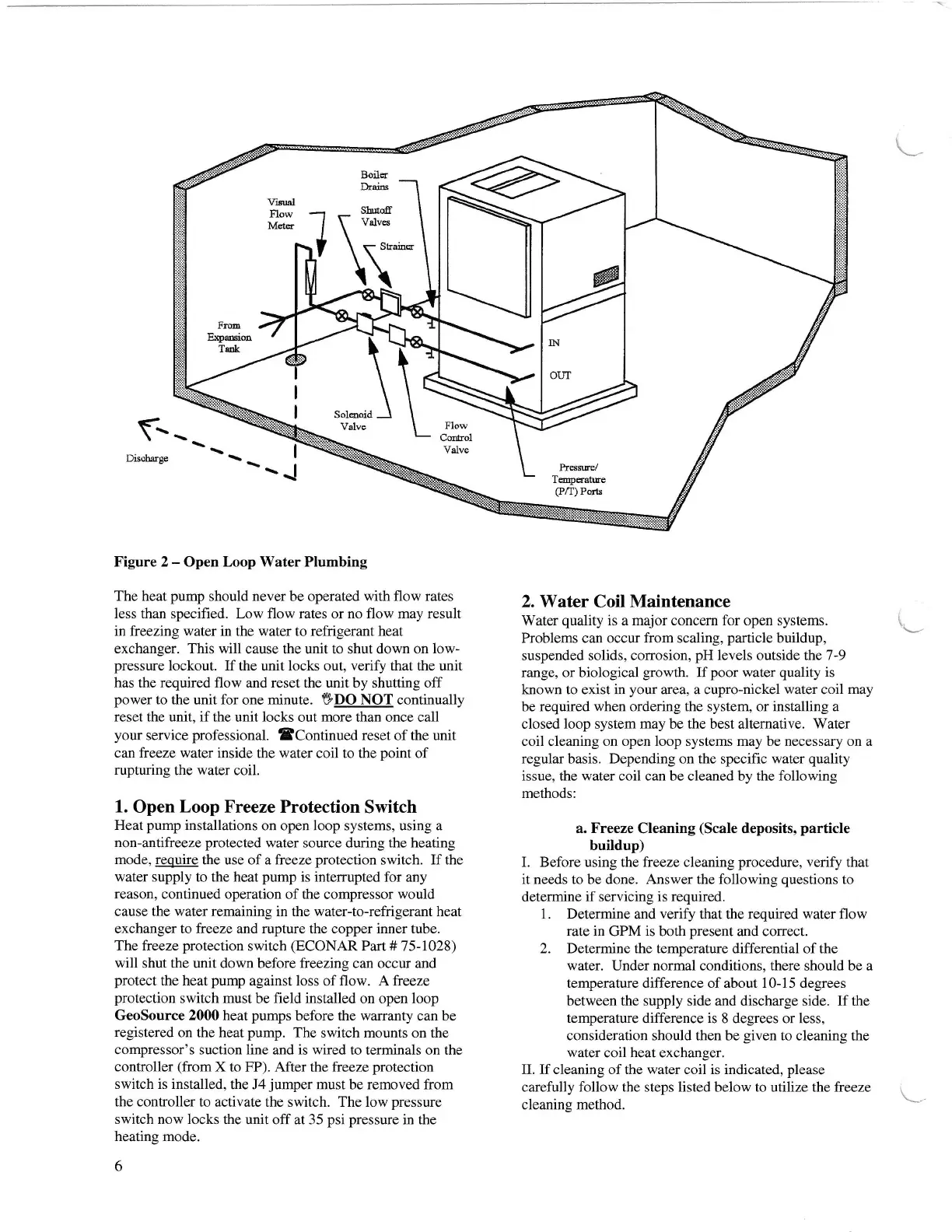

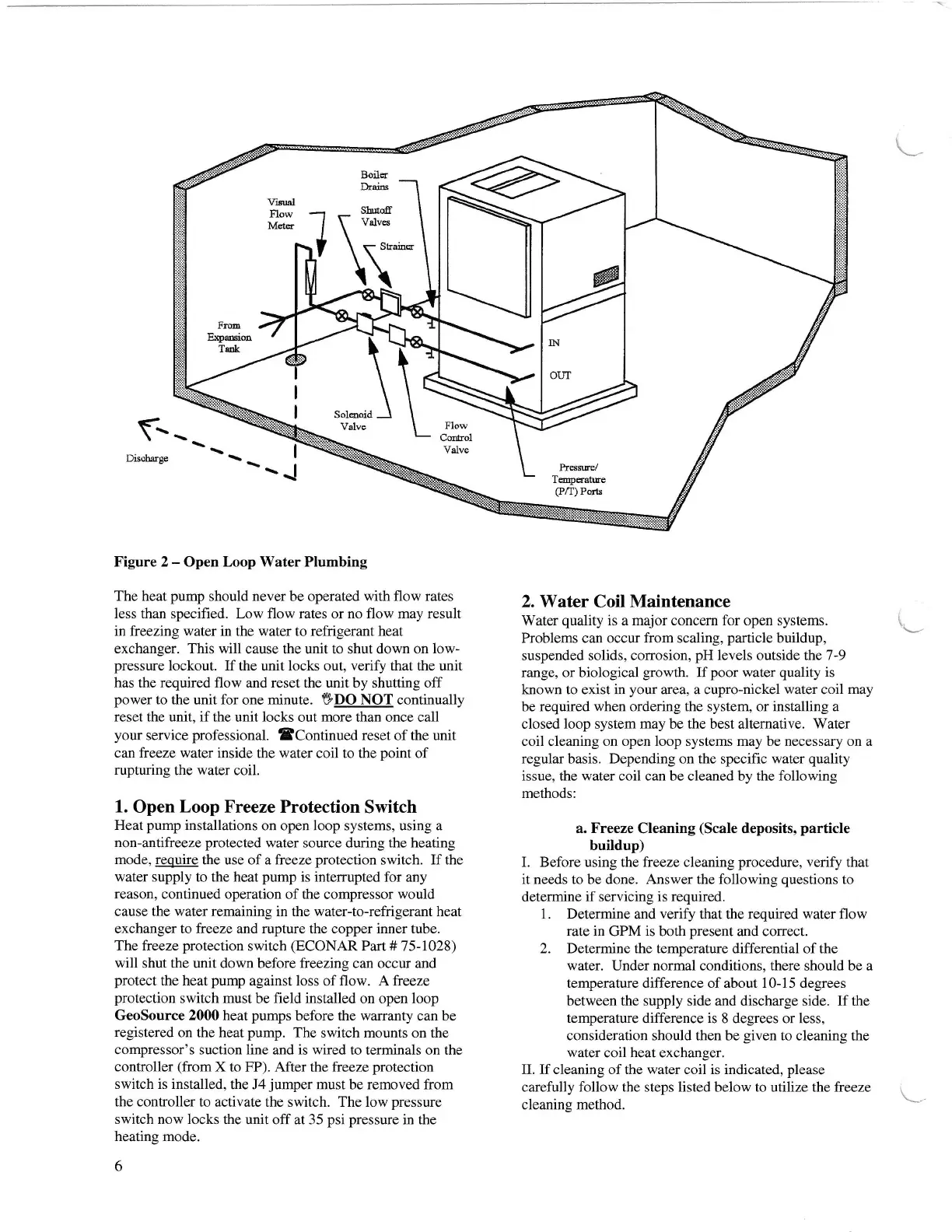

Froa

Exprcion

Tank

Shaotr

Valvs

Staiffi

Vi6ua1

Flow

MEts

Boila

Drais

IN

OUT

Solaoid

Valve

Flow

Cmtrol

Valve

Prsffi1

Topuahrs

(P/T)

Ports

€

Discbrge

--

I

\a

Figure 2

-

Open Loop Water Plumbing

The heat

pump

should never

be operated

with flow rates

less than specified. Low flow rates or no flow may result

in freezing water in the water to refrigerant heat

exchanger. This will

cause the unit to shut down on

low-

pressure

lockout. If the

unit

locks out, verify that the unit

has the required flow and reset the unit by shutting off

power

to the

unit

for

one

minute.

VDO

NOT

continually

reset the unit, if the

unit

locks

out more than once call

your

service

professional.

SContinued reset of the unit

can freeze water inside

the water coil to the

point

of

rupturing

the

water

coil.

1.

Open Loop Freeze Protection

Switch

Heat

pump

installations

on open loop systems, using a

non-antifreeze

protected

water source

during

the heating

mode, requfue

the use of a freeze

protection

switch. If the

water

supply to the heat

pump

is interrupted for any

reason, continued

operation of the compressor

would

cause the water remaining in the water-to-refrigerant heat

exchanger to freeze and rupture the copper inner tube.

The freeze

protection

switch

(ECONAR

Part#75-1028)

will

shut the unit down before freezing can occur and

protect

the heat

pump

against

loss

of flow. Afreeze

protection

switch must

be field installed on open loop

GeoSource 2000 heat

pumps

before the warranty

can be

registered

on the heat

pump.

The switch mounts on the

compressor's suction line

