13

F INSTALLATION AND ASSEMBLY

F1 Customer responsibilities

The Customer must provide for the following:

- Install a disconnecting switch with a capacity at

least equal to that given in the technical data table,

a 30mA residual current circuit breaker and an

overcurrent device (magnetothermal cut-out with

manual reset or fuse) between the appliance and

the mains power outlet. The chosen device must be

lockable in the open position in case of mainte-

nance.

- install an adequate electrical power supply ahead

of the machine, according to the equipment’s tech-

nical specifications (Table 1 and D2 “Characteris-

tics of power supply”);

- the equipotential connection of the workplace elec-

trical system to the metal structure of the machine

by means of a copper cable of adequate section

(see position “EQ” in par. F6.2 “Installation dia-

grams”);

- Adducting for the electrical connection between the

workplace electric panel and the equipment;

- the water supply and drain connections and other

connections as indicated in Table 1 and par. F6

“Plumbing connections”;

F2 Characteristics of the place of machine

installation

The machine is designed for installation in professional

and not domestic-type kitchens. Water collection traps/

metal grates must be arranged in the floor at the

machine discharges (see pargraph F6.2 “Installation

diagrams”), possibly replaceable with a single water

trap sized for a flow rate of at least 3 l/s.

F3 Machine space limits

A suitable space must be left around the machine (for

operations, maintenance, etc.).

The passages enabling personnel to operate on the

machine must be at least 50 cm wide, except at the

rear of the machine.

The size must be increased in case of use and/or

transfer of other equipment and/or means or if exit

routes are necessary inside the workplace.

F4 Positioning

The machine must be taken to the place of installation

and the packing base removed only when being

installed.

Arranging the machine:

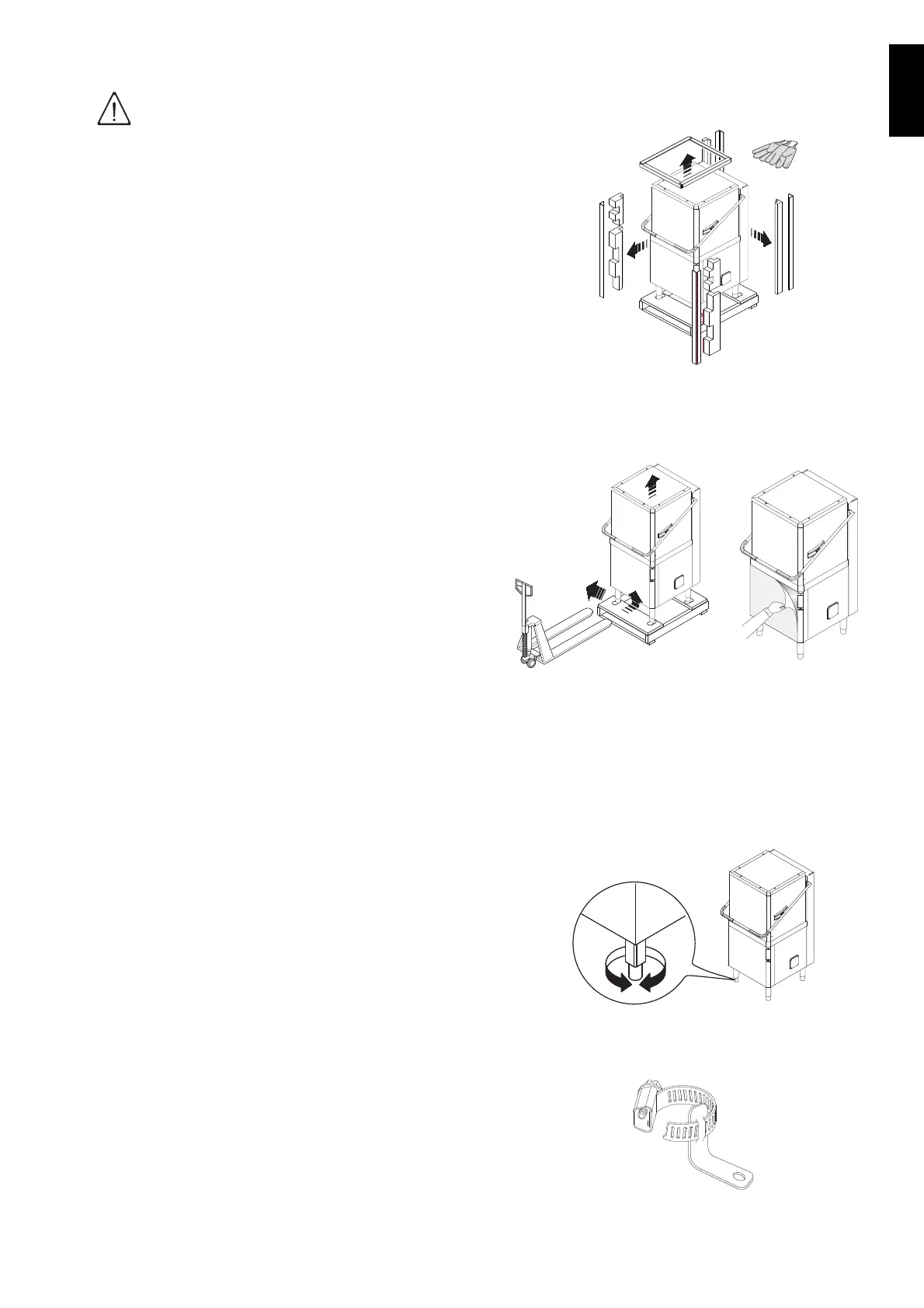

• Wear protective gloves and unpack the machine

(Figure 5).

