9

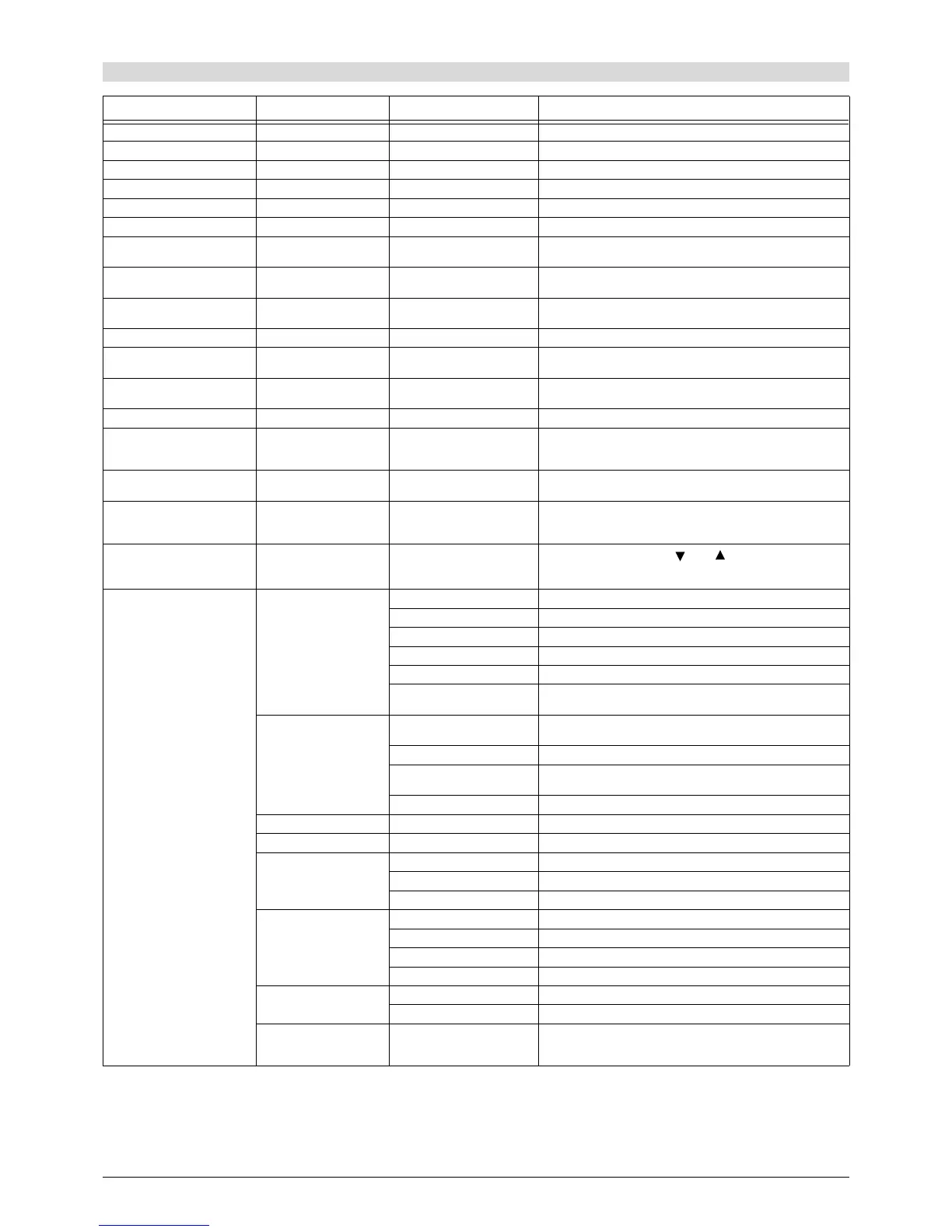

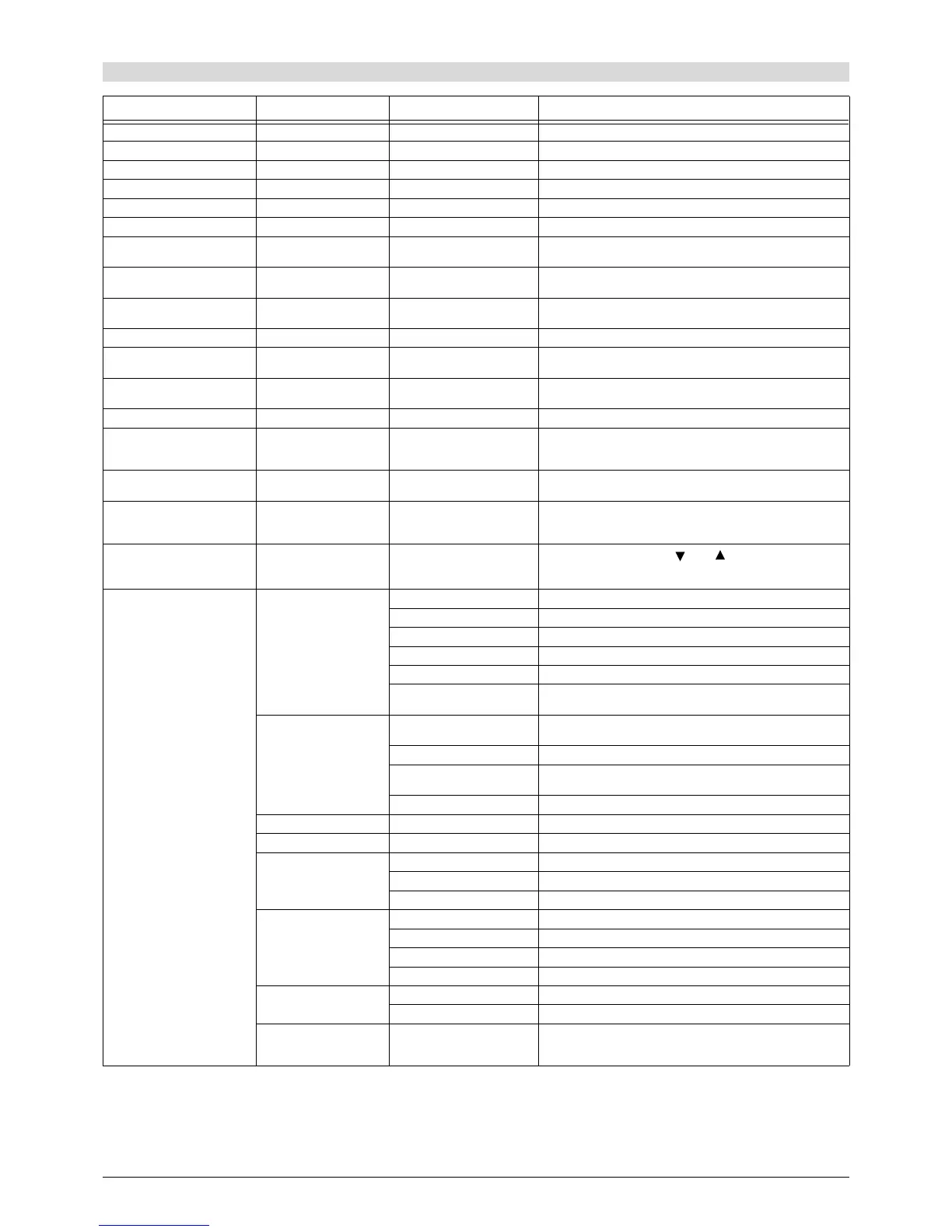

12 Menu Structure

Main Level Level 1 Level 2 Remark

Gas pre-flow 0 – 10 sec.; not in electrode mode

Start current 20 % – 200 % of the welding current

Start current time 0 – 10 sec.; not in 4-stroke mode

Twin pulse frequency 0,5 – 5 Hz; only in Twinpulse mode

Twin pulse current change 5 – 50 % of the welding current; only in Twinpulse mode

Twin pulse relation 20 % – 80 %; only in Twinpulse mode

Welding current Adjustment range depends on the selected material-wire-

gas combination

Downslope 10 – 990 A/sec.; not in electrode mode, only when downs-

lope = on

Final current 10 % – 100 % of the welding current; not in electrode mode,

only when slope = on or in 4-stroke

Final current time 0 – 10 sec.; not in electrode mode, only for slope = on

Wire burnback time 20 % – 300 % of the programmed value; not in electrode

mode

Gas post-flow 20 % – 200 % of the programmed value; not in electrode

mode

Arc length correction 60 % – 140 % of the programmed value

Inductor effect 20 % – 200 % of the programmed value; only in normal

mode (short arc)

+/- 40% in manual mode (see “Manual mode” on page 11)

Arc dynamic 0 % – 100 % of the programmed value; only in electrode

mode

Job selection, indication of

set and job name

Set and job name are indicated only in Tiptronic mode

upon actuation of the “TT Enter” push-button 47 or the “Tip-

tronic” push-button 49

Edit mode for set and

job name

Move the cursor with the and push-buttons 51;

change the character with the pushbuttons 48 (+) and 44 (-

