10

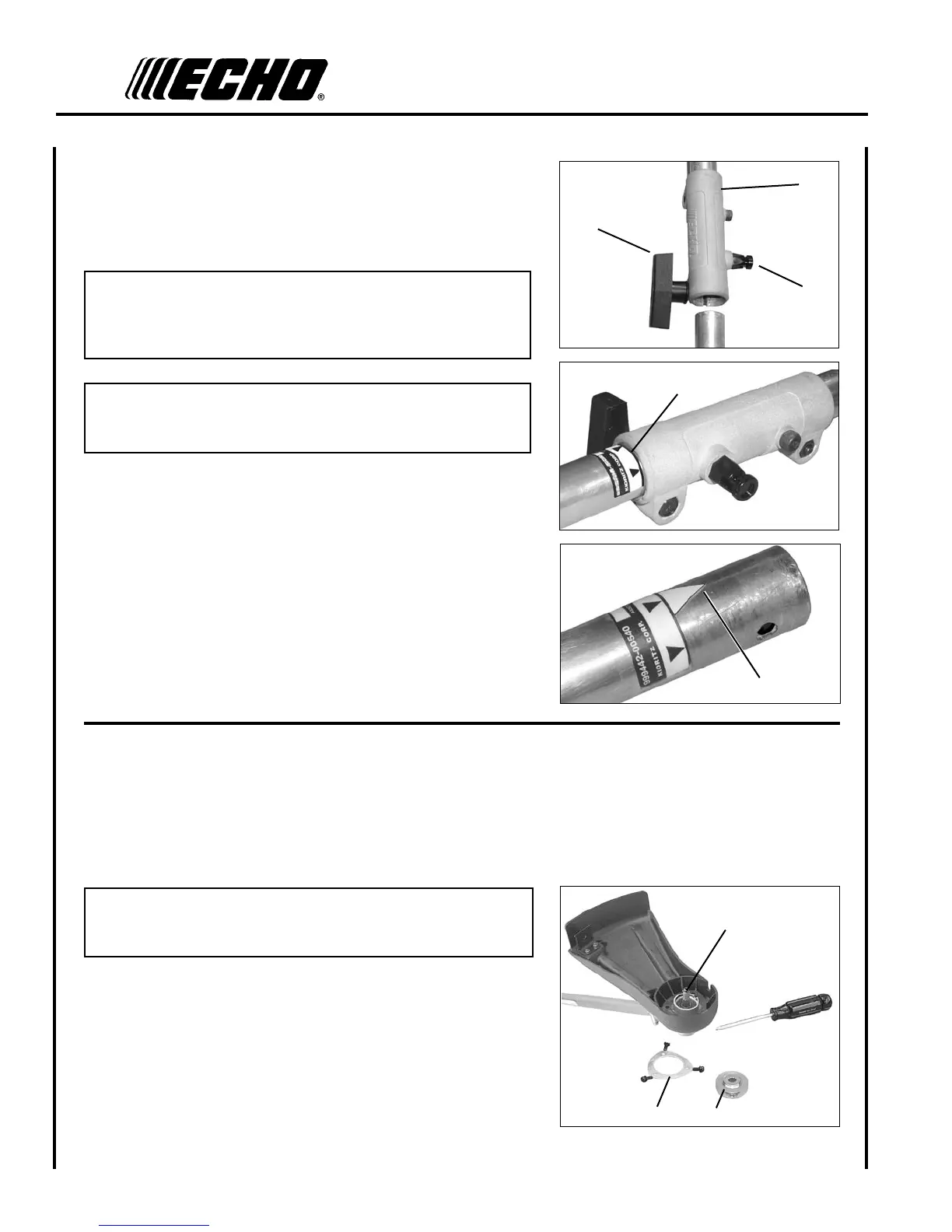

D

A

C

B

E

5. Carefully t attachment drive shaft assembly into coupler (B) to

decal assembly line (C), making sure that the inner lower drive shaft

engages the square upper drive shaft socket.

NOTE

Earlier model Power Heads may have shorter couplings. Short

couplings t ush to decal point (E). New couplings are 4-3/4 in.

long, and t ush to line (C).

NOTE

Lower bearing housing and head assembly must be in line with the

engine.

6. Rotate locator pin (A) 1/4 turn clockwise to engage lower shaft

hole. Insure locator pin is fully engaged by twisting lower drive

shaft. Locator pin should snap ush in coupler. Full engagement

will prevent further shaft rotation.

7. Secure lower shaft assembly to coupler by tightening clamping

knob (D).