Figure 5 Unpacking

• Lift the appliance using a lift truck, remove the base

and position the appliance where it is to be installed

(

Figure 6).

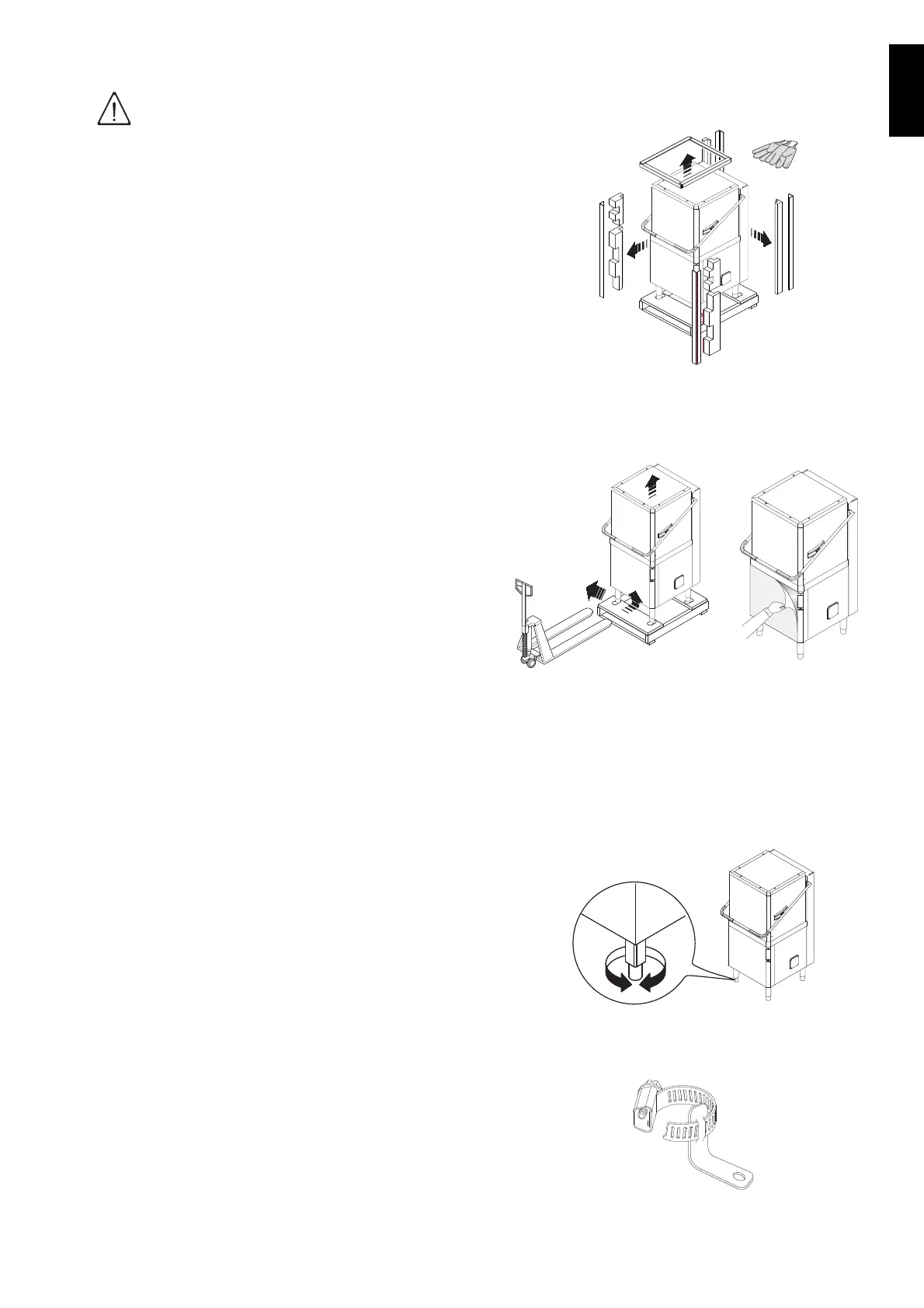

• Carefully remove the protective film from the outer

panels without tearing it, to avoid leaving traces of

glue (Figure 7).

• Adjust the equipment by turning the special adjust-

able feet and making sure it is perfectly level, both

lengthwise and crosswise (Figure 8).

Figure 8 Feet adjustment

• The appliance must be fixed to the floor using the

two clamps supplied

(Figure 9).

Figure 9 Machine fixing clamp

IMPORTANT!

Machine installation operations must

only be carried out by specialized Techni-

cians provided with all the appropriate

personal protection equipment (safety

shoes, gloves, glasses, overalls, etc.),

tools, utensils and ancillary means.

Figure 6 Machine

positioning

Figure 7 Removing

the film

Loading...

Loading...