11

11. Begin assembling the discharge side by installing the

valve seat. Squarely locate the valve onto the seat. While

keeping the valve centered install the valve guide. Install

the o-ring, manifold and secure with washers and nuts.

12. Tighten nuts to 35 to 45 in-lbs.

10.0 INSTALLATION OPTIONS

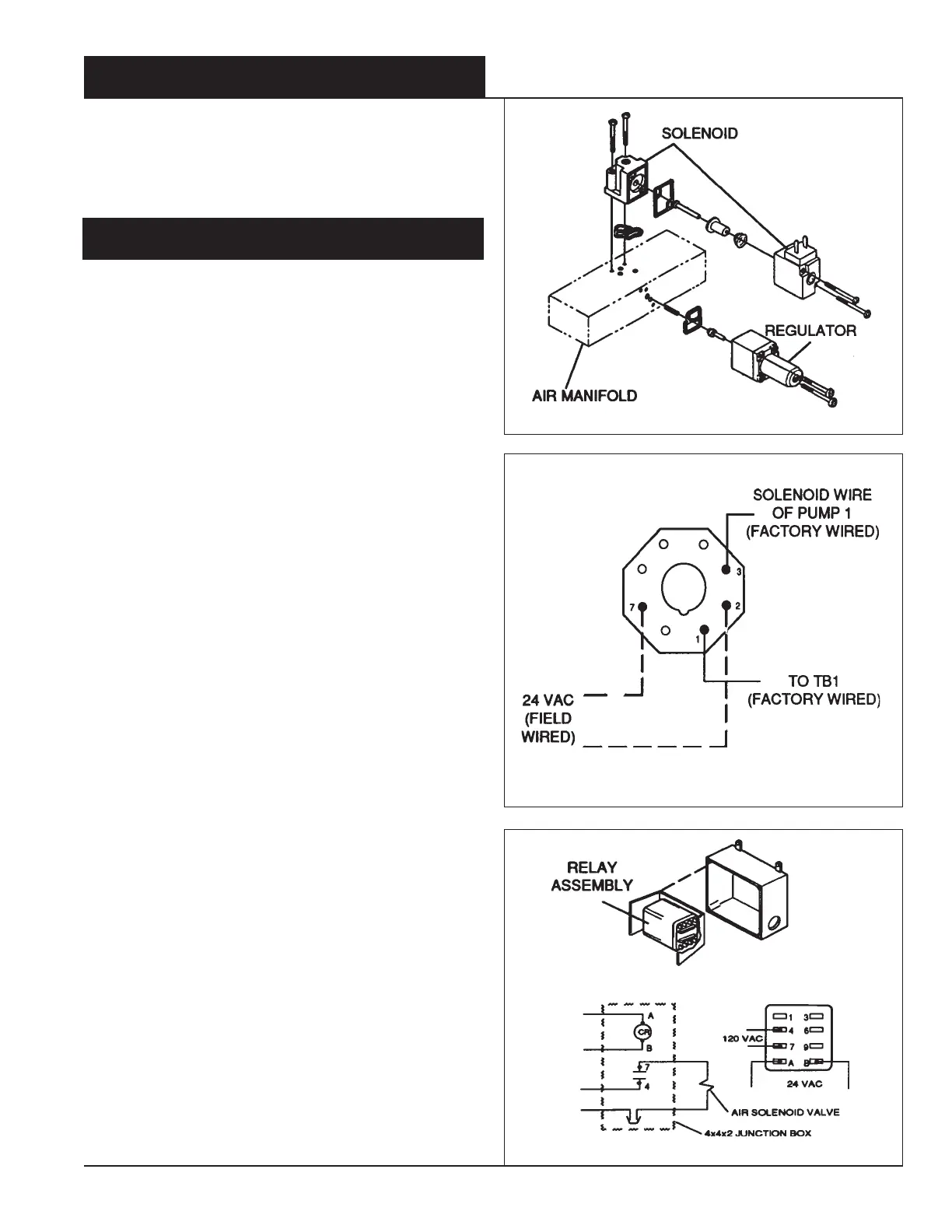

10.1 Adding a Solenoid and Regulator

1. Remove the ty-wraps that are supporting the solenoid

leads inside the control cabinet.

2. Remove the (10) screws on the exterior right side of the

control cabinet that are holding the air manifold mounting

panel to the cabinet. With the manifold attached to the

panel, pull the panel away from the cabinet.

3. To allow mounting a solenoid and regulator, remove the

port covers from the next available manifold station.

4. Mount the solenoid and regulator as shown in

Figure 15

.

Secure their mounting screws firmly.

5. Remount the manifold panel.

6. Attach the solenoid leads to the next available position on

the terminal block.

7. Attach the ty-wrap mount in the cabinet.

8. Individually bundle the solenoid leads and secure them to

a mount with a ty-wrap.

