Do you have a question about the ebm-papst D3G280-GG10-01 and is the answer not in the manual?

Outlines operations and conditions that constitute improper use and are hazardous.

Lists key technical specifications, parameters, and performance data of the motor.

Highlights severe electrical shock hazards and precautions during connection.

Illustrates customer and internal wiring, detailing each terminal's function.

Provides step-by-step instructions for safely switching the device on and off.

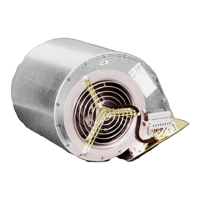

This document provides comprehensive operating instructions for an ebm-papst device, designed as a built-in component for air conveyance. It emphasizes safety, proper usage, and maintenance to ensure optimal performance and longevity.

The device is primarily an air conveying unit, intended for integration into larger systems. It operates within specific ambient air pressure ranges and is designed to handle air as the flow medium. The motor is equipped with integrated protective functions that automatically switch it off in the event of faults such as rotor position detection errors, blocked rotor, line undervoltage, or phase failure. These protective features ensure the safety of the device and the overall system. The motor is designed for continuous operation and includes thermal overload protection for both the electronics and the motor. It also features line undervoltage and phase failure detection.

The device incorporates a control input for speed adjustment, allowing for integration into various control systems. It provides a fixed voltage output for external devices, such as potentiometers, and includes an analog input for set value control. Communication with the device is possible via an RS485 interface, supporting MODBUS-RTU. A status relay provides feedback on the device's operational status, indicating failures. The motor is designed with maintenance-free ball bearings, lubricated for a long service life.

The device is intended for use in stationary systems and is compatible with various power systems, including grounded neutral (TN/TT), phase conductor grounding, and IT power systems, provided they meet EN 50160 network quality characteristics. It is crucial to operate the device with all protective devices in place and to follow the operating instructions diligently.

The device's installation position can be shaft horizontal or with the rotor at the bottom, with rotor-on-top configurations available upon request. Condensation drainage holes are located on the rotor side. The electrical connection requires careful attention to cable cross-sections, fuse ratings, and proper grounding. For installations with multiple devices, specific considerations for residual current devices (RCDs) are outlined, recommending AC/DC-sensitive types with delayed tripping.

The control input allows for flexible speed adjustment, either through a 0-10 V analog signal or PWM control, with factory settings configured for PWM control. The device's behavior in response to control signals can be set to positive (heating) direction of action. Cable routing is critical to prevent moisture ingress into the terminal box, with recommendations for U-shaped loops or drip edges.

Improper use, such as operating in an unbalanced state, with severe vibration, in medical life-support equipment, conveying solids or abrasive particles, painting the device, or operating with loose connections, is strictly prohibited to prevent hazards and damage. The device is not to be used in explosive atmospheres or as a safety component for safety-related functions.

Regular maintenance is essential for the device's long service life and includes periodic checks for proper operation and soiling. The frequency of these checks should be adjusted based on the degree of soiling in the operating environment.

Cleaning the device is a key maintenance task. It must only be performed when the fan is not in motion, and the power supply should be switched off via the control input to prevent accidental start-up. Dry cleaning, such as using compressed air, is the preferred method. Aggressive cleaning agents, water jets, high-pressure cleaners, acids, alkalis, solvents, or sharp objects must not be used, as they can damage the device. If cleaning does not resolve vibrations, rebalancing of the fan may be necessary.

A safety inspection should be conducted periodically, including visual checks of the contact protection cover, device for damage, cable fastenings, protective earth terminal, cable insulation, impeller for wear/deposits/corrosion, cable gland tightness, condensation drainage holes for clogging, and abnormal bearing noise. Any issues found should be addressed promptly, either by repair, replacement, or cleaning.

For devices not operated for extended periods, especially in dry environments, it is recommended to start them up and operate at full speed for one hour every four months. In damp environments, this should be done for at least two hours once a month to move the bearings and evaporate any condensate. The device is designed with maintenance-free ball bearings, but if replacement becomes necessary after their expected service life, ebm-papst should be contacted.

Disassembly and disposal of the product must be carried out by qualified personnel, adhering to country-specific legal regulations and environmental protection guidelines. The product components, primarily steel, copper, aluminum, and plastic, are largely recyclable and should be separated into appropriate categories for recycling. Electronic components should be disposed of according to proper electronic scrap procedures.

| Manufacturer | ebm-papst |

|---|---|

| Model | D3G280-GG10-01 |

| Category | Fan |

| Type | AC Fan |

| Nominal Voltage | 230 V |

| AC Fan Supply Voltage | 230 V |

| Bearing Type | Ball Bearing |

| Fan Material | Plastic |

| Impeller Material | Plastic |

| Kind of Protection | IP54 |

| Protection Class | I |

| Connection | Terminal box |

| Operating Temperature | -20 °C to +60 °C |

| Motor Type | AC |

Loading...

Loading...