26

HSTARTING

H1 Preliminary checks, adjustments and

operational tests

H1.1 Electrical and plumbing checks

Before starting the machine:

• check correct connection of the electrical wires that

feed the machine;

• make sure the power supply voltage and frequency

match the data given in Table 1;

• check correct connection of the water supply and

drain pipes (see par. F6 “Plumbing connections”)

• make sure all the guards and safety devices are in

place and efficient.

H1.2 Check the positioning of tank components

H1.2.1 Check the fitting of filters and overflows

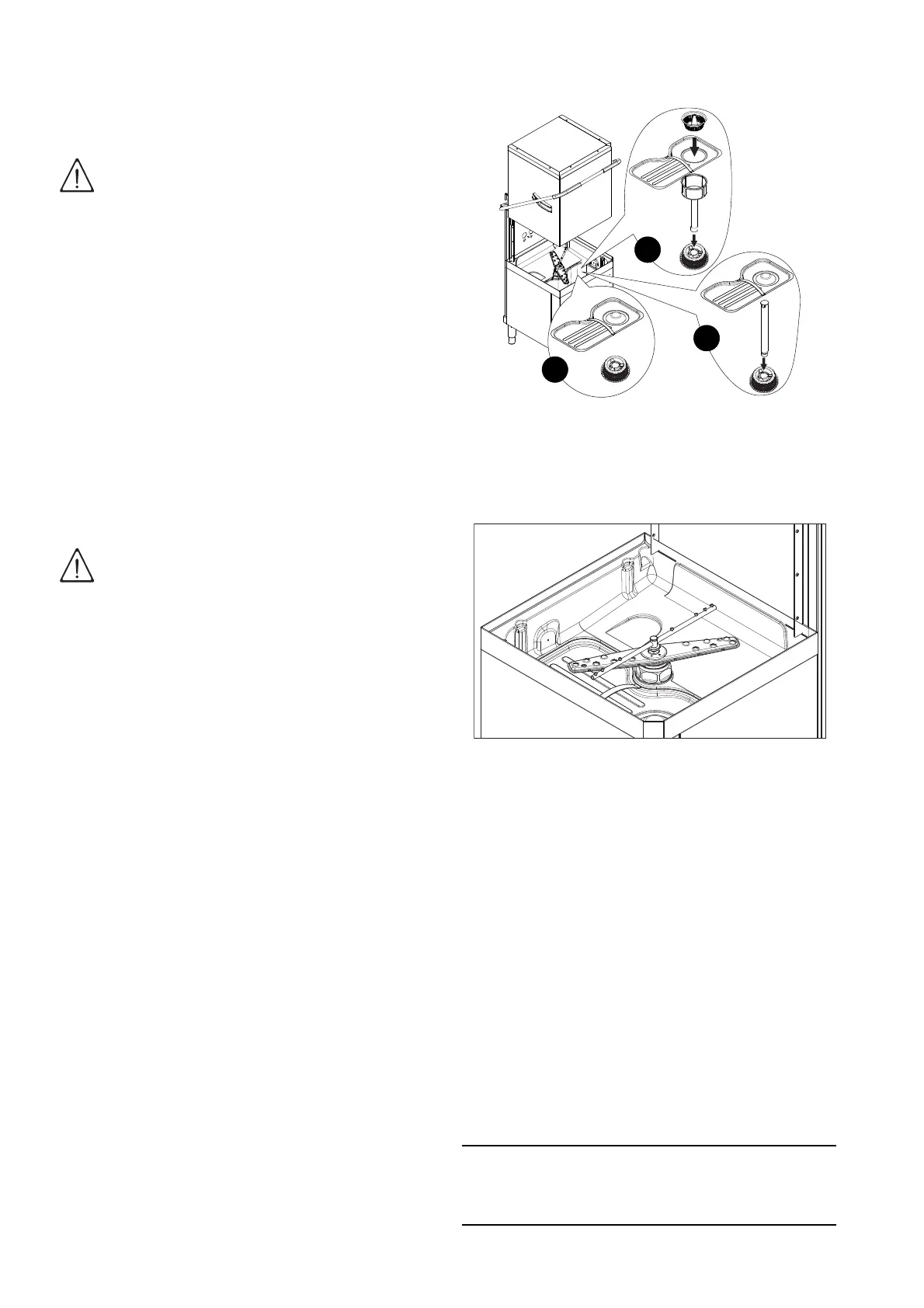

In versions with supplementary filtering system (FS),

make sure the pump suction filter "1", the tank filter "2",

the flat filter "3" and the basket filter "4" are correctly fit

-

ted ("A" - Figure 17).

In versions without supplementary filtering system

(FS) and without drain pump, make sure the filter "1",

the overflow "2" and the flat filter "3" are correctly fitted

("B" -

Figure 17).

In versions without supplementary filtering system

(FS) and with drain pump, make sure the pump suction

filter "1" and the flat filter "3" are correctly fitted ("C" -

Figure 17).

.

