0410 13

7

D1060

D0455

D1053

Notice

Date Page

05102004

INSTALLATION

MANUAL

7. Installation

Steam and condensate connections

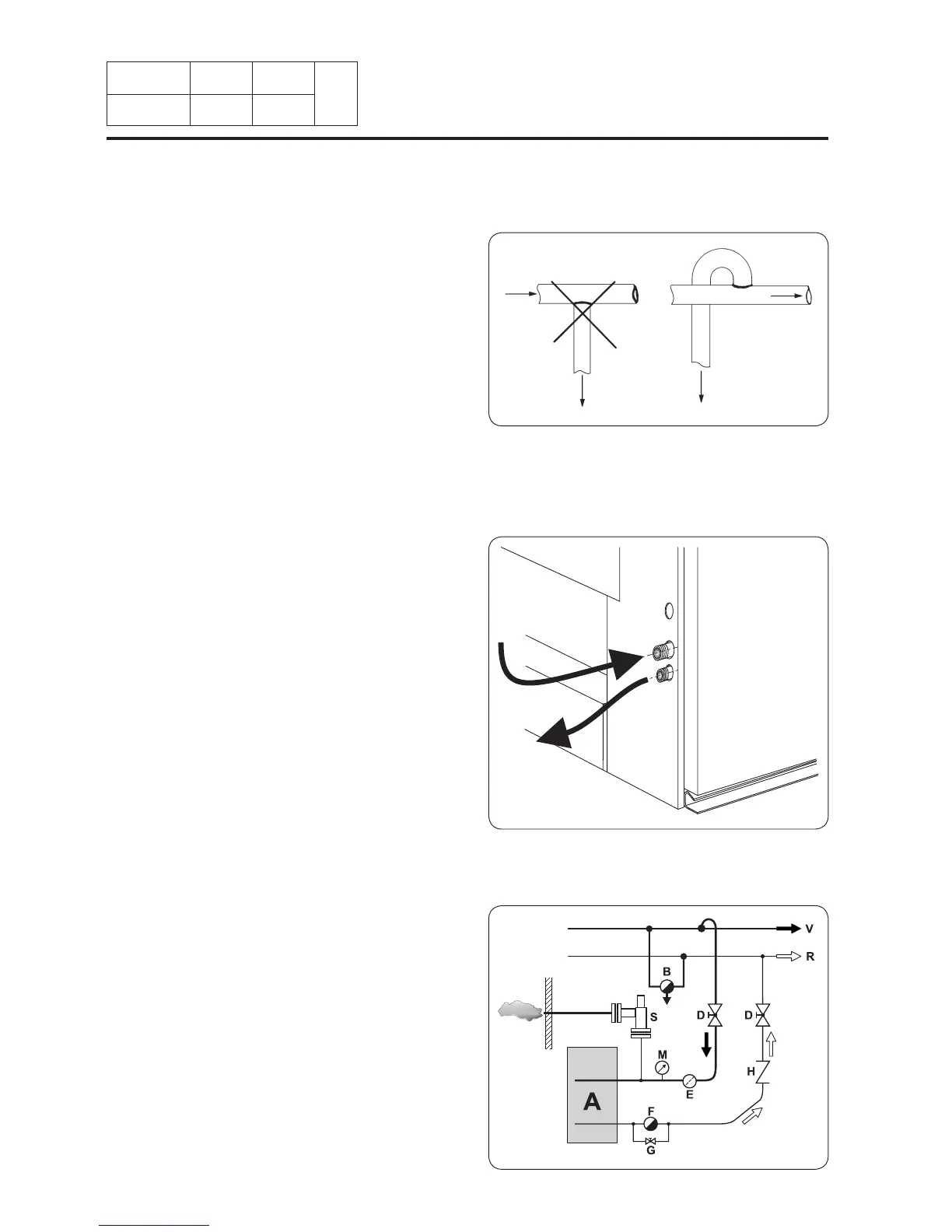

There is always a risk that a certain amount

of water will be carried in steam.

Water is carried in the lower parts of the

supply tubes, and steam in the upper parts.

Make a swan neck branch-T on the main

tube to prevent this water damaging the

machine heating system. This will ensure

that only steam is retrieved without any

condensed water.

