8

6.1 Multiple Pump Pneumatic Controller

1. Check that all pump control regulator adjustment knobs

are in the full counter-clockwise position.

2. Check that the pump intake probes are in the appropriate

products.

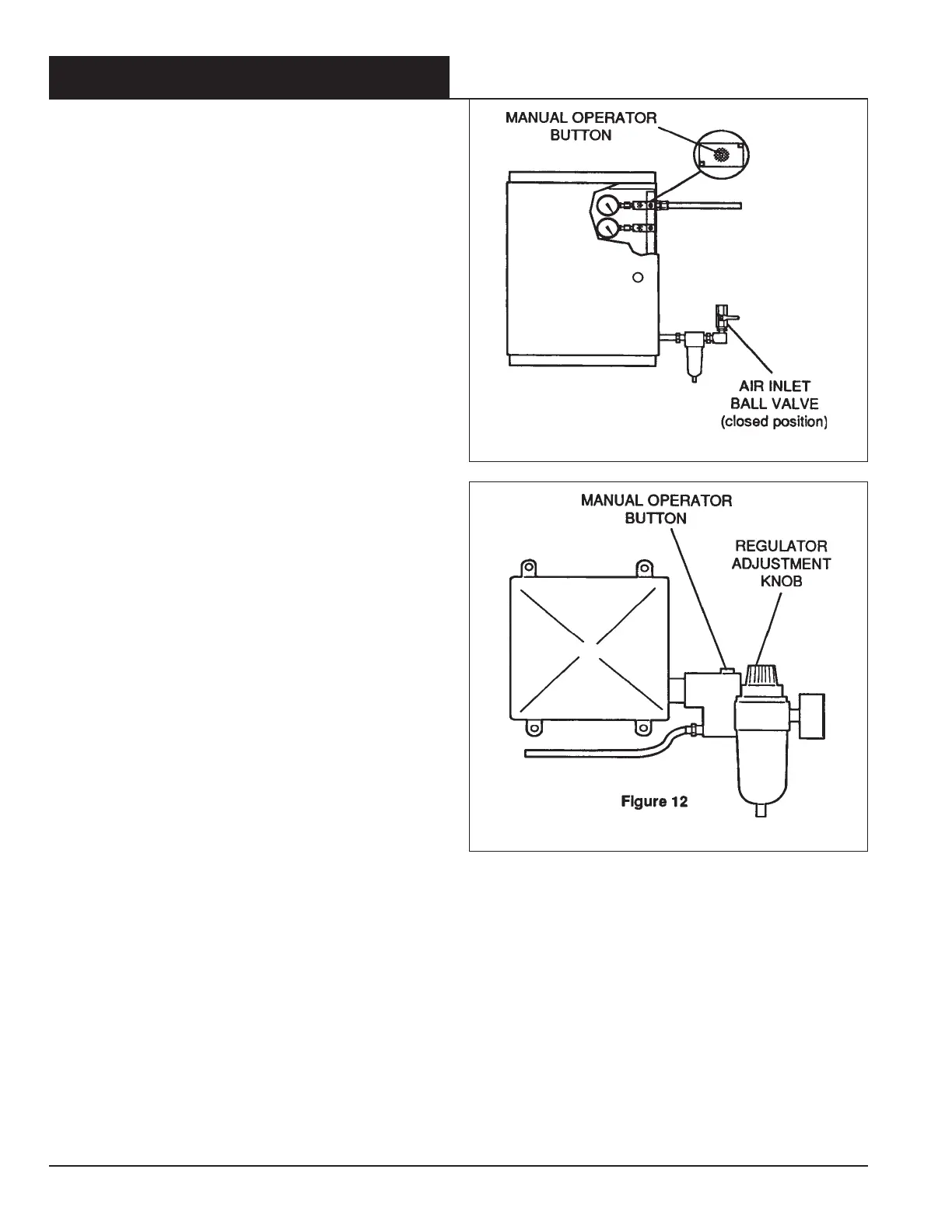

3. Open the air inlet ball valve.

Refer to Figure 11.

4. While pressing the manual operator button on the sole-

noid valve with a "pen tip", rotate the regulator adjustment

knob until the pump starts (approximately 18 psig or 1.2

bars)

5. Continue to increase the air pressure to establish the

pressure needed for the required flow rate.

Refer to the

graphs in Section 11, page 12

to use as a set-up guide line

to determine this approximate air pressure.

6. Fine tune the delivery by taking a solution sample and

titrate it.

7.

Refer to paragraph "6.3 Pump"

below for additional pump

delivery information when less than 20 oz./min.

