- 34 -

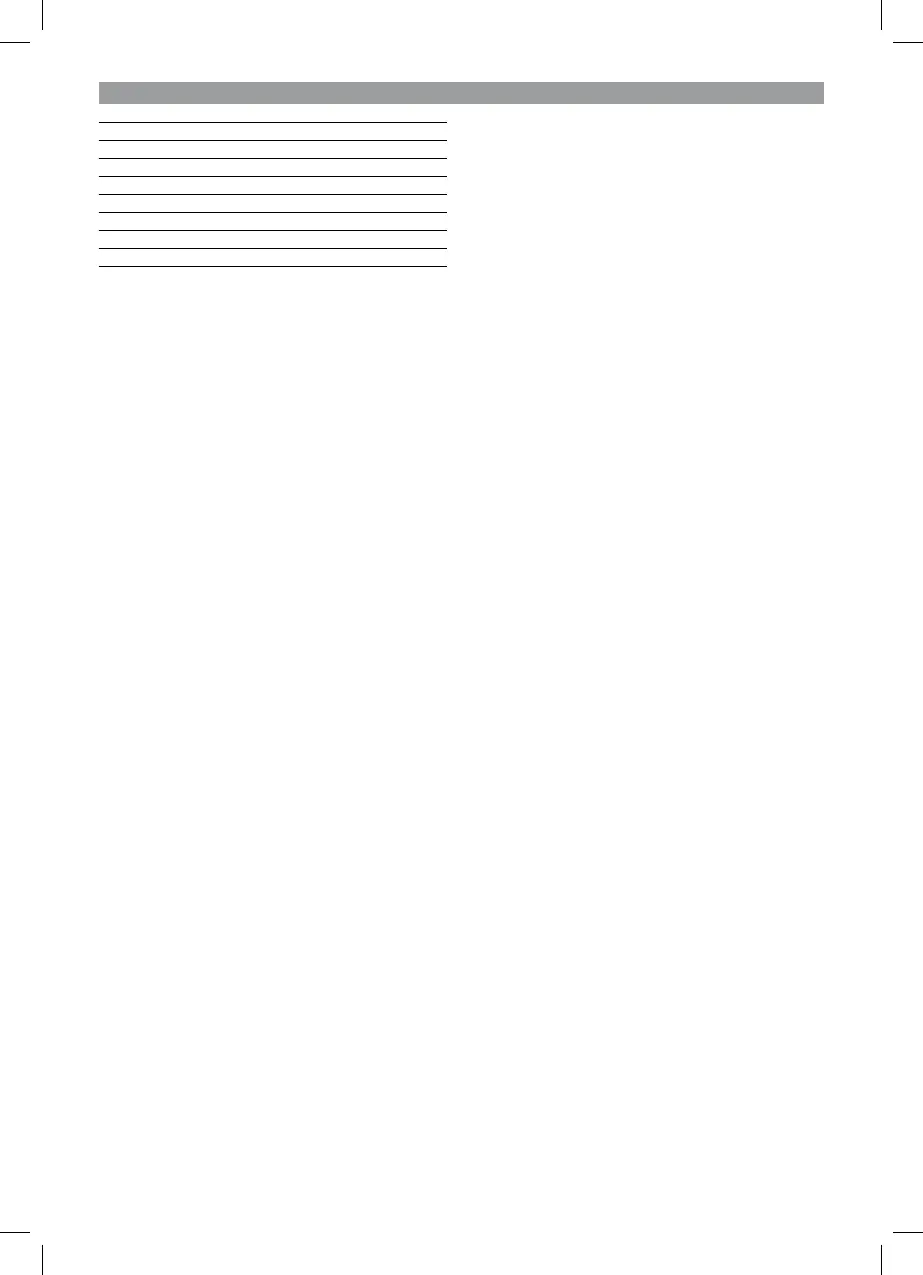

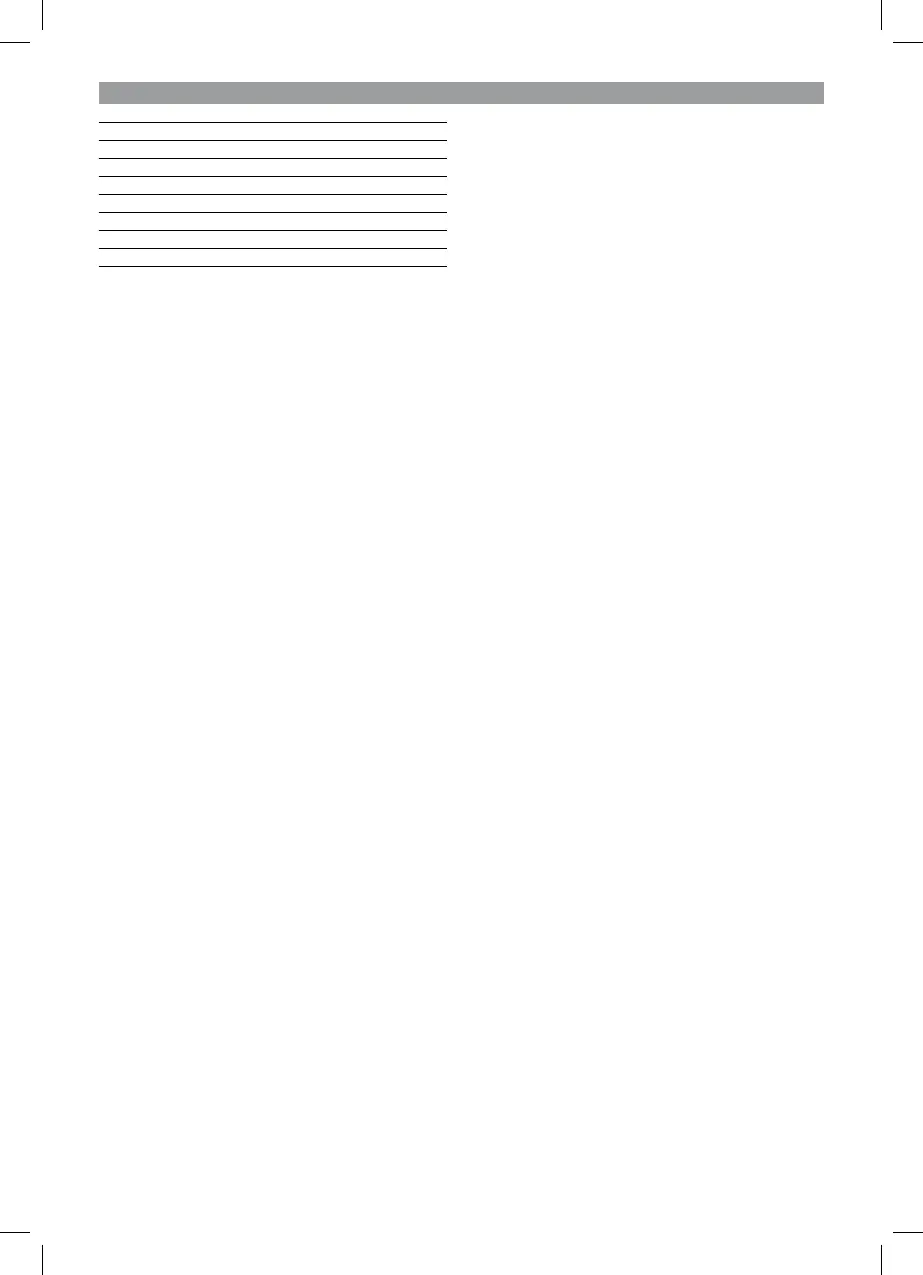

12 640 400 560 2400 2000

13 590 370 515 2200 1840

14 545 340 480 2000 1700

16 480 300 420 1800 1500

18 425 265 370 1600 1300

20 380 240 335 1400 1200

22 350 220 305 1300 1100

25 305 190 270 1150 950

6.10 Countersinking and center-drilling

With this drill you can also perform countersin-

king and center-drilling jobs. Please observe that

countersinking should be performed at the lowest

speed, while a high speed is required for center-

drilling.

6.11 Woodworking

Please note that sawdust must be properly eva-

cuated when working with wood, as it can be a

health hazard. Ensure that you wear a suitable

dust mask when performing work that generates

dust.

6.12 Replacing the V-belt (Fig. 12/14-16)

The V-belt of the pillar drill can be replaced if it

becomes worn. Proceed as described in section

6.4 Speed settings.

In this case replace the V-belt (26) instead of re-

positioning it.

7. Replacing the power cable

Danger!

If the power cable for this equipment is damaged,

it must be replaced by the manufacturer or its

authorized after-sales service or similarly trained

personnel to avoid danger.

8. Cleaning, maintenance and

ordering of spare parts

Danger!

Always pull out the mains power plug before star-

ting any cleaning work.

8.1 Cleaning

•

The pillar drill is maintenance-free to a large

extent. Keep the equipment clean. Pull out

the power plug before doing any cleaning and

maintenance work on the equipment. Do not

use any harsh, abrasive solvents for cleaning

purposes. Make sure that no liquid gets into

the equipment. Re-grease all bare parts when

the work is finished. Particularly the drill pillar,

blank parts of the column, and the drill table

should be re-greased at regular intervals. Use

