28

Replacing the injectors

1. Remove the pan supports.

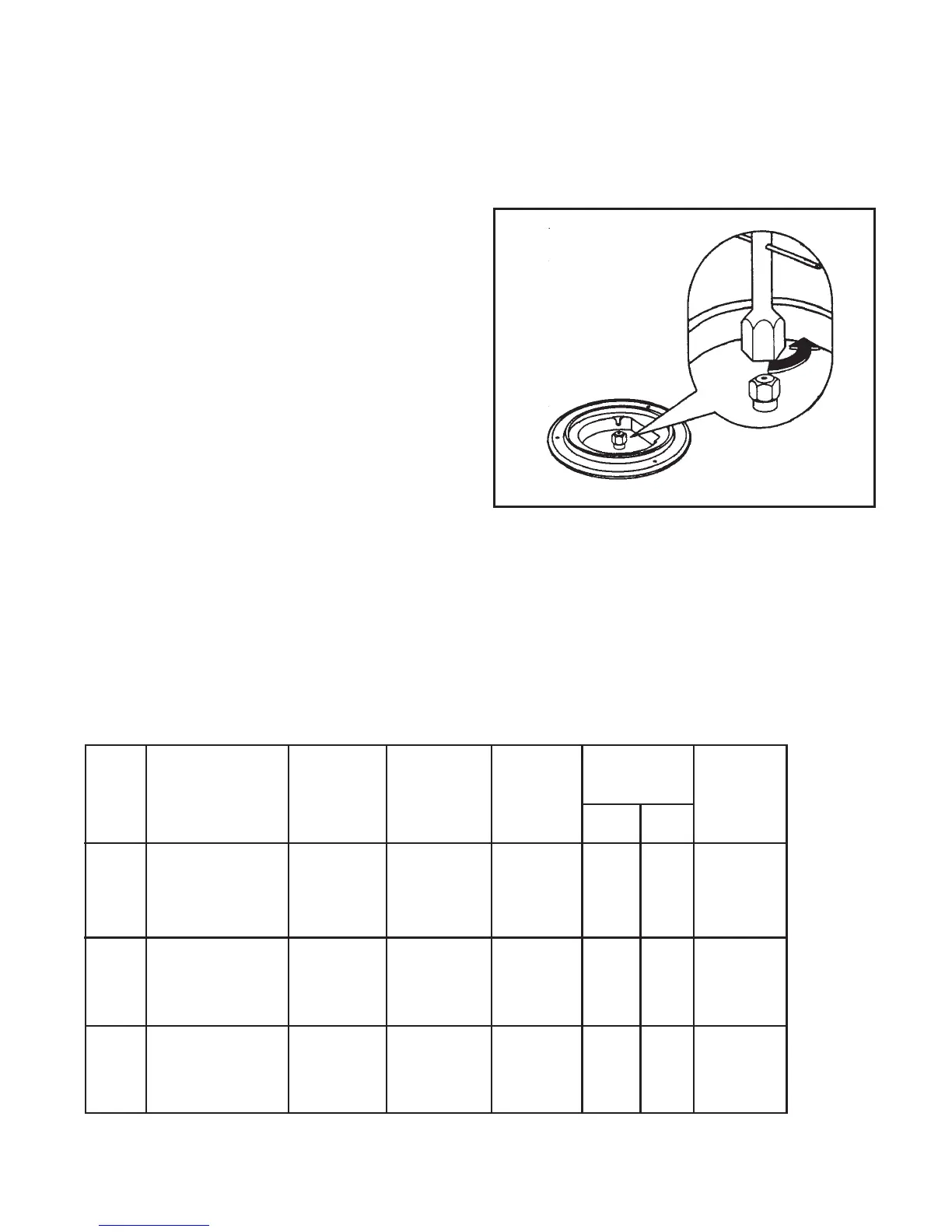

2. Remove the burner caps and crowns.

3. Using a 7 mm socket spanner unscrew

and remove the injectors, then replace

them with the ones required for the new

type of gas (see table “Burner

characteristics”).

4. Reassemble the parts, following the

same procedure backwards.

5. Replace the Gas Type Label (located

near the gas supply connection) with the

one corresponding to the new type of

gas. The label is supplied in the

accessories plastic bag.

Should the feeding gas pressure be different

or variable compared with the required

pressure, an appropriate pressure regulator

must be fitted on the gas supply pipe, in

compliance with the rules in force.

