SOI 01.05 FV 29/33 599 36 78-06

COMPONENT REPLACEMENT AND ADJUSTMENT PROCEDURE

REMOVAL

1. Disconnect the power supply cord.

2. Open the door slightly and remove the built in

frame assembly(Ref: to chapter built in frame

assembly removal).

3. Remove the choke cover taking care not to

break clips by inserting an iron plate (thickness

of about 0.5mm) or flat type screw driver to the

gap between the choke cover and door panel

as shown Figure C-4 to free the engaged

parts.

4. Release choke cover from door panel.

5. Now choke cover is free.

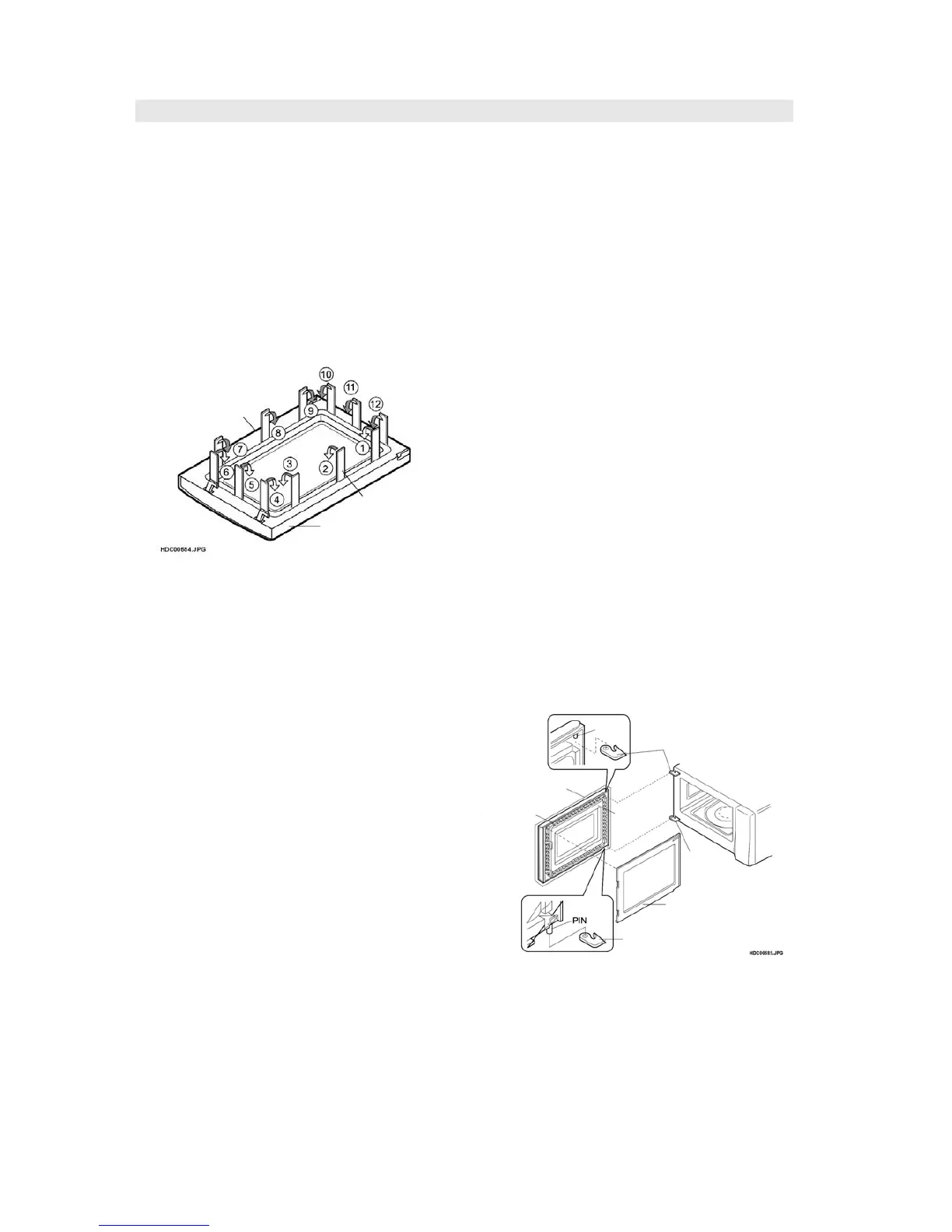

Figure C-4. Door Disassembly

6. Release two (2) pins of door panel from two (2)

holes of upper and lower oven hinges by lifting

up.

7. Remove door assy by removing screws (4).

8. Release door panel from tabs of door frame and

remove door frame.

9. Now, door panel with inner sealer film is free.

10.Tear inner sealer film from door panel.

11.Now, door panel is free.

12.Slide latch head upward and remove it from

door frame with releasing latch spring from door

frame and latch head.

13.Now, latch head and latch spring are free.

RE-INSTALL

1. Re-install latch spring to the head. Re-install

latch spring to the door frame. Re-install latch

head to the door frame.

2. Re-install door panel to door frame by fitting tabs

of door frame to holes of door panel.

3. Put sealer film on door panel. Refer to “Inner

Sealer Film” and figure C-6, on how to handle

the new film.

4. Catch two (2) pins of door panel on two (2) hole

of upper and lower oven hinges.

