16

10. Connection of external appliances & Controls

FACTORY CONNECTIONS

ZoneValve (SHW & SCH Volt Free Inputs)

When the Volt Free contacts are open circuit the boiler will

automatically stop heating the system.

These connections are factory tted, under NO circumstances

should any voltage be connected to these terminals as this will

result in damage to the boilers control electronics.

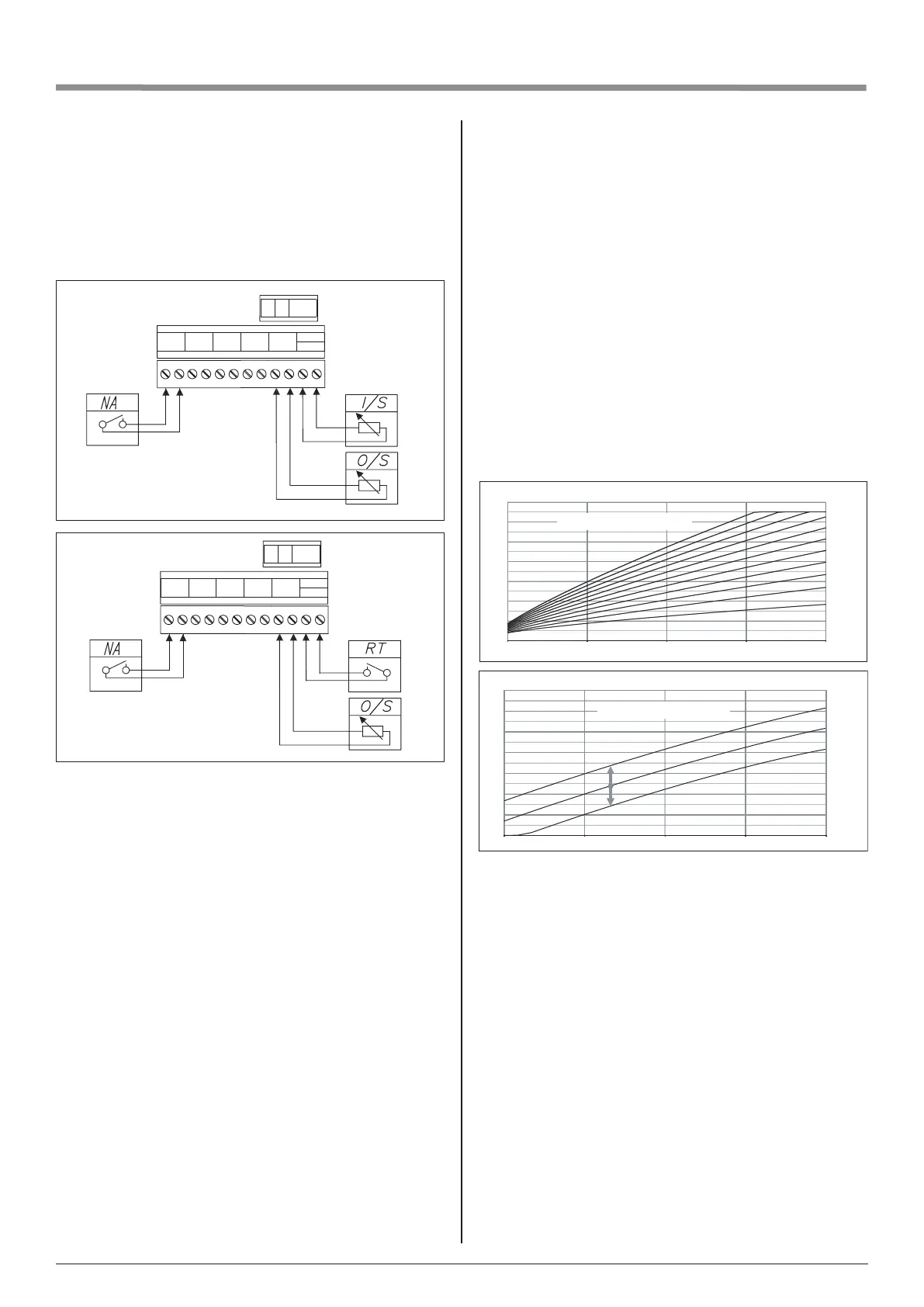

20,0

30,0

40,0

50,0

60,0

70,0

80,0

90,0

-20

-10010

20

Tch [°C]

