16

Eclipse RatioMatic Burners, RM Series, V5, Installation Guide 110, 12/3/2014

5. Close internal bypass adjusting screw by turning it

clockwise to closed position.

6. Set system control to stay at low fire during and after

ignition sequence.

7. Attempt to ignite burner.

8. If burner does not ignite:

a. Attempt to ignite burner again to purge air from the

gas piping.

b. If burner still does not ignite, turn bias adjusting

screw a half turn clockwise to increase gas flow.

c. Attempt to ignite burner.

d. Repeat steps b and c until burner ignites. If

necessary, refer to Chapter 5 for troubleshooting

tips.

9. After burner ignites, slowly decrease gas flow with

bias adjusting screw . Decrease gas flow until the

flame signal becomes erratic. (Refer to flame

monitoring relay literature for a description of an

erratic flame signal.)

10. If burner has gone out: Repeat ignition sequence.

Turn internal bypass adjusting screw a half turn

counterclockwise to increase gas flow at each attempt

until burner lights.

11. Flame signal strength: Adjust gas flow with internal

bypass adjusting screw for lowest gas flow that

maintains a stable flame signal:

• clockwise, for more fuel

• counterclockwise, for less fuel

12. Verify low fire flame:

a. Shut off gas. When chamber temperature is below

250°F (121°C), shut off combustion air blower.

b. Restart combustion air blower and ignite burner.

c. Verify repeatability of ignition and low fire flame

signal.

