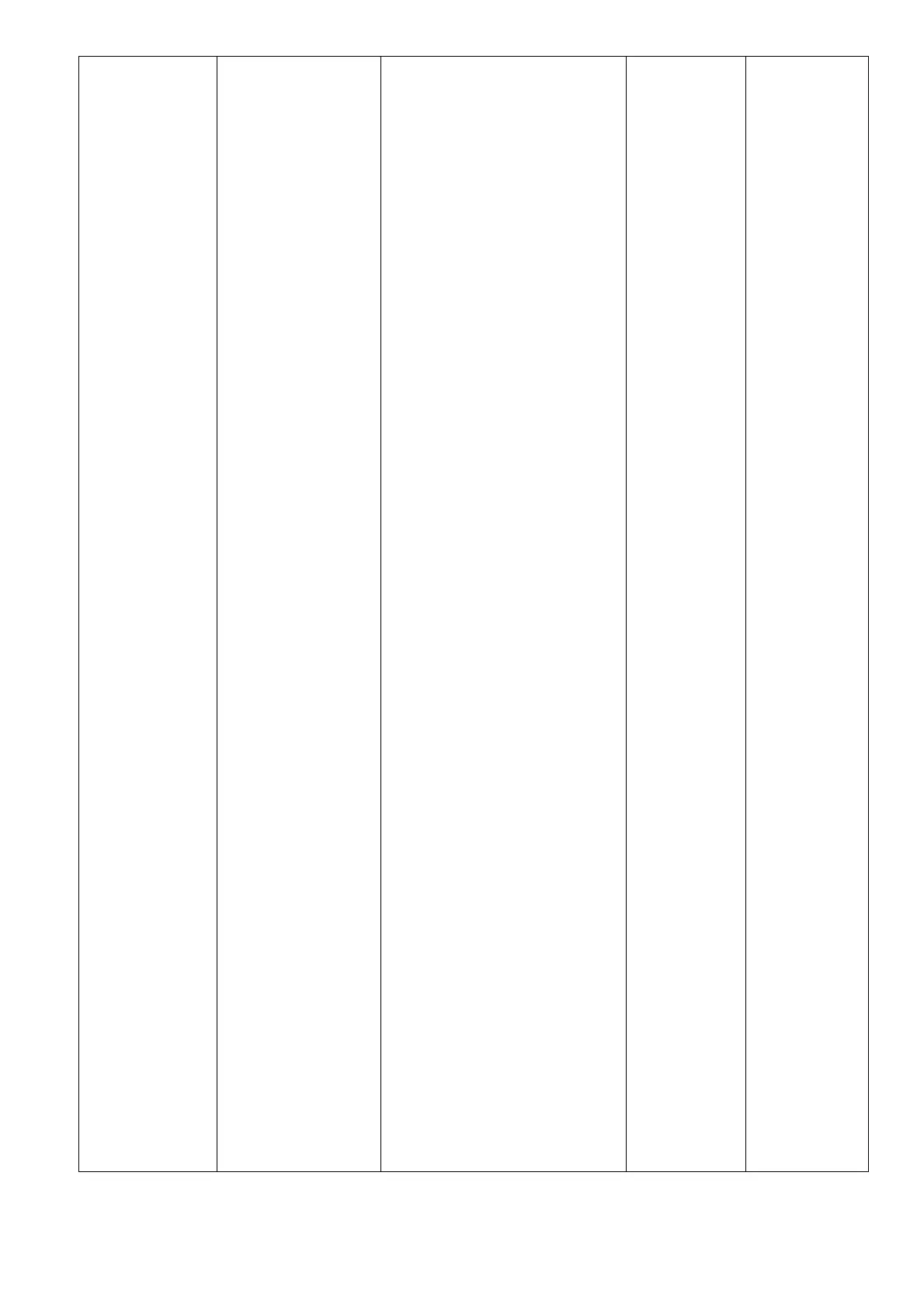

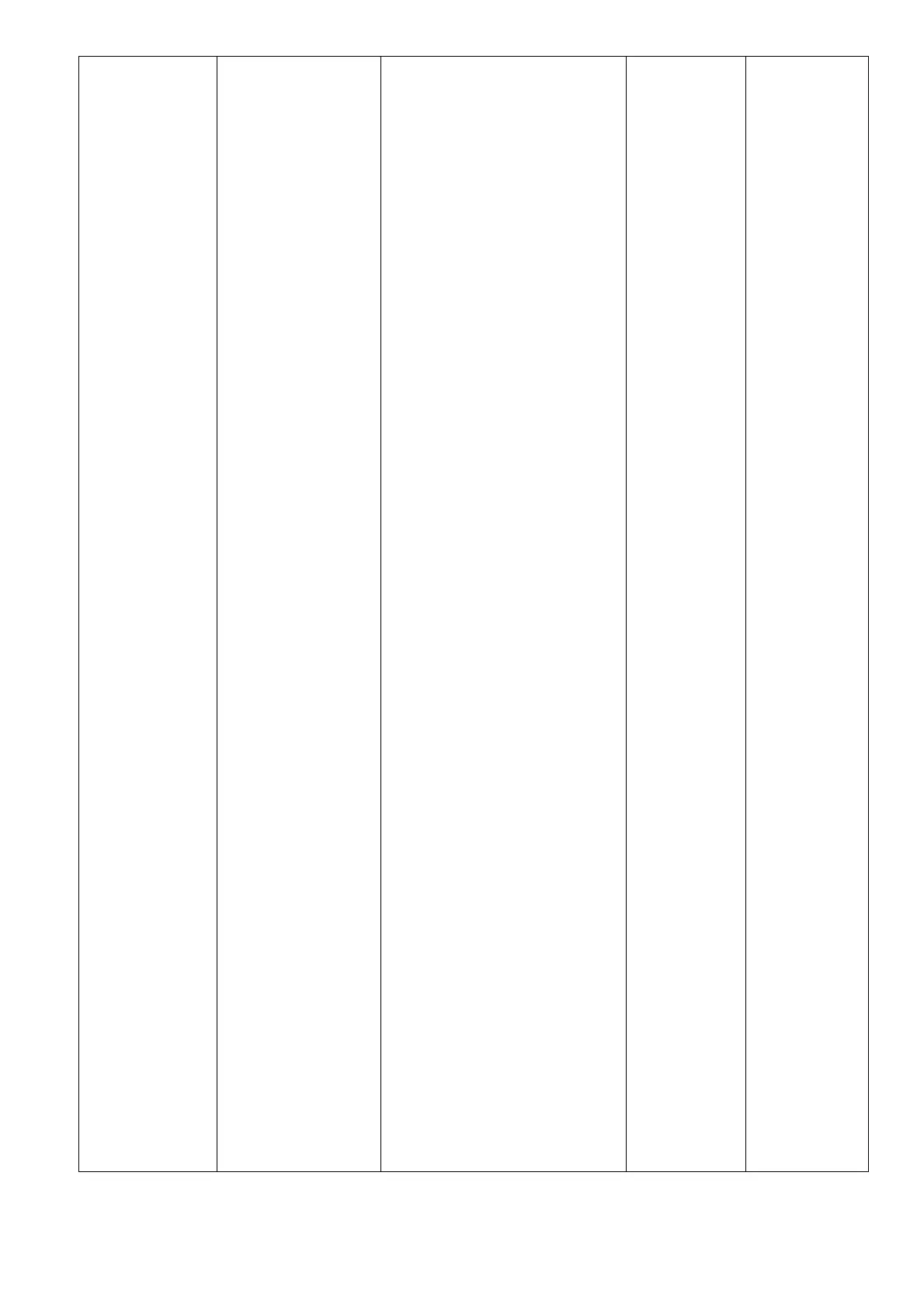

22

IMTP(D) 2.2 – ITTP(D) 2.2/4.0/5.5/7.5 - ELECTROIL

ENG

Pressure Control

1. Pressure Hysteresis

[BAR]

2. Max Pressure *(not

for 2.2M)

3. *(2) Dry working

stop delay [s]

4. *(3) Dry working re-

start time [min]

5. Pipe filling delay [s]

*(not for 2.2M)

6. Filling Pressure limit

[BAR] *(not for

2.2M)

7. *(4) Minimum flow

stop delay [s]

8. *(5) Minimum flow

restart delay [s]

9. Alarm restart delay

[s] *(not for 2.2M)

10. *(6) Dry operating

PF limit

11.

*(7) Enable OFF

Stop Delay

(from

V.11.08)

12. *(8) DP-flow

reduction power [%]

13. *(9) DP-flow

reduction max value

[%]

14. *(10) Alternating

time [min]

15. *(11) Intake

pressure

1. Pressure control hysteresis

2. Max Pressure *(not for 2.2M)

3. *(2) Dry working stop delay time

for pump filling

4. *(3) Dry working re-start delay

time after firsts 5th times; after

the 5

th

, the Inverter require a

manual re-start (STOP +

START) *(not for 2.2M)

5. Pipe filling time at the minimum

speed when the pressure

measured during the motor

starting is lower than the Filling

Pressure Limit (next point) *(not

for 2.2M)

6. Pressure limit for the reduces

speed motor starting, during pipe

filling

7. *(4) Delay time for the Minimum