Temp

outside

[°C]

n=4

n=6

n=8

n=10

n=12

n=14

n=16

n=18

n=20

n=22

n=24

n-no of heating curve (p=0)

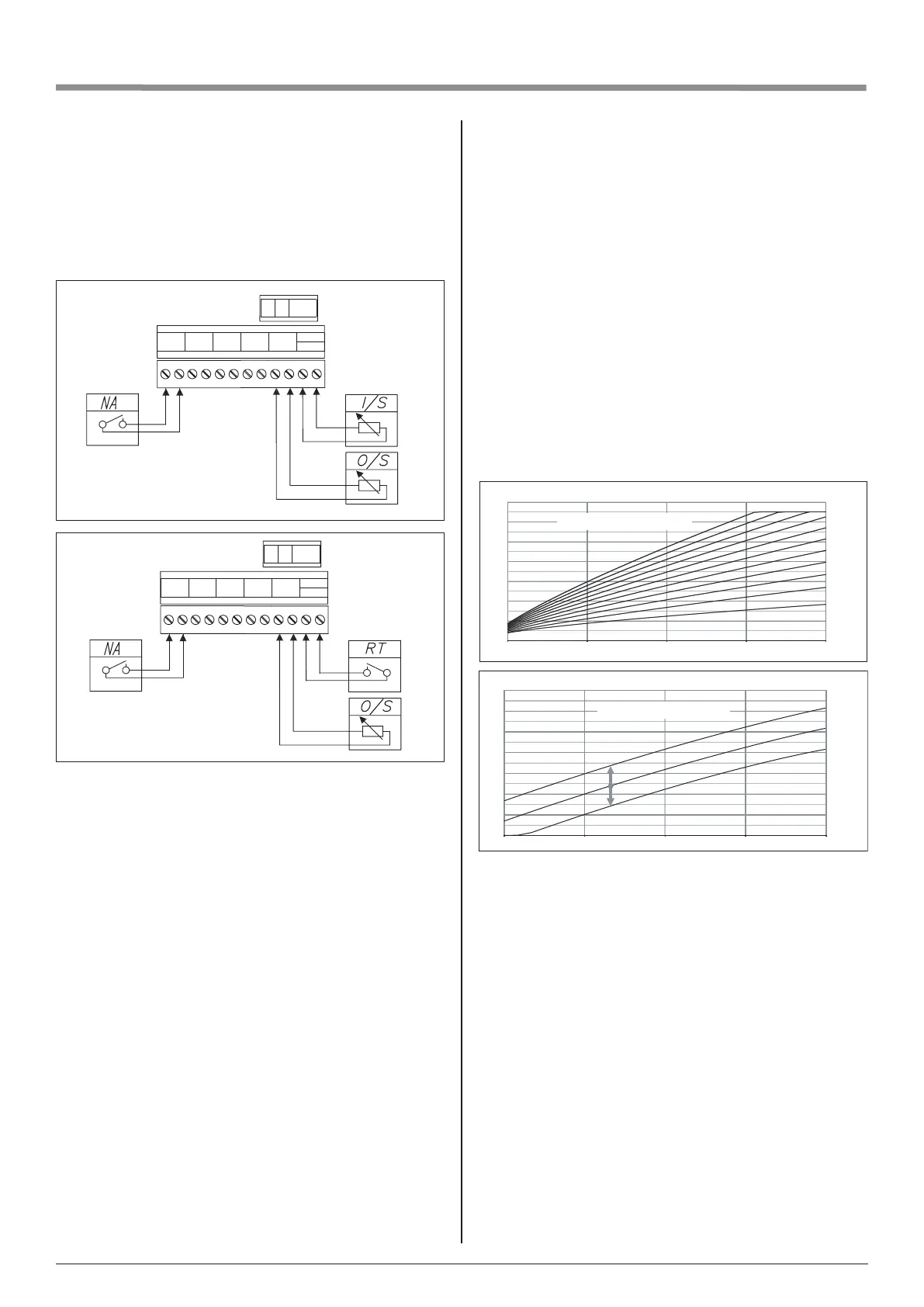

Master Appliance Control (NA)

The NA Connection is used when you have another high current

device installed within the property. i.e. Electric Shower or Water

Heater.

The shower sensor would be connected to the Main Water supply

feeding the shower, the switch wires from the ow sensor will then

be connected to the NA connections shown in Fig:1.

When the shower is in use the ow sensor will create an open

circuit on the NA connections. This will switch the boiler OFF

when the shower is in use protecting the power supply within

the property.

Temperature sensors

The temperature sensor’s cable should be kept as short as

possible. Do not run or twist the sensor cable alongside power

lines or other wiring.

To manually adjust the default CH temperature go to:

SETTINGS > BOILER TEMPERATURE [°C] and select your

appropriate value. The temperature of the CH installation can

be automatically adjusted when the weather compensation is

activated. This can be achieved by activating outside sensor -

O/S (see graph 1 and 2) which activates weather compensation.

To activate weather compensation go to:

CONFIGURATION - CENTRAL HEATING- REGULATION -

WEATHER COMP.

Install the outside temperature sensor (O/S) in the shade, on the

north or northwestern facade of the building, away from windows

and ventilators.

WEATHER COMP – boiler’s controller is responsible for adjusting

temperature in CH installation in accordance with external

(outside) temperature. When the temperature outside the

facility is low, heat demand within the facility is higher, whereas

while the temperature outside is high, analogically, there’s

no need to maintain high temperature within the installation.

