12

Error codes

In case of a malfunction, an error code is indicated on the digital multifunction display 54 and the corresponding error description

appears on the LCD display 50. As long as an error code is indicated, welding operation is not possible.

Code lock function

The lock function in menu Extras is secured with a code lock. A three-digit code must be entered before the lock function can be

changed. Only after the correct code is entered, the lock function can be altered. After leving the menu, a new code number can

be set or the old code number is acknowledged. Code "000" is the default (factory setting) number.

Procedure:

switch to menu Extras, lock function

pressing button 44 (minus) or 48 (plus) question „change parameter ?“ is displayed

acknowledge with button 51 (up)

set three-digit code number with button 44 (minus), 48 (plus) or encoder 53

acknowledge the code number with button 51 (up)

set desired lock function number with buttons 44 (minus) or 48 (plus)

leave menu with button 46 (END)

if requested, set a new code number with buttons 44 (minus), 48 (plus) or encoder 53

acknowledge the code number with button 51 (up)

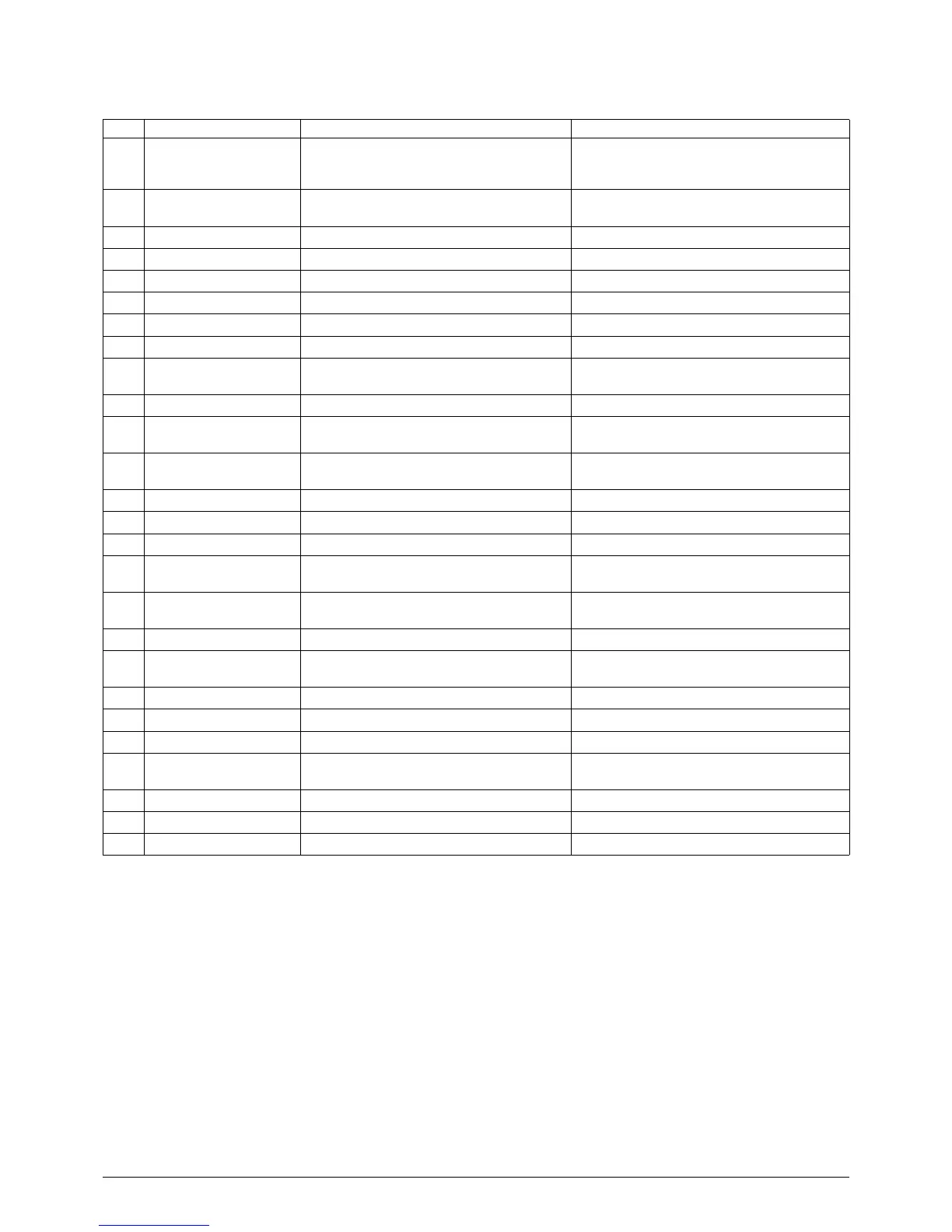

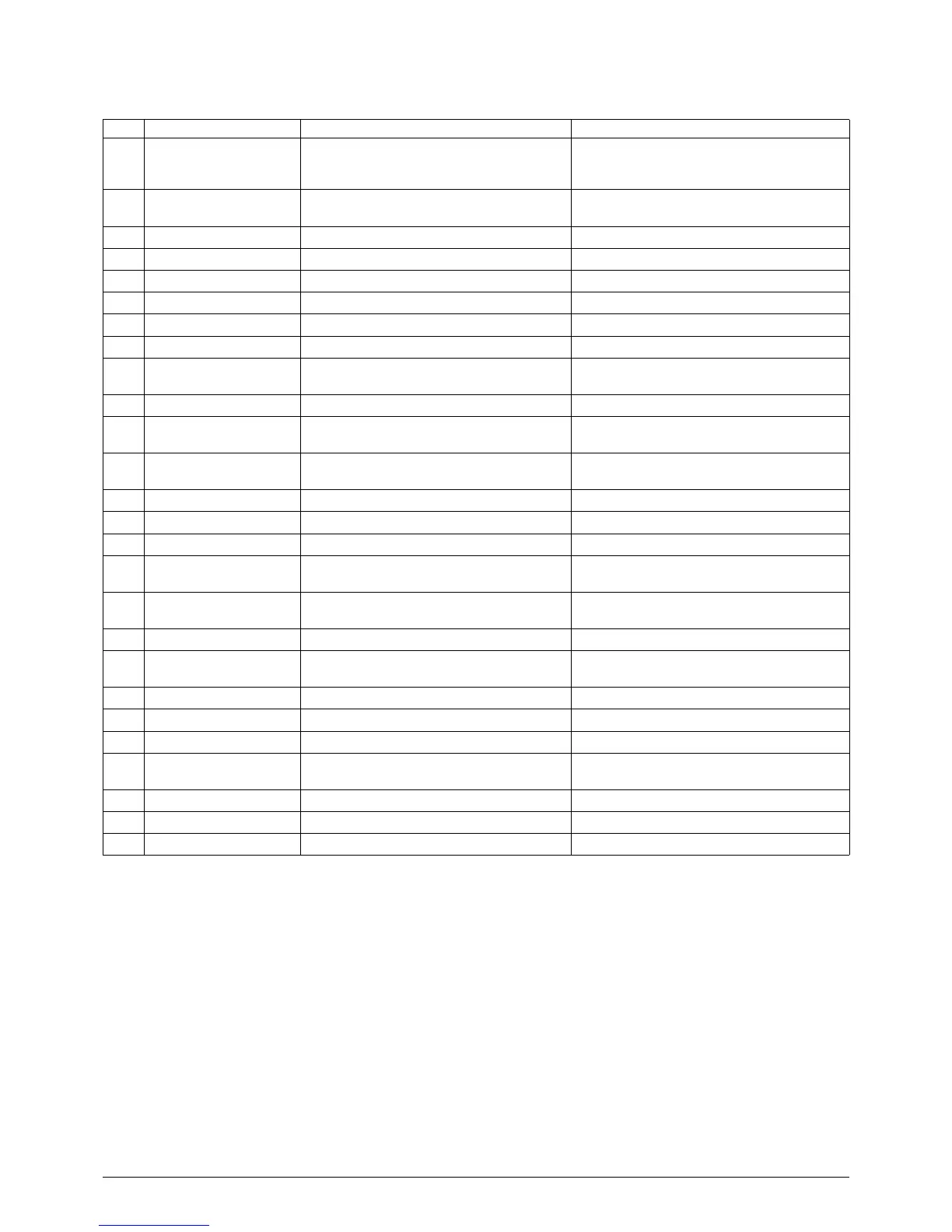

Code Error description Remark Remedy

E00 no Prog No welding parameters for the selected

material-wire-gas combination (no sensible

combination)

Choose a different material-wire-gas

combination

E01 Thermal overload The system has been overheated Allow the system to cool down in standby;

check the ventilation

E02 Mains overvoltage Mains voltage too high Check mains voltage

E03 Overcurrent Output current too high Notify service technician

E04 Air-cooling error Flow rate of air too low Clean the air intake 9; check fan

E05 Faulty cooling circuit No or too little flow rate of water Check level of cooling liquid and coolant filter