flow protection stop (only for the

Absolute pressure control)

8. *(5) Delay time for the motor re-

start after the minimum flow stop

– (only for the Absolute Pressure

control);

9. Delay time to re-start the motor

after a protection stop

10. *(6) When the Power Factor

undertake this value, the pump

stop for dry operating protection

11. *(7) Switch-off delay after EN

contact opening

(from V.11.08)

12. *(8) Power value limit for the

reduction of the Differential

pressure

13. *(9) Differential Pressure

reduction when the power is

under the limit of previous point

14.

*(10) Time of the alternating

starting priority of two or more

pumps in Master-Slave group

mode

15. *(11) Intake pressure setting:

make use to avoid over-

elongation with intake pressures

over 2 Bar; the minimum

reference pressure will be the

same to the intake pressure +

0.5 Bar + hysteresis.

0.1 .. 3.00 bar

110 .. 200%

10 .. 300 s

*(0.1 .. 25’)

0.1 .. 45’

0 .. 999 s

0.1 .. 30 bar

*(1 .. 99 s)

4 .. 120 s

0 .. 120 s

4 .. 180 s

0 .. 0.90

*(0÷99s)

*(110 .. 200%)

105 .. 120%

*(70 .. 100%)

20 .. 100%

*(1 .. 999)

2 .. 9999

P. Absolute:

0.3 bar

Differential:

0.05 bar

125%

40 s

15’

0 s

0.5 bar

12 s

15 s

0

10 s

*(0.45)

0.5

0s

120%

85%

100%

60

0 bar

Loading...

Loading...