)

Extras 1Machine data Operating system Master Version number, operating system Master

Operating system Process Version number, operating system process

Operating system DMRs Version number, motor assembly (-ies)

Welding program version Version number, welding programs

Operating hour counter Indication of the welding duration in h, min, sec

Configuration Machine type and the recognized power module (with max.

current ) are indicated alternately

2 Diagnosis Last error message Indication of the last three error messages from the error

memory (0 = last error, 2 = oldest error)

Module temperatures Temperatures of the power modules in °C

Operating voltages Indication of the operating voltages (15 V / 24 V) of the

E-assembly DP-MAPRO

Flow rate, cooling unit Indication of the coolant flow rate in l/min

3 Language Selection of the menu language

4 Display contrast Contrast setting of the LCD display

5 Mode cooling system 0 normal cooling unit switches on, as soon as an arc is ignited

1 on cooling unit runs constantly

2 off cooling unit is deactivated

6 Lock function 0 All free

1 Welding current, mode and Tiptronic on/off free

2 Tiptronic on/off, job selection free

3 All locked except menu selection, gas and pump test

7 Arc lenght control voltage correct arc lenght with rotary pulse encoder 58

wire correct wire speed with rotary pulse encoder 58

8 Robot interface Menu item is only visible when the machine is equipped

with a robot interface (further details about setup/configura

-

tion see operation manual INT)

Loading...

Loading...