% of the capacitive bank load Double the normal inspection frequency

Environmental conditions

Temperature Ambient temperature is above or below 15 °C to 30 °C (59° F to 86° F) Double the normal inspection frequency

Temperature Breaker is placed in an area with a strong solar influence Double the normal inspection frequency

Dirt and contaminants Visible dirt or contaminants Remove contaminants from the breaker

and double the normal inspection frequency

Corrosive atmospheres Breaker is used in water or wastewater, pulp

and paper, petrochemical, or other harsh industrial atmospheres

Double the normal inspection frequency

Altitude >2000 m (6562 ft) Use appropriate voltage and current correction factors.

See Table 14 for rating factors. Short circuit current is not affect-

ed as long as the voltage is rated in accordance with the table.

Humidity Breaker is placed in a condensing environment Double the normal inspection frequency and inspect for rust

Use this table for ratings factor.

Table 14. Altitude rating factors

Altitude (meters) Voltage correction Current correction

2000 1.000 1.000

2100 0.989 0.998

2300 0.976 0.995

2450 0.963 0.993

2600 0.950 0.990

2750 0.933 0.987

2900 0.917 0.983

3050 0.900 0.980

3200 0.883 0.977

3350 0.867 0.973

3500 0.850 0.970

3650 0.833 0.967

3800 0.817 0.963

3950 0.800 0.960

5000 0.700 0.940

Loading...

Loading...