6

To remove the tube from this type of fitting, first pull or push

the gray collar towards the fitting body, then pull out the

tube.

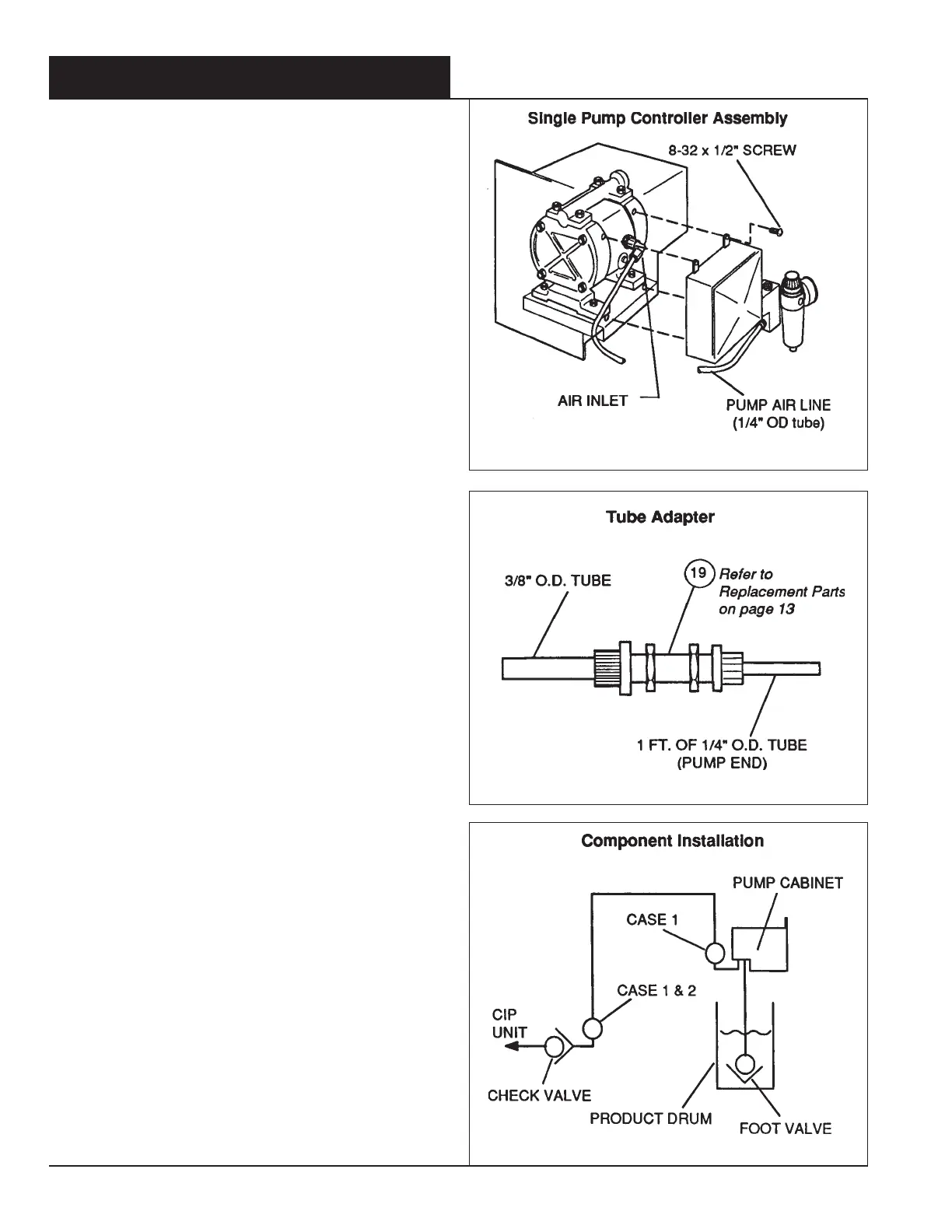

4.3 Pump Shelf with Pump

1. The shelf may be directly mounted on a wall using the

supplied wall mount anchors and screws. For multiple

pump mountings, the Multiple Pump Mounting Bracket

may be used.

Refer to Section 3, page 4

.

2. Mount the shelf so the pump inlet is a maximum of 3-1/2

ft. (107 cm) above the drums lowest possible liquid level

and 10 ft. (3 meters) maximum horizontal. Always locate

the pump above the product drum.

