6

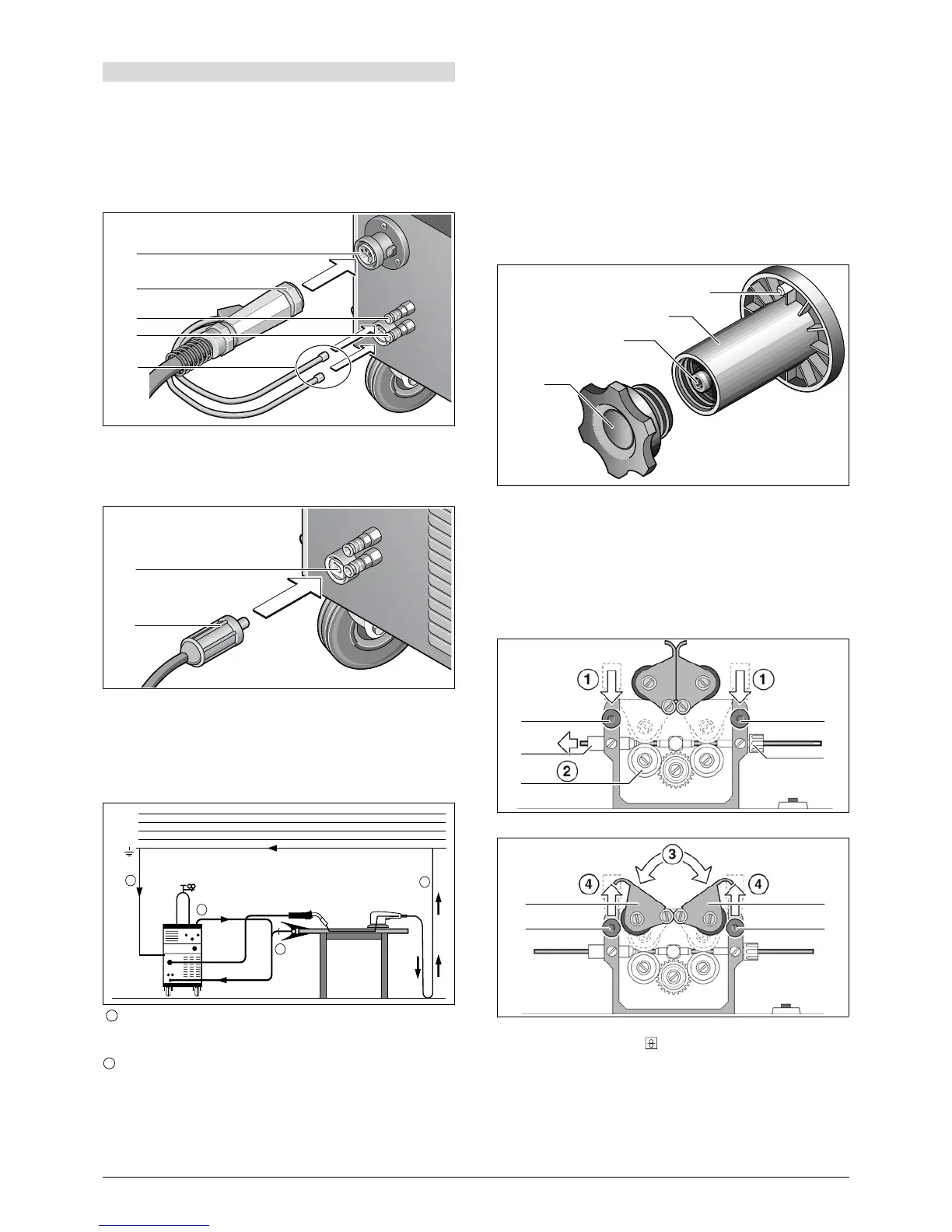

Torch connection

Plug in the centralplug 17 of the torch 1 into the central socket

16. At machines with water-cooling: Connect additionally the

waterconnections 20 of the torch with the sockets 18 and 19.

Please keep attention at the colour labelling.

Red = water back-run 19

Blue = water fore-run 18

How to connect the ground cable

Connect the ground cable 22 at the groundconnection 14 and

fasten it turning to right and connect the ground clamp 13 to

the workpiece or at the welding table.

How to connect the ground clamp

Fasten the ground clamp 13 near the welding location, this

avoids that the current will flow trough machineparts or con

-

trols.

Please keep attention that the connections between ground

clamp and workpiece is constant.

Do not place the ground clamp on the welding machine or

gas cylinder, otherwise welding current is conducted via

the protective conductors and will destroy them.

Connect the ground clamp tightly to the welding bench or

to the workpiece.

How to connect at the mains

Plug in the plug into the mains socket. The fusing should be

corresponding to the technical data.

How to insert the wirespool

Open the lid at the machine or at the wire-feed case 2 and

screw off the nut 26 from the wire-coil pick-up 24.

