I

,

,t_

L

X[I. TROUBLESHOOTING

GUIDE

FOR

LOCKOUT

CONDITIONS

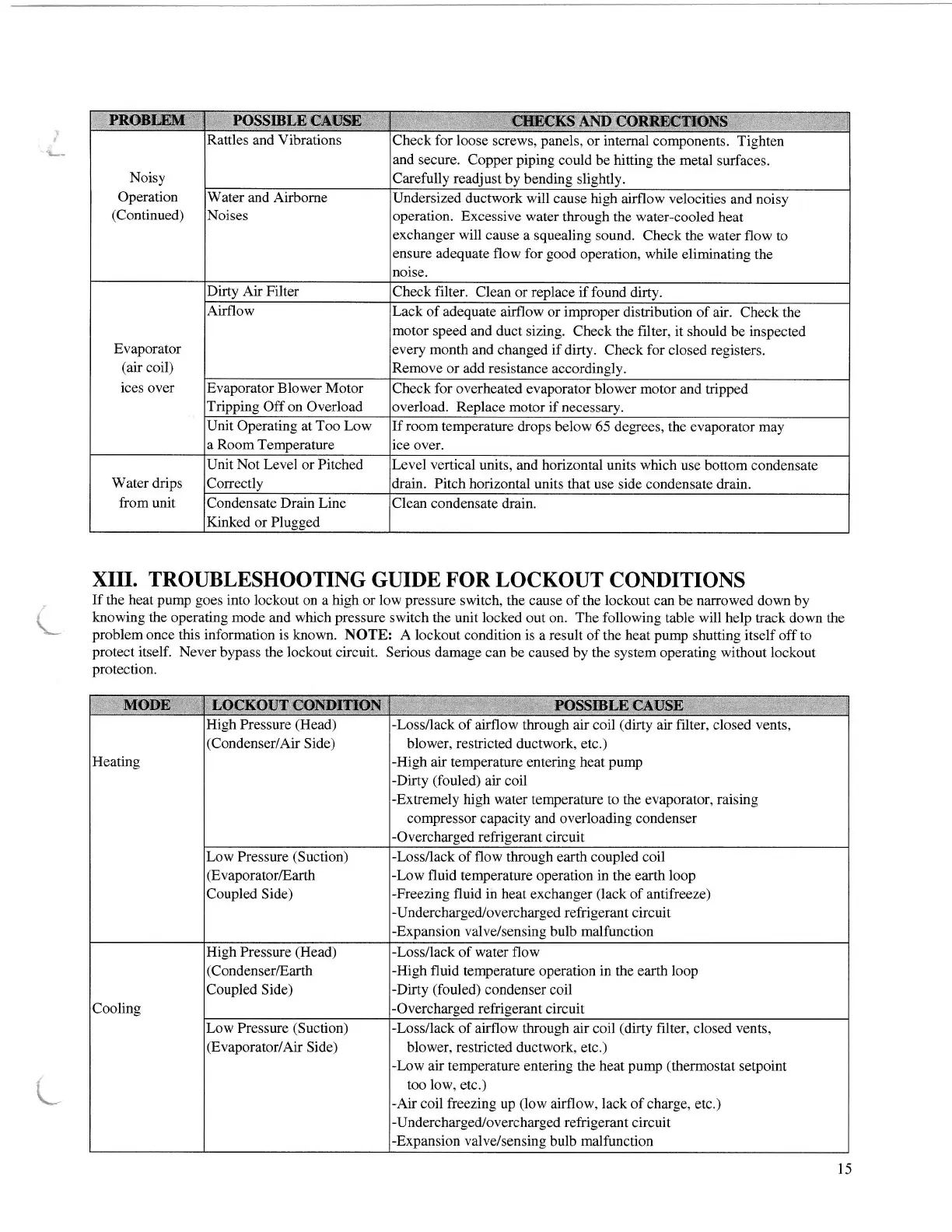

If the heat

pump

goes

into lockout

on a

high

or low

pressure

switch, the cause

of the

lockout

can be narrowed down by

knowing the

operating mode and which

pressure

switch the

unit

locked

out on. The following table will help track down the

problem

once this

information

is known. NOTE: A lockout

condition is a result of the heat

pump

shutting itself off to

protect

itself. Never

bypass the lockout circuit. Serious damage

can be caused by the system operating without lockout

protection.