6.0 OPERATIONS

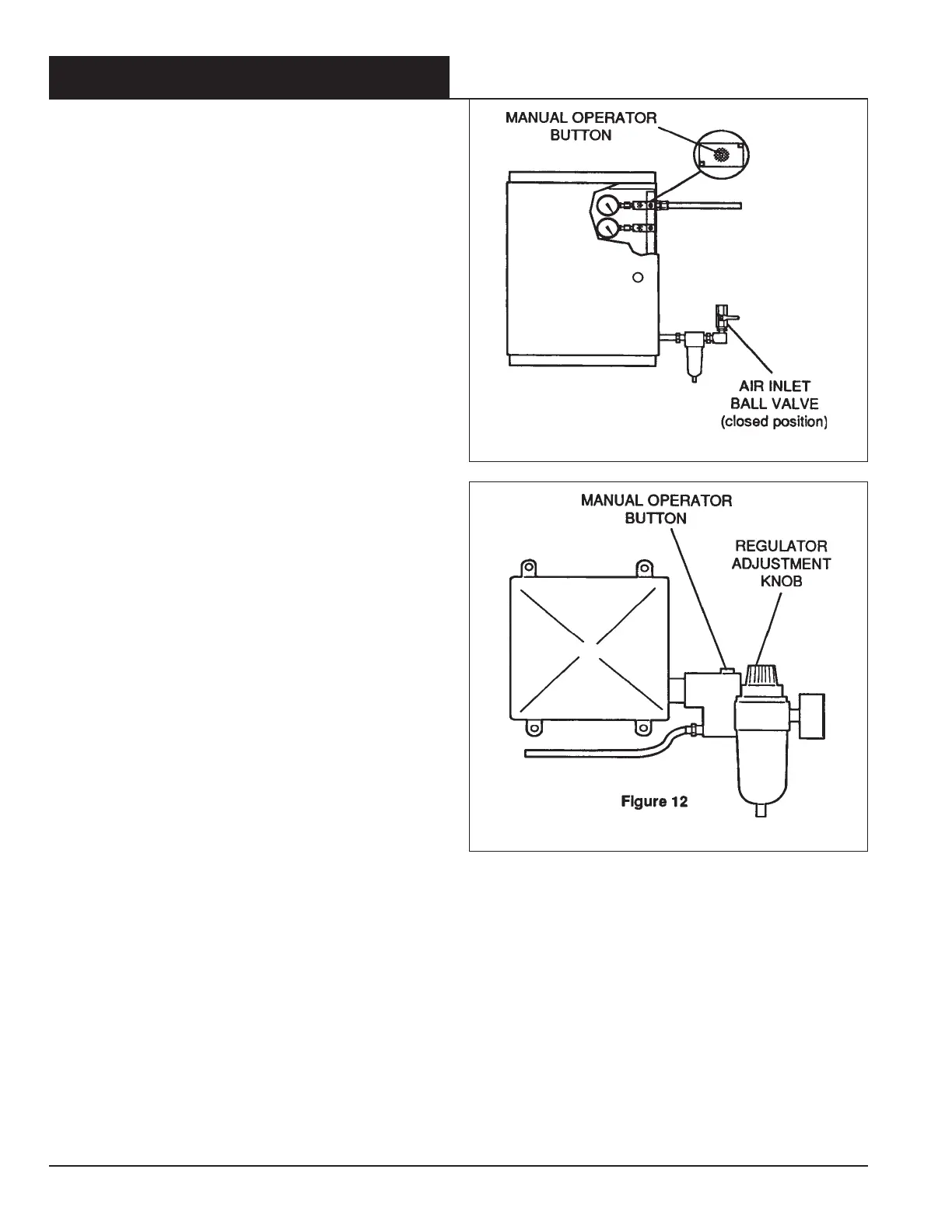

6.2 Single Pump Pneumatic Controller

1. Check that the regulator control knob is in the full counter-

clockwise position.

2. Check that the pump intake probe is in the product.

3. Open the air inlet ball valve.

4. While pressing the manual operator button on the sole-

noid valve with a "pen tip", rotate the regulator adjustment

knob until the pumps starts (approximately 18 psig or 1.2

bars).

Refer to Figure 12.

5. Continue to increase the air pressure to establish the

pressure needed for the required flow rate.

Refer to

graphs in Section 11, page 1

2 to determine this approxi-

mate air pressure.

6. Fine tune the delivery by taking a solution sample and

titrate it.

7.

Refer to paragraph "6.3 Pump"

below for additional pump

delivery information when less than 20 oz./min.

6.3 Pump

Flow rate is primarily regulated by controlling the pump air

pressure. An air pressure of at least 20 psig (1.4 bars) (for

water) is required to have the pump operate.

Alternatively the flow rate may be regulated by the discharge

pressure. It may become necessary to control the delivery by

using a needle valve or orifice in the discharge line to increase

the discharge pressure when the required pump operating air

pressure is at the minimum and the flow rate must be further

reduced. Referencing the performance curves in

Section 11,

page 12

, you will see for a given air pressure how the flow rate

decreases as the discharge pressure increases. An example

of when a needle valve or orifice will help to increase the

discharge pressure is for tank top feeding. The orifice should

be used rather then the needle valve when flow rates less than

20 oz./min. (590 cc/min.) are needed.

Refer to Section 11,

page 12 - Table 1

for Orifice options.

1. Place the orifice assembly in the discharge line.

2. Fine tune the delivery by taking a solution sample and

titrate it.

Figure 11

Figure 12

Loading...

Loading...