5

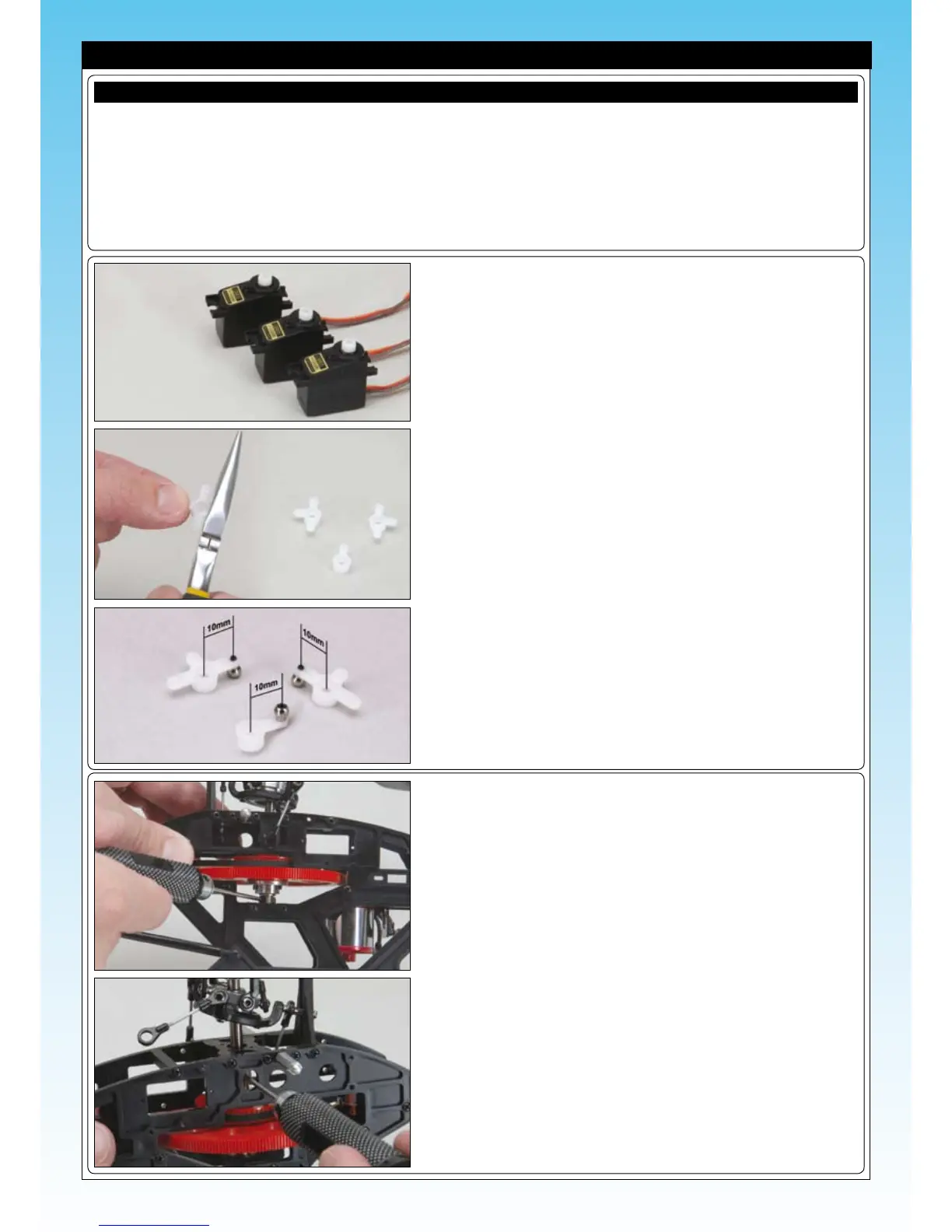

❑ The swashplate is controlled by a 120° CCPM system. Choose three

identical servos - we are using ballraced Cirrus 302BBs.

❑ Remove the servo horns

❑ Trim the servo horns as shown using a pair of pliers or sidecutters. You

need to trim one arm off each of the left/right servo horns and three arms

off the fore/aft servo horn as shown.

INSTALLING THE CYCLIC SERVOS

SERVO INSTALLATION TIPS

●

After installing the balls onto the servo horns, apply a drop of thin C/A to the ends of the threads to lock the screws into place

●

Make sure that you install the servo horn retaining screws to secure the servo horns to the servos

●

Make sure that the servos are centred and that you centre the servo horns and ensure that they're pointing in the correct direction

●

Make sure that you install the balls the correct distances out from the centre of the servo horns

●

Make sure that you install the servos with the servo output shafts pointing the correct direction

●

Tighten the servo mounting screws gently, yet tight enough to hold the servos rmly in place

❑ Locate three mounted balls and install them on the underside of the left/

right servo horns and on top of the the fore/aft servo horn as shown.