Put on the wire coil at the wire-coil pick-up and pay attention

that the tappet is well insert at the coil 23.

By use of small wire coils please use the adapter.

Adjust the brake 25 by releasing the torch button the wire coil

do not continue to turn.

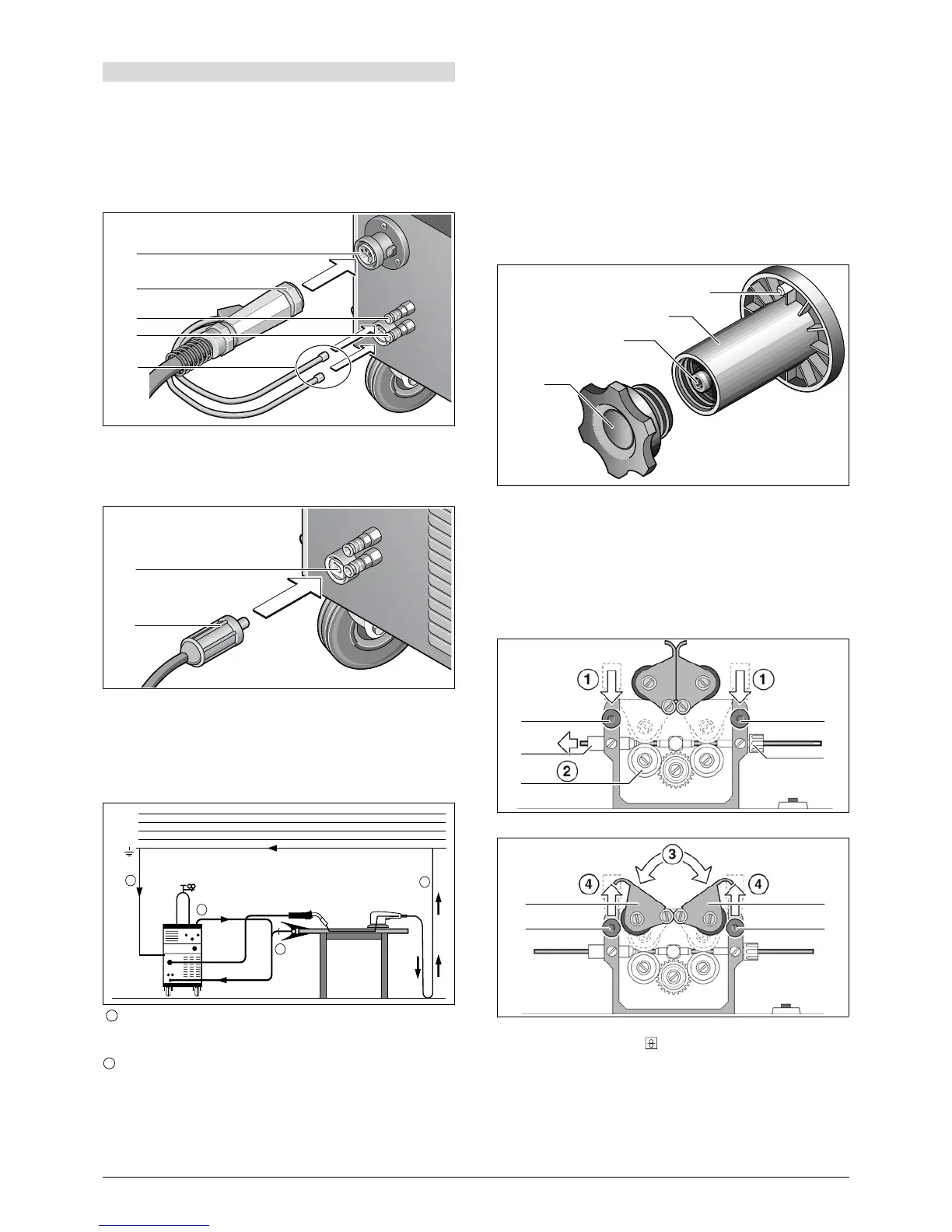

Insert of the wire electrode

Screw out the contact tip at the torch 1.

Open the lid at the unit or at the wire feeder 2.

The diameter of the wire should correspond to the diameter of

the feeding rolls. This is readable on the front at the built in

feeding roll 29.

Lift the lever 27 and thread in the wire electrode trough the in-

let nozzle 28 and the central connection 16.

Close the lever 30 and fasten it with the sweep levers 27.

Switch on machine at main switch 11, stretch torch cable and

press button wire insert

on operating panel. Adjust the

pressure at the modulation screws 27 that the wire-feed rolls

29 even still are turning by holding the wire coil. The wire

should not be clamped or deformed.

10 Before operation

16

17

18

19

20

14

22

2

1

1

L

1

(R)

L

2

(S)

L

3

(T)

N(MP)

PE

1

1

2

23

24

25

26

29

27

28

16

27

30 30

27

27

Loading...

Loading...