L

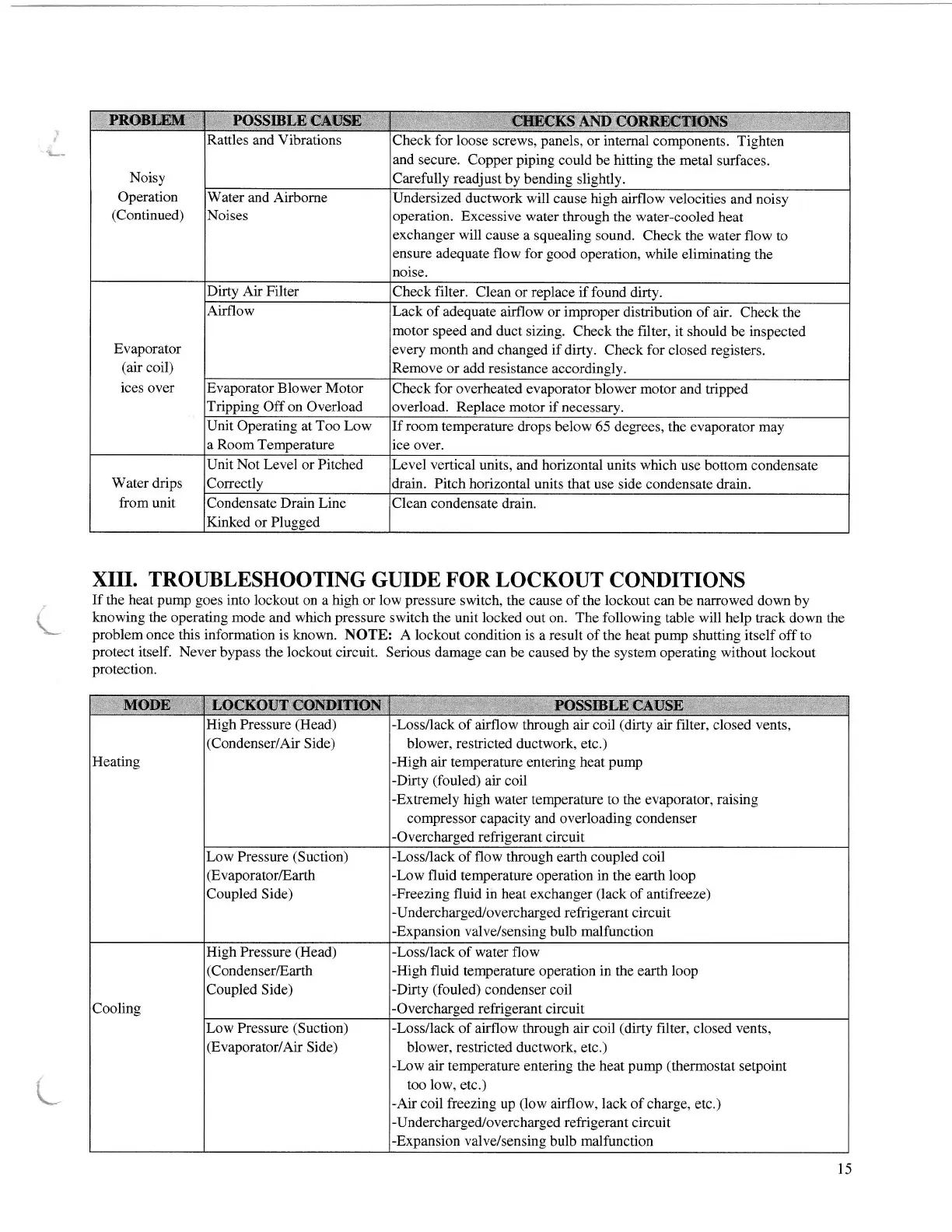

Rattles and Vibrations

Check for loose

screws,

panels,

or internal

components. Tighten

and secure. Copper

piping

could be hitting

the metal surfaces.

Carefully readjust

by

bending slightly.

Noisy

Operation

(Continued)

Water and Airborne

Noises

Undersized

ductwork will

cause high airflow velocities

and noisy

operation.

Excessive

water through the water-cooled

heat

exchanger will cause

a squealing sound.

Check the water flow

to

ensure

adequate flow for

good

operation, while

eliminating the

noise.

Dirty Air Filter

Check

filter.

Clean

or

replace

if found dirty

Airflow

Lack of adequate

airflow or improper

distribution of air.

Check the

motor

speed and

duct sizing. Check the filter, it should

be inspected

every month

and changed if dirty. Check for

closed registers.

Remove or add resistance

accordingly.

Evaporator B lower Motor

Tripping

Off on Overload

Check for overheated

evaporator blower motor

and tripped

overload. Replace

motor if necessary.

Evaporator

(air

coil)

ices

over

Unit Operating

at

Too Low

a Room Temperature

If room temperature

drops below 65 degrees, the

evaporator may

lce over

Unit Not Level or Pitched

Correctly

Level vertical

units, and horizontal

units which use bottom condensate

drain. Pitch horizontal

units that use side condensate drain.

Water drips

from unit

Condensate Drain Line

Kinked or Plugged

Clean condensate drain.

High Pressure

(Head)

(Condenser/Air

Side)

-Lossflack

ofairflow through air coil

(dfuty

air filter, closed vents,

blower, restricted

ductwork, etc.)

-High

air temperature entering heat

pump

-Dirty

(fouled)

air coil

-Extremely

high water temperature to the

evaporator,

raising

compressor capacity and overloading condenser

-Overcharged

refrigerant circuit

Heating

Low Pressure

(Suction)

(Evaporator/Earth

Coupled Side)

-Loss/lack

of

flow

through earth coupled coil

-Low fluid

temperature operation in the earth

loop

-Freezing

fluid in heat exchanger

(lack

of antifreeze)

-Undercharged/overcharged

refrigerant circuit

-Expansion

valve/sensing bulb malfunction

High Pressure

(Head)

(Condenser/Earth

Coupled

Side)

-Loss/lack of water flow

-High

fluid temperature operation in the earth loop

-Dirty

(fouled)

condenser coil

-Overcharged refrigerant

circuit

Cooling

Low Pressure

(Suction)

(Evaporator/Air

Side)

-Loss/lack

of airflow through air coil

(dirty

filter, closed vents,

blower, restricted

ductwork, etc.)

-Low

air temperature

entering the

heat

pump (thermostat

setpoint

too

low,

etc.)

-Air

coil

freezing

up

(low

airflow,

lack

of charge, etc.)

-Undercharged/overcharged refrigerant

circuit

-Expansion valve/sensing

bulb malfunction

l5

PR€3IjM{

POSSI3LACA{'SE

{ffiiCXS AN}

CORAffiTISNS

MODT

LOCKOUT COI{DITIO}\I POSSIBLECAUSE

Loading...

Loading...