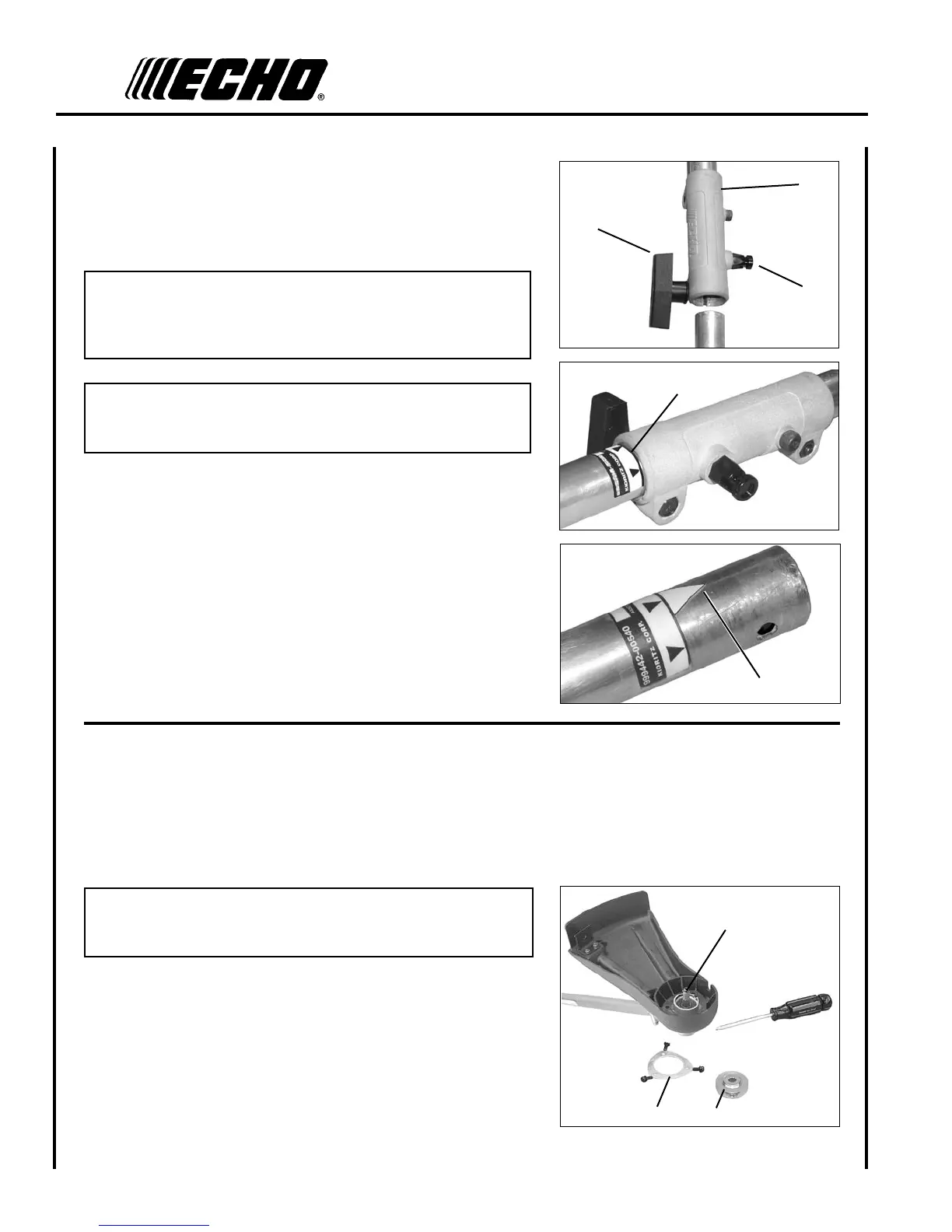

p l a s t I c s h I e l d I n s t a l l a t I o n

(for Nylon Line Operation)

Tools Required: Torx T27 L-Wrench

Parts Required: Plastic Shield, Shield Plate, three (3) 5mm x 16mm

screws.

NOTE

The plastic shield is for use with the Nylon Line Head only.

Install Metal Shield when using plastic or metal blades.

1. Remove plastic threaded shaft sleeve and adapter plate (C) from

PTO shaft (A).

2. Place the shield on the bottom of the bearing housing ange.

3. Place shield plate (B) on shield, align holes. Install three (3) screws

from bottom through plate and shield into gear case.

4. Assemble adapter plate (C) onto PTO shaft.

A

B

C

Loading...

Loading...