9. Install the pressure gauge by inserting the gauge tube

end, about 1/2 inch, into the mating part on the solenoid

valve.

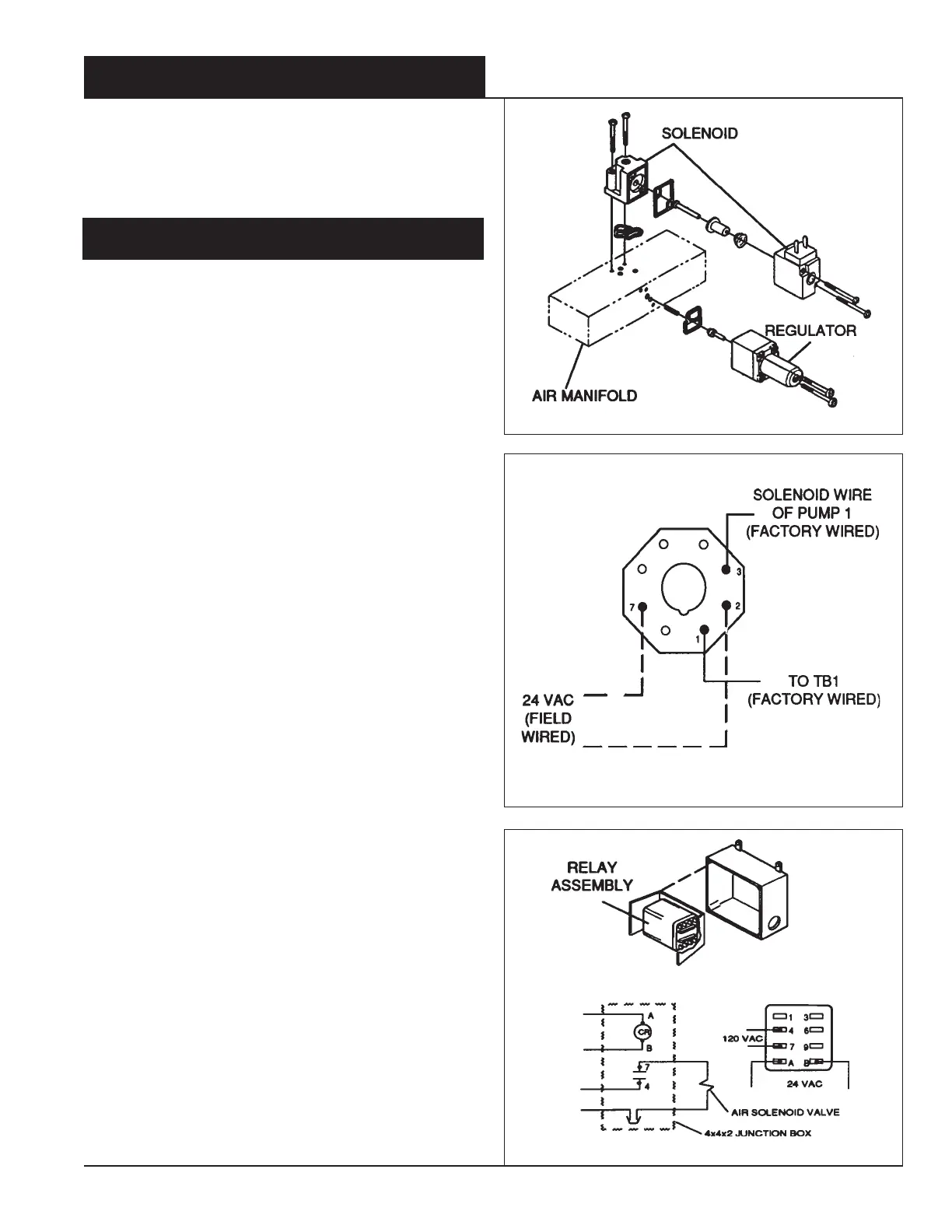

10.2 S-2000 for Multiple Pump Controller

1. Signal wires from the S-2000 should be connected to

terminals 2 and 7 of the octal socket. Remove from the

socket the purple jumper wire between 1 and 3. Install into

the socket the 24 VAC relay (item 7 "Replacement Parts"

page 13). This will control "Pump 1".

Refer to Figure 16

.

10.3 S-2000 for Single Pump Controller

1. If a 24 VAC signal is used, make an additional hole in the

junction box (7/8 diameter is required for 1/2 electrical

conduit) for the 24 VAC signal. Use the special 24 VAC

relay assembly, (Item 12, "Replacement Parts" on page

13). Slide this assembly into the junction box. R

efer to

Figure 17.

9.0 PUMP SERVICING (con't.)

Figure 15

Figure 16

Figure 17

Loading...

Loading...