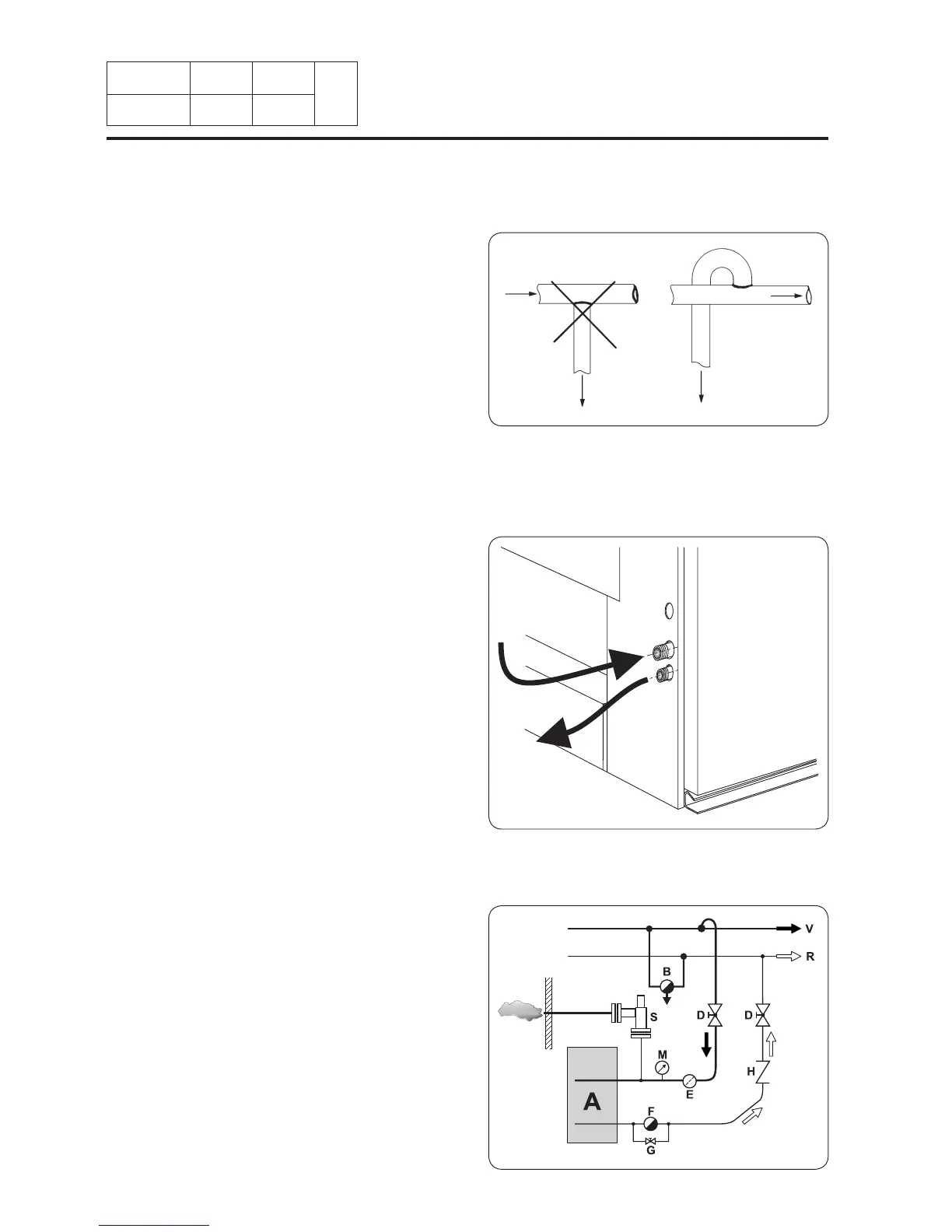

Steam connection DN 20 (3/4" BSP)

The customer must install a line purge, a manually closing valve with handwheel lockable in off

position (do not use a 1/4 turn valve) and a lter on the supply side of the ironer.

The customer must install a safety valve if the boiler used operates at a pressure over the

acceptable vapour of 1000 kPa maxi (10

bar).

Condensate connection DN 10 (3/8"

BSP)

The customer must install a steam trap with

oat closed and incondensibles drainage

device (example : Sarco ref. FT10C - G 3/4"

PN 25 or Gestra ref. UNA15 h - G 3/4" PN

25), a by-pass, a non-return valve and a

manual closing valve lockable in off position.

A

Ironer

B Line trap (supplied by the client)

D The valve is lockable in the closed

position (supplied by the client)

E Filter (supplied by the client)

F Steam trap (supplied by the client)

G By-pass (needle valve) (supplied by

the client)

H Non-return valve (supplied by the

client)

M Pressure gauge (supplied by the

client)

N Thermal insulation for the pipework

(supplied by the client)

R Return of condensates

S Safety valve (supplied by the client)

V Steam inlet (supplied by the client)

Loading...

Loading...