3. Take the free end of the "Pump Air Line" coming from the

pneumatic cabinet and insert it approximately 1/2 inch into

the fitting on the side of the pump. It will be automatically

retained. Make a reference mark 1/2" from the tube and

prior to the insertion

To remove the tube from this type of fitting, first pull or push

the gray collar towards the fitting body, then pull out the

tube

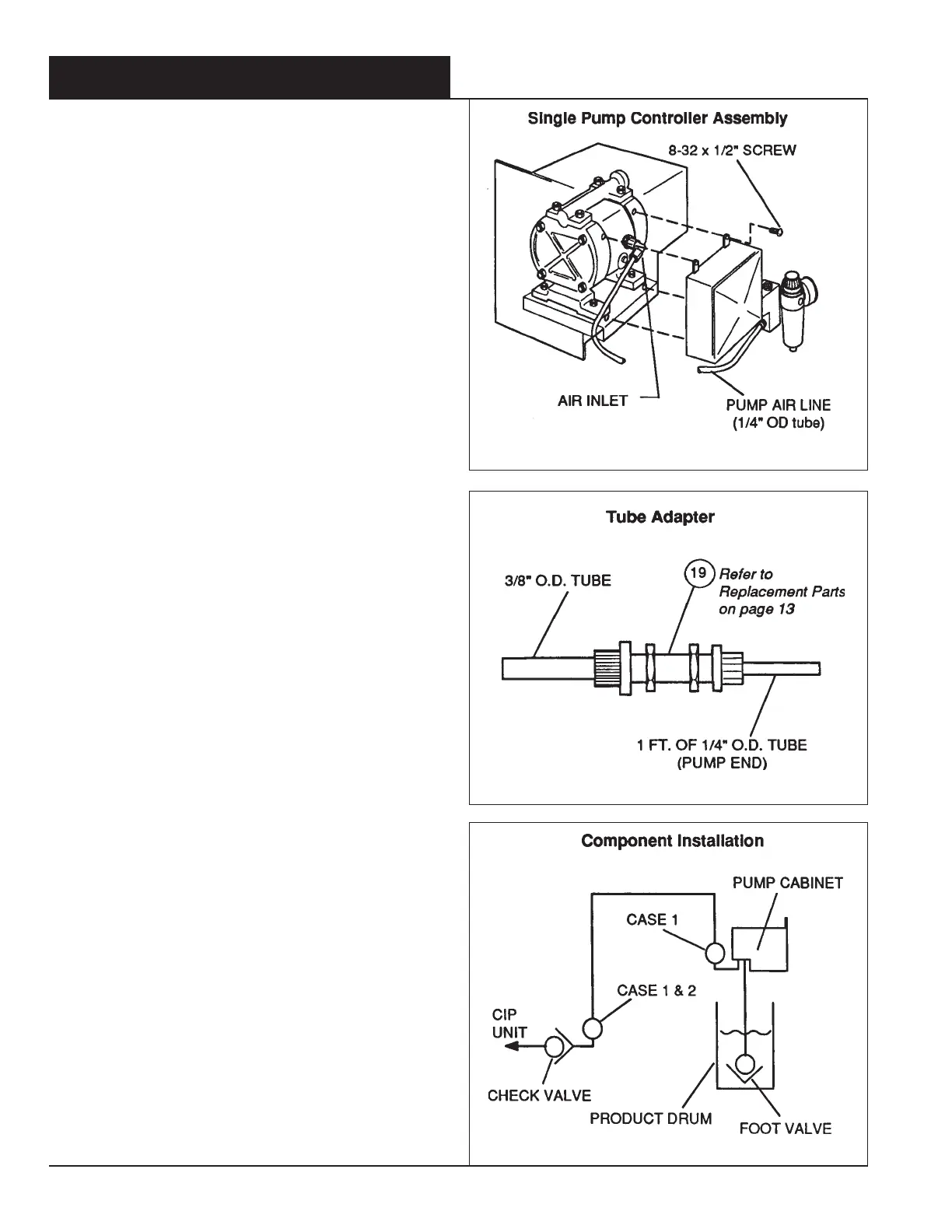

4. If a 3/8" OD pump air line is required (

See Section 4.1 #2

on page 5

), it may be adapted to the pump fitting as

illustrated.

Refer to Figure 9.

5. For product lines, use 19/32" OD x 3/8 ID EVA reinforced

tubing for the discharge line. Install this line to the top

pump port.

6. Install 1/2" OD x 3/8" ID polyethylene or EVA (unreinforced)

tubing for the intake line. The unreinforced EVA tubing is

preferred because of its flexibility. Install this line to the

bottom pump port.

7. Install on the intake line a foot valve.

Refer to Section 4.5

below.

4.4 Anti-Siphon Valve

Install the anti-siphon valve according to the direction of the

specific installation case. Match anti-siphon valve to product

being dispensed. See replacement parts.

CASE 1 - (injecting into the suction side of the CIP pump and

when the chemical feed pump is above injection point).

1. Place an anti-siphon valve within 2 ft of the chemical feed

pump in its discharge line. Also install a second anti-

siphon valve ahead of the check valve at the injection

point. Condition of this case is based on the pump being

above the product tank.

Refer to Figure 10.

CASE 2 - (Injecting into the suction side of the CIP pump and

when the chemical feed pump is below injection point).

1. Place an anti-siphon valve ahead of the check valve at the

injection point.

Refer to Figure 10.

4.5 Ball Foot Valve

1. The ball foot valve is used along with the drum probe.

4.0 INSTALLATION PROCEDURES (con't)

Figure 8

Figure 9

Figure 10

Loading...

Loading...