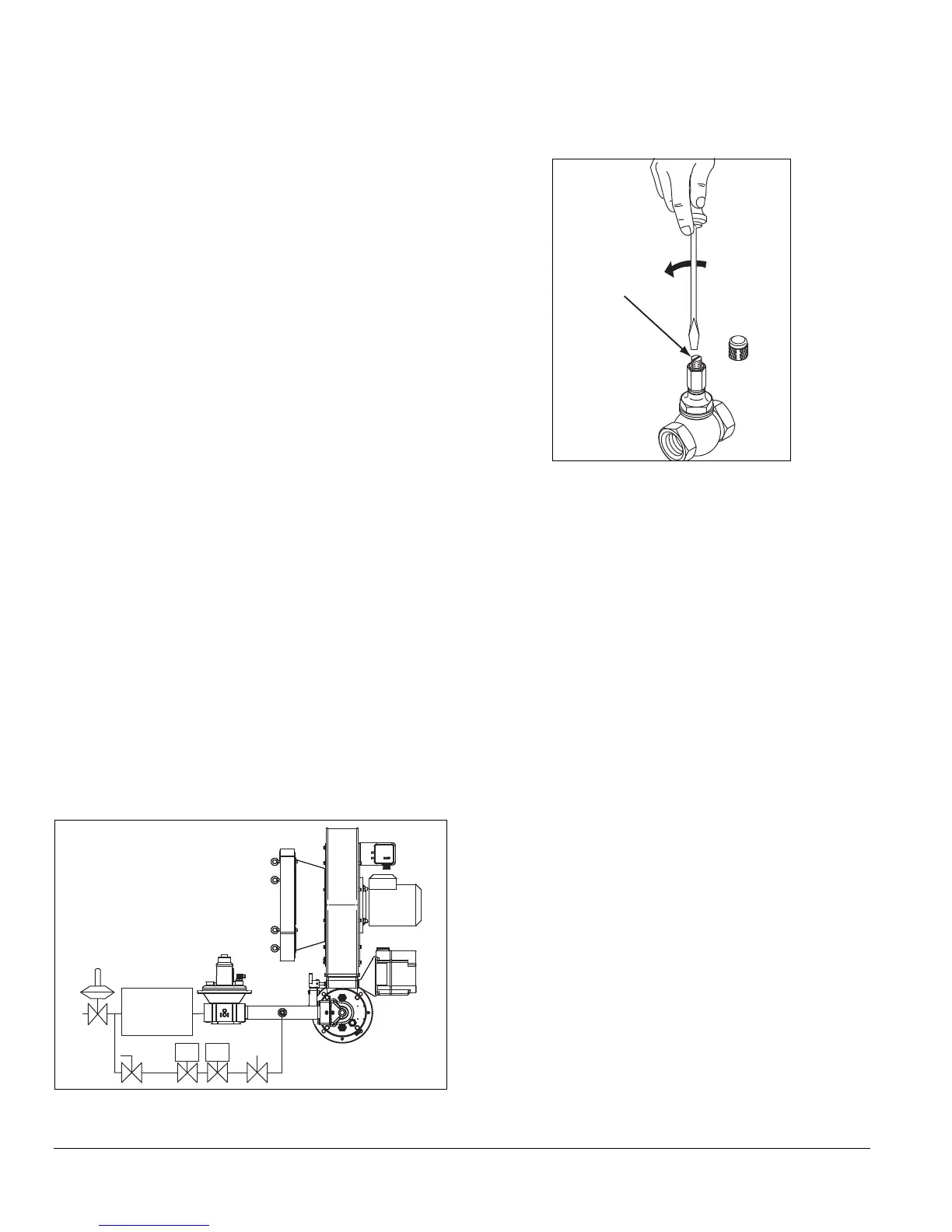

Procedure C: Bypass start gas without fuel orifice

meter

Figure 4.11. Procedure C

1. Drive control motor to low fire.

2. Be sure combustion air blower is running.

3. Be sure main gas manual shut off valves are closed.

4. Open main gas manual shut off valve in the bypass.

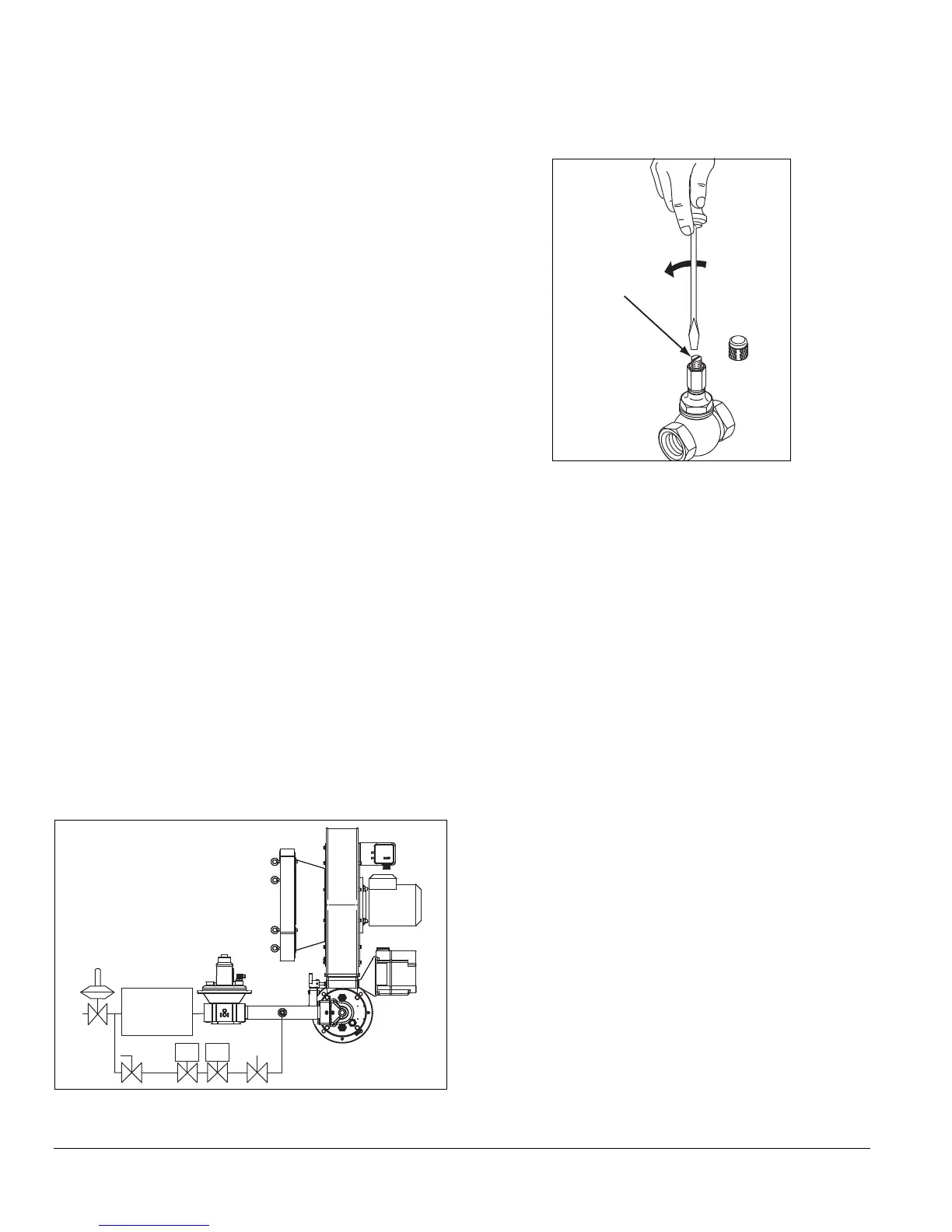

Figure 4.12. Adjusting Limiting Orifice (ALO)

5. Set the system to operate on bypass gas only.

6. Attempt to ignite burner by energizing spark and

bypass gas solenoid valves .

7. If burner does not ignite:

a. Attempt to ignite burner again to purge air from the

gas piping.

b. If burner still does not ignite, turn ALO adjusting

screw a half turn counterclockwise to increase

gas flow.

c. Attempt to ignite burner.

d. Repeat steps b and c until burner ignites. If

necessary, refer to Chapter 5 for troubleshooting

tips.

8. Flame signal strength: Adjust gas flow ALO adjusting

screw for lowest gas flow that maintains a stable

flame signal:

• counterclockwise, for more fuel

• clockwise, for less fuel

9. Verify low fire flame:

a. Shut off gas. When chamber temperature is below

250°F (121°C), shut off combustion air blower.

b. Restart combustion air blower and ignite burner.

c. Verify repeatability of ignition and low fire flame

signal.

Main gas

shut-o

valve train

NC

NC

CCW for

more gas

Cap

ALO

djusting

Screw

Loading...

Loading...