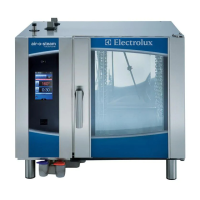

This document provides comprehensive instructions for the installation, operation, and maintenance of Electrolux Professional Electric Combi-Convect Ovens, available in 6 GN 1/1, 6 GN 2/1, 10 GN 1/1, 10 GN 2/1, 20 GN 1/1, and 20 GN 2/1 grid models. These ovens are designed for industrial use, specifically for cooking food, and are not intended for household use.

Function Description:

The Electrolux Professional Electric Combi-Convect Ovens are advanced cooking appliances featuring digital temperature control and a thermostatic probe for precise core temperature measurement. They offer various cooking modes including air-convection, mixed (superheated steam), steaming, and regeneration cycles. Special cooking modes like "Cook and Hold" (HOLD) and "ECO-DELTA" cooking for large food pieces are also available. The ovens are equipped with an automatic cleaning system (AIR-O-CLEAN) with multiple cycles for different soil levels. For enhanced safety, they include a double-action door opening mechanism to protect against scalding steam and a double-glazed oven door for reduced heat dispersion. The self-diagnostics system indicates oven faults using error codes. HACCP (Hazard Analysis and Critical Control Points) functionality allows for recording cooking programs to ensure compliance with food safety standards. The ovens support automatic sequential multiphase cooking programs, allowing for complex cooking processes with up to six phases.

Important Technical Specifications:

The ovens operate on 3-phase electrical supply at 208V or 240V, 60Hz. Current ratings vary by model, ranging from 32amps for 6 GN 1/1 models to 150amps for 20 GN 2/1 models. Total power consumption ranges from 10.1 kW to 49.5 kW. Maximum load capacities for food range from 66 lbs (30 kg) to 440 lbs (200 kg). Net weights vary from 254 lbs (115 kg) to 860 lbs (390 kg). Shipping dimensions also vary, with widths from 38 3/4"inch (985 mm) to 44 11/16"inch (1135 mm), heights from 42 1/8"inch (1070 mm) to 81 1/8"inch (2060 mm), and depths from 37 5/8"inch (955 mm) to 51 3/16"inch (1300 mm). Noise emission data indicates that generated noise does not exceed 70 dB (A). Water supply connections require a 3/4" NPT gasline for water inlet "N" (steam condensation system) with total hardness up to 400ppm (40°fH) and pressure 22-36 psi (150-250 kPa). Water inlet "B" (steam production system) requires 0.5-5°fH (5-50ppm) total hardness and the same pressure range. Chlorine ion concentration should not exceed 10 ppm, and pH should be over 7. The water drain system requires a 1 1/4" NPT gasline outlet, with a minimum gradient of 5% and resistance to temperatures up to 212°F (100°C).

Usage Features:

The control panel is divided into manual and automatic sections, offering flexibility in operation. Users can select cooking modes, set temperature (up to 572°F/300°C), cooking time, and humidity levels. The core temperature probe allows for precise cooking based on internal food temperature. The "Pause phase" function allows for delayed starts or intervals between cooking cycles. "Regeneration cycle" provides ideal humidity for rapid heating. "HOLD" mode is for long, slow cooking. The "Clean Cycle" offers automatic or semi-automatic oven cleaning. Cooking programs can be stored, edited, and retrieved by number or name. The oven features a "Delay Start" function for scheduled cooking. Manual water injection is available to boost humidity. An LED indicates when the boiler needs descaling, and a button allows for manual boiler draining. Rapid oven cooling is useful for switching between cooking types requiring different temperatures.

Maintenance Features:

Routine maintenance components are easily accessible by opening the control panel, removing the left side panel, or the rear panel. The manual emphasizes the importance of periodical boiler descaling, indicated by an LED. Descaling can be performed using pure vinegar or chemical descalers, with specific instructions provided for each method. Regular cleaning of the oven interior with an oven cleaner is recommended daily. The oven door glazing panels can be cleaned by opening the internal panel. The rotary spray arm of the cleaning system should be cleaned periodically, especially if nozzles are blocked or with hard water. The oven door seal is a consumable component and should be replaced when it hardens or cracks. The grease filter and air filter should be cleaned regularly. Stainless steel surfaces should be washed with lukewarm soapy water and dried thoroughly, avoiding abrasive tools or chlorine-containing products. For prolonged disuse, the appliance should be disconnected from power, water valve closed, and stainless steel surfaces rubbed with petroleum jelly for protection. Troubleshooting information is provided for common malfunctions, including heating issues, steam production problems, and incorrect temperature readings, with corresponding error codes.