and

is

wired to terminals on the

controller

(from

X to FP). After the freeze

protection

switch is installed,

the J4

jumper

must be removed from

the controller

to activate the switch. The low

pressure

switch now locks

the unit off at 35

psi pressure

in the

heating

mode.

6

2. Water

Coil

Maintenance

Water

quality

is a major

concern

for open systems.

Problems can occur from scaling,

particle

buildup,

suspended solids, corrosion,

pH

levels

outside

the

7

-9

range, or biological

growth.

If

poor

water

quality

is

known to exist ia

your

area, a cupro-nickel water coil

may

be

required when ordering the system, or installing a

closed loop system may be the best altemative. Water

coil cleaning on open loop systems may be necessary on a

regular

basis.

Depending on the

specffic

water

quality

issue,

the

water coil

can be cleaned by

the following

methods:

a.

Freeze

Cleaning

(Scale

deposits,

particle

buildup)

I. Before using the freeze cleaning

procedure,

verify that

it needs to be done. Answer the following

questions

to

determine

if

servicing

is required.

1.

Determhe

and

verify

that the

required

water flow

rate

in GPM

is

both

present

and correct.

2. Determine the temperature differential

of the

water.

Under

normal

conditions,

there

should be a

temperature difference ofabout 10-15 degrees

between the supply side and discharge side. Ifthe

temperature difference is 8 degrees or less,

consideration should then

be

given

to cleaning the

water

coil heat exchanger.

tr. If cleaning of the water coil is indicated, please

carefully follow the steps listed below to utilize

the

freeze

cleaning method.

Loading...

Loading...