a standard, acid-free lubricating grease for

this purpose.

•

Note: Do not dispose of oil-soaked rags,

grease-soaked rags, oil residues and grease

residues in your household rubbish. Dispose

of such materials in an environment-friendly

way. Check and clean the ventilation holes

regularly. Store the equipment in a dry room.

If the equipment becomes damaged, do not

try to repair it yourself. Leave such repairs to a

qualified electrician.

•

We recommend that you clean the device

immediately each time you have finished

using it.

•

Clean the equipment regularly with a moist

cloth and some soft soap. Do not use

cleaning agents or solvents; these could at-

tack the plastic parts of the equipment. Ensu-

re that no water can seep into the device. The

ingress of water into an electric tool increases

the risk of an electric shock.

8.2 Maintenance

There are no parts inside the equipment which

require additional maintenance.

8.3 Ordering replacement parts:

Please quote the following data when ordering

replacement parts:

•

Type of machine

•

Article number of the machine

•

Identification number of the machine

•

Replacement part number of the part required

9. Disposal and recycling

The equipment is supplied in packaging to pre-

vent it from being damaged in transit. The raw

materials in this packaging can be reused or

recycled. The equipment and its accessories are

made of various types of material, such as metal

and plastic. Never place defective equipment in

your household refuse. The equipment should

be taken to a suitable collection center for proper

disposal. If you do not know the whereabouts of

such a collection point, you should ask in your

local council oces.

Anl_SA_TC_BD_450_SPK8.indb 34Anl_SA_TC_BD_450_SPK8.indb 34 19.07.2022 13:18:2919.07.2022 13:18:29

Loading...

Loading...