❑ Note that all three balls are mounted exactly the same distance out from

the centre on each horn.

❑ Beginners may need to reduce the measurement to 8mm (one hole further

in on the arm) to reduce the control throw.

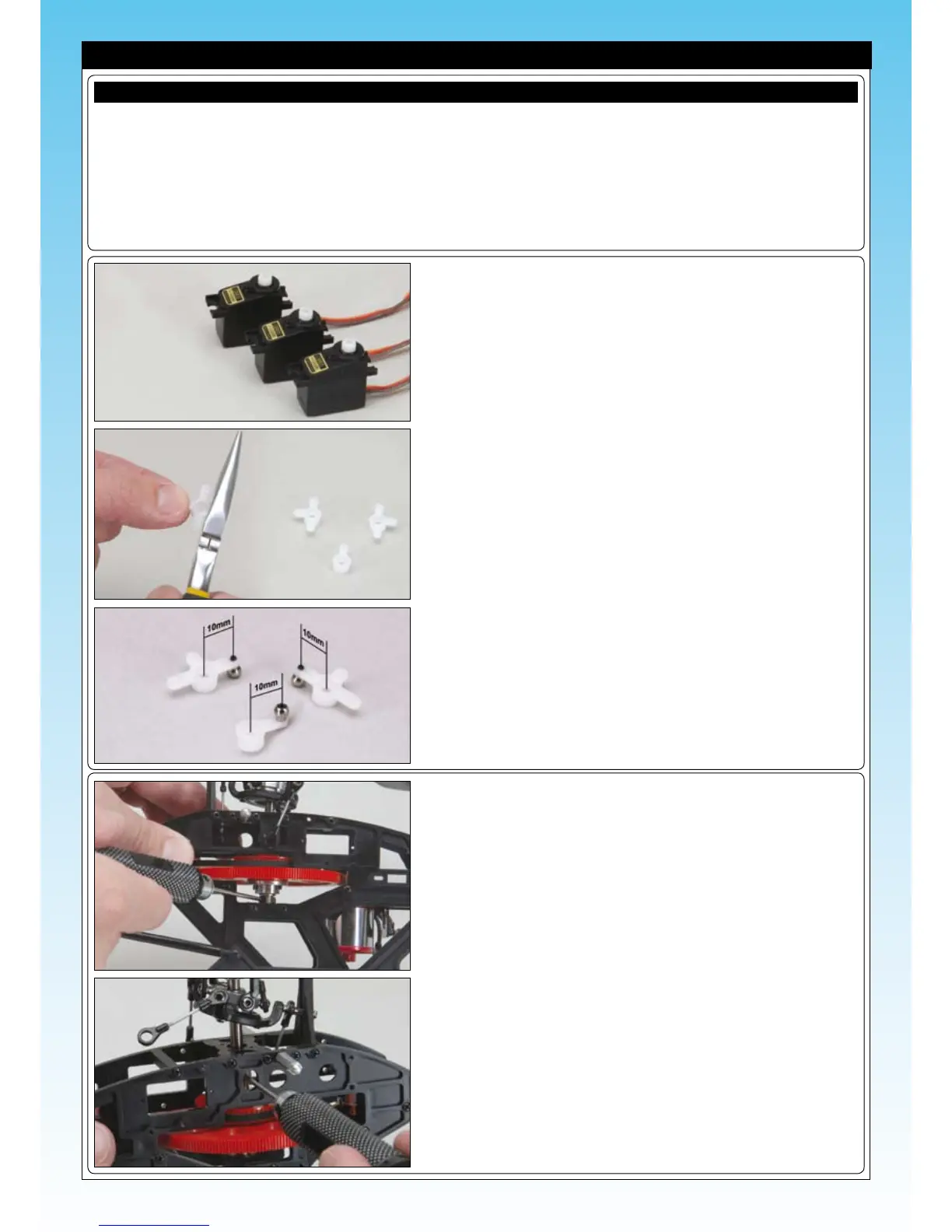

❑ To give sufcient access to install the fore/aft servo, the main shaft needs

to be temporarily removed.

❑ Using an Allen key, remove the lower shaft retaining bolt. Grip the nut on

the other side with a pair of pliers or adjustable wrench.

❑ Loosen the grub screw in the upper retaining collar using the access point

in the main frames as shown. Do not remove the grub screw, just loosen

it.

Loading...

Loading...