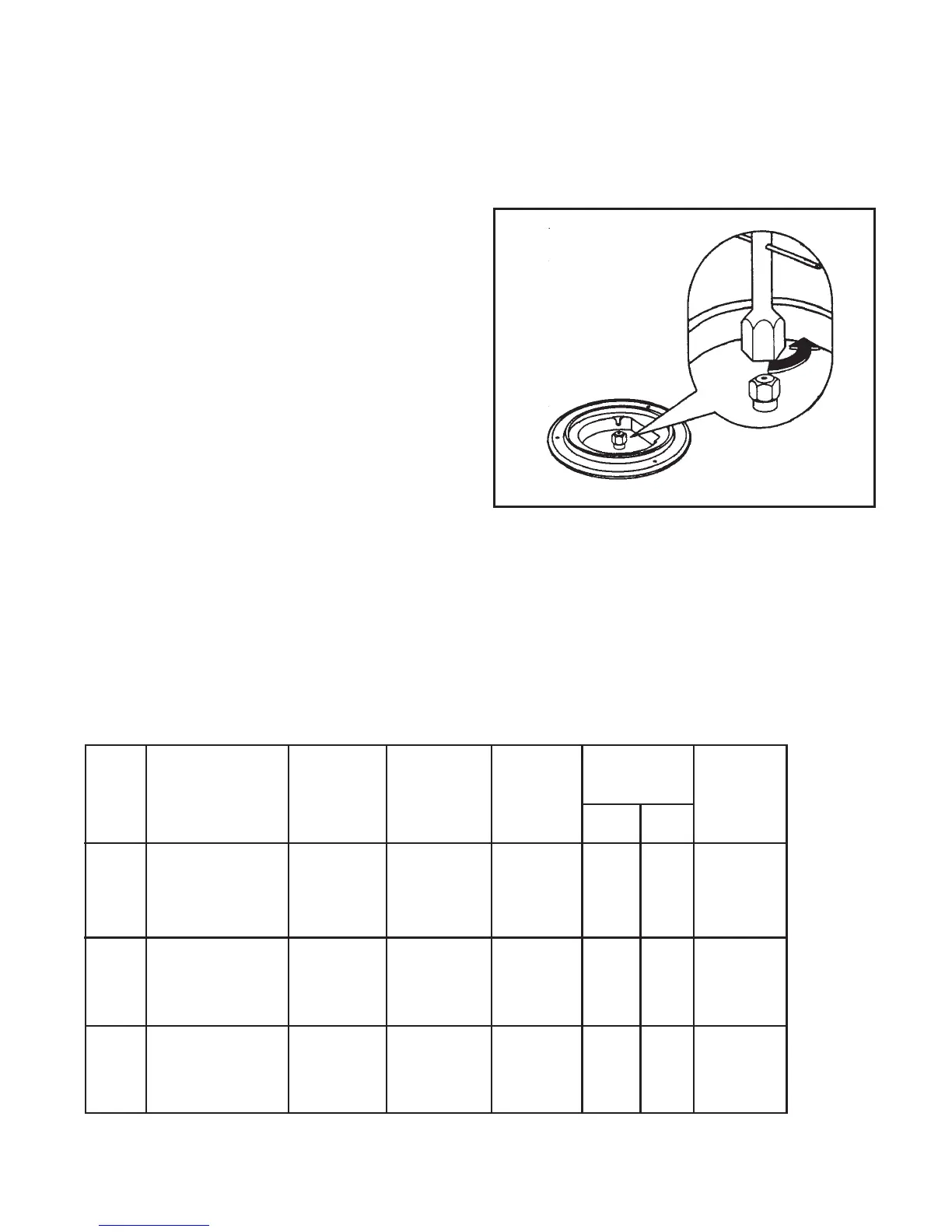

Adaptation to different types of gas

Burner characteristics

TYPE BURNER INJECTORS NORMAL REDUCED NORMAL FEEDING

OF GAS POWER POWER POWER PRESSURE

1/100 mm kW kW m

3

/h g/h mbar

Rapid 119 2,9 0,65 0,276 -

Semi-rapid 96 1,9 0,45 0,181 - 20

Auxiliary 70 1,0 0,33 0,095 -

Rapid 86 2,7 0,65 - 196

Semi-rapid 71 1,9 0,45 - 138 30

Auxiliary 50 1,0 0,33 - 73

Rapid 108 1,9 0,65 0,201 -

Semi-rapid 105 1,4 0,45 0,148 - 13

Auxiliary 80 0,9 0,33 0,095 -

* Injectors for natural gas G20 13 mbar are for Russia only

NATURAL

GAS

LIQUID

GAS

NATURAL

GAS

*

Loading...

Loading...