5. Re-install choke cover to door panel by pushing.

Note: After any service to the door;

(A) Make sure that monitored latch switch, stop

switch and monitor switch are operating

properly. (Refer to chapter “Test

Procedures , Switch Test page 17”.).

(B) An approved microwave survey meter

should be used to assure compliance with

proper microwave radiation emission

limitation standards.

After any service, make sure of the following :

1. Door latch heads smoothly catch latch hook

through latch holes and that latch head goes

through center of latch hole.

2. Deviation of door alignment from horizontal line

of cavity face plate is to be less than 1.0mm.

3. Door is positioned with its face pressed toward

cavity face plate.

4. Check for microwave leakage around door with

an approved microwave survey meter. (Refer to

Microwave Measurement Procedure.)

Note: The door on a microwave oven is

designed to act as an electronic seal

preventing the leakage of microwave

energy from oven cavity during

cook cycle. This function does not require

the door be air-tight, moisture

(condensation)-tight or light-tight.

Therefore, occasional appearance

of moisture, light or sensing of gentle

warm air movement around oven door is

not abnormal and does not indicate

leakage of microwave energy from the

oven cavity.

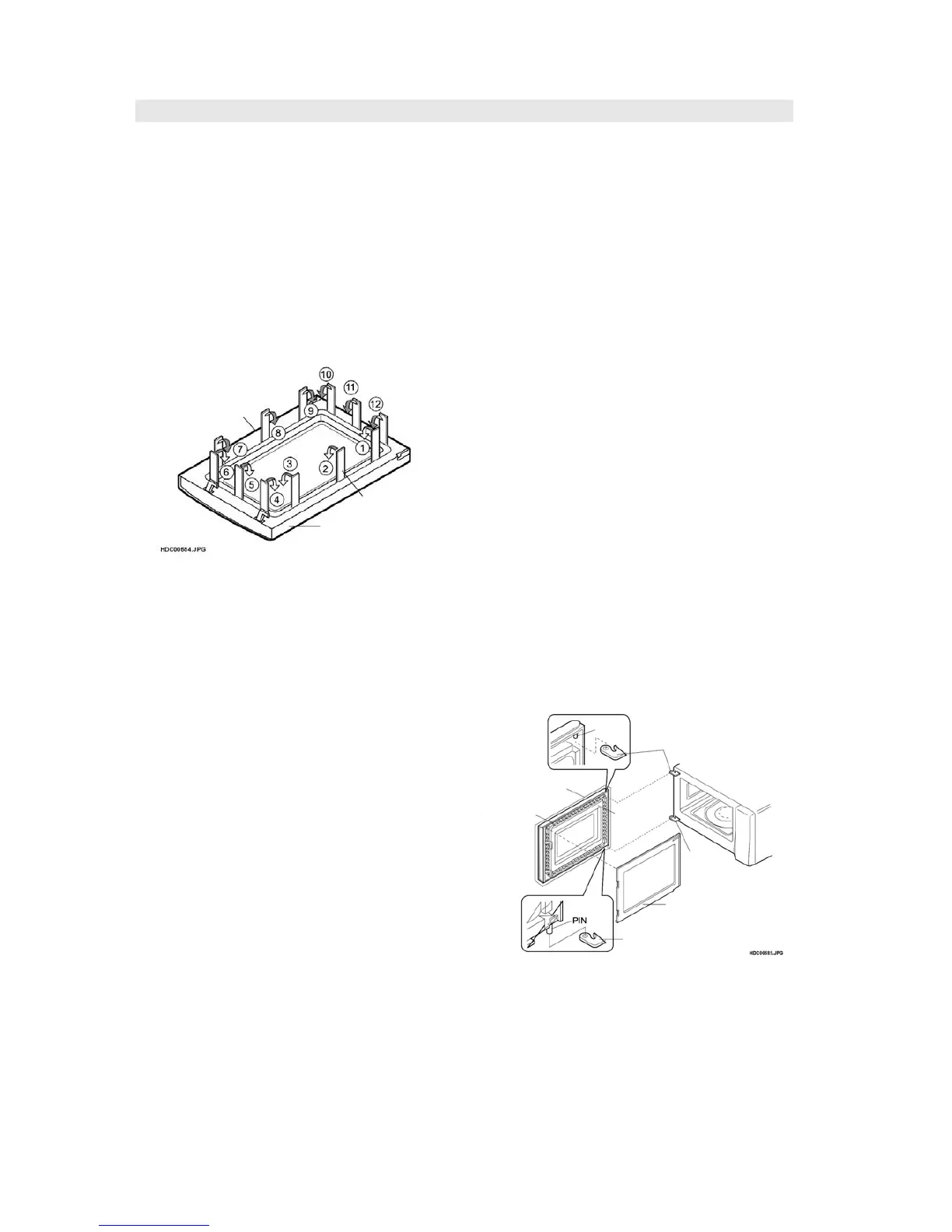

Figure C-5. Door Replacement

NOTE: When carrying out any repair to the

door, do not bend or warp the slit

choke (tabs on the door panel

assembly) to prevent microwave

leakage.

Choke Cover

Putty Knife

Door Frame

PIN

UPPER

OVEN HINGE

DOOR SUB

ASSEMBLY

DOOR

PANEL

SLIT CHOCHE

CHOKE COVER

LOWER

OVEN

HINGE

LOWER

OVEN HINGE

Loading...

Loading...