The correlation between outside temperature and heating

installation’s temperature can be presented in a graphical

form of so called heating curve. The diagram below presents

a compilation of heating curves for the set point of room

temperature equal 22°C. Depending on the facility characteristics,

climate zone, and the type of heating installation one must select

appropriate heating curve (WEATHER COMP.) Heating curve no

14 (without the offset) is set as a default parameter. If the heating

curve needs to be changed, the OFFSET parameter has to be

adjusted accordingly. The graph below presents a heating curve

no 14 with the offset (-10°C and 10°C).

Tch [°C]

20,0

30,0

40,0

50,0

60,0

70,0

80,0

90,0

-20-1001020

n=14, p=10

n=14, p=0

n=14, p=-10

p - oset of heating curve

Temp

outside

[°C]

I/S

O/S

NA

A B AC

NA SHW SCH Thw O / S

RT

I / S

Fig:1

RT

O/S

NA

A B AC

NA SHW SCH Thw O / S

RT

I / S

Fig:2

Boiler’s operation is dependent on room’s temperature. Room

thermostat (RT) or NTC stat (I/S) have to be installed in the

representative room (such as a living room) away from radiators,

windows, doors, or vents.

• RT activated: the boiler operates according to the time

frames set in the daily/weekly programs; temperature in the

room can only be adjusted manually by using the wireless

thermostat

• I/S activated: the boiler operates according to the time

frames set in the daily/weekly programs and in accordance

with 3 optional temperature settings (selected in the daily

programs): COMFORT, COMOFRT +, COMFROT –

RT is set as a default sensor. In order to change it to NTC stat (I/S)

go to: CONFIGURATION>ROOM TEMP>TEMP SENSOR>I/S

Please note, that the sensors have to be physically

connected to the cable entry points - this can only be done

by an authorized person

Loading...

Loading...