Do you have a question about the ebm-papst M4Q045-CF07-04 and is the answer not in the manual?

Defines hazard symbols (DANGER, WARNING, CAUTION) and their meanings.

Specifies required qualifications for installation, operation, and maintenance personnel.

Outlines general safety guidelines and best practices for working with the device.

Highlights electrical shock risks associated with voltage and proper precautions.

Warns about entanglement risks and ejected parts from rotating components.

Details specific operating conditions that are hazardous and prohibited.

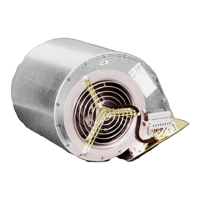

This document describes the M4Q045-CF07-04 motor, an ebm-papst product designed exclusively for use as a drive motor. It emphasizes safety, proper installation, and maintenance to ensure reliable operation and a long service life.

The M4Q045-CF07-04 is a drive motor intended for various applications where a reliable rotating force is required. Its design allows for continuous operation (S1 mode) and is equipped with an internal thermal overload protector (TOP) for enhanced safety. The motor's rotation direction is counterclockwise when viewed toward the shaft end.

General Data:

Nominal Data (for 50 Hz operation):

Nominal Data (for 60 Hz operation):

Transport and Storage Conditions:

Mounting Data:

The M4Q045-CF07-04 is designed for operation within specified ambient temperature ranges and with all protective devices in place. It is crucial to follow the operating instructions to ensure safe and proper functioning.

Intended Use:

Prohibited and Hazardous Improper Use:

Electrical Connection:

Mechanical Connection:

Regular maintenance and safety inspections are crucial for the device's longevity and safe operation.

Cleaning:

Safety Inspection (every 6 months):

Storage:

Troubleshooting (Malfunctions, Possible Causes, and Remedies):

General Maintenance Notes:

Disposal:

Loading...

Loading...