E06 Overvoltage Output voltage too high Notify service

E07 EEProm checksum error Adjustment data faulty or not available Switch system off and then on again

E08 Wire feed / tacho Current input from feed motor too high

No tacho signal available

Blow out torch package with compressed air

and check wire feed unit

E09 Error v/a measuring Faulty current / voltage measuring systems Notify service

E10 Torch socket / cable Faulty torch switch cable or torch switch

socket

Check torch

E11 Remote control socket Faulty remote control or socket of remote

control

Check remote control

E12 Communication process Defective communication CAN-Bus (process) Switch system off and then on again

E13 Error, temperature sensor Thermo sensor not operative Notify service

E14 Supply voltage Internal supply voltage too low Check mains voltages

E16 Overcurrent protection 1 Allowable maximum power supply of power

unit 1 too high

Notify service

E18 Overload protection Safety switch device for protection of

electrical components

Allow the system to cool down in standby

E20 Overvoltage secondary Output voltage too high Notify service

E21 Output voltage / current Power unit delivers voltage / current without

drive

Notify service

E22 Mains undervoltage 1 Mains voltage at power unit 1 too low Check mains voltages

E23 Mains overvoltage Mains voltage too high Check mains voltages

E24 Overcurrent protection 2 Power supply of power unit 2 too high Notify service

E25 Power-module detection Power unit not being recognized or unallowa-

ble combination of power units

Notify service

E27 No program (DSP) Welding programs faulty or not available Notify service

E30 Mains undervoltage 2 Mains voltage at power unit 2 too low Check mains voltages

E31 Communication error Faulty communication CAN-Bus (master) Switch system off and then on again

Loading...

Loading...