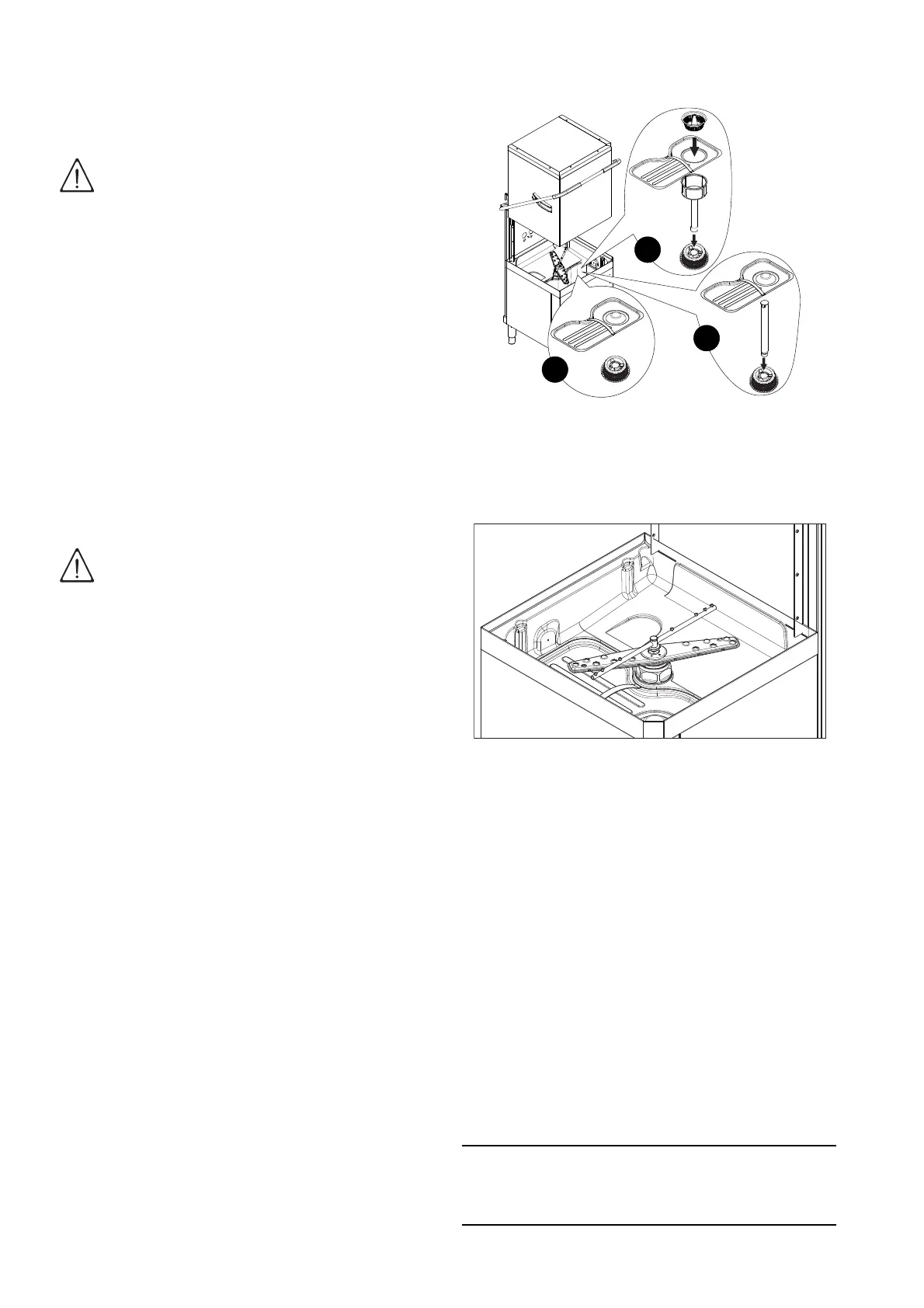

H1.2.2 Arm fitting check

Make sure the upper and lower wash and rinse arms

are correctly fitted (

Figure 18).

H2 Starting

• Open the water supply cocks.

• Turn the main switch of the machine to “I”.

• Press the On/Off key Table 2 (“A” - “Control panel”).

H3 Detergent/rinse-aid dispensers and

settings

If the appliance is connected to a water softener or

osmotic device, contact the detergent supplier for a

specific product.

If the peristaltic dispensers are installed in the

machine, the detergent/ rinse aid dosage is made

automatically according to the desired concentration.

The detergent / rinse aid concentration depends on the

product type and the water supply hardness (check the

features on the product label).

The peristaltic dispensers (detergent and rinse aid)

and the tube inside the rinse aid dispenser require

periodical maintenance (at least once or twice a year)

or after prolonged periods of machine inactivity.

IMPORTANT!

These operations must only be carried

out by specialized technicians pro-

vided with adequate personal protec-

tion equipment (e.g. safety footwear,

gloves, glasses, etc.), tools and suita-

ble ancillary equipment.

IMPORTANT!

The following operations must be car-

ried out by operators provided with

suitable personal protection equipment

(e.g. protective gloves, etc.) with the

machine switched off and cold.

Figure 17 Filters and overflow

Figure 18 Wash and rinse arms

3

B

2

1

2

1

3

4

A

3

1

C

Loading...

Loading...