16

Pulsed arc applications

The main application for pulsed arcs is unalloyed steels within

the performance range of the transition arc. At the lower end

of the performance range the pulsed arc cannot fully replace

the short-circuiting arc. The reason here is the continuous arc

that occurs in the primary current phase. This phenomenon

does not exist with the short-circuiting arc. An exception to

this is when welding aluminium and aluminium alloys. Nor

-

mally, these materials can only be reliably welded using a

pulsed arc. In the upper performance range, the pulsed arc is

preferable to the sprayer arc, in particular for welding alumin-

ium materials and high-alloy steels.

Please keep attention to the current safety regulations at all

care and maintenance works.

The machine requires minimum of care and maintenance.

Only a few items should be checked to ensure a trouble free

long term operation:

– Check the mains plug, mains cable, and the welding

torch as well as the ground connection for damage from

time to time.

– Once or twice a year please clean the machine with dry

low compressed air. Switch off the machine and pull out

the plug first. Open the case of the machine and clean

also inside - please avoid to blow directly onto electronic

parts – they could be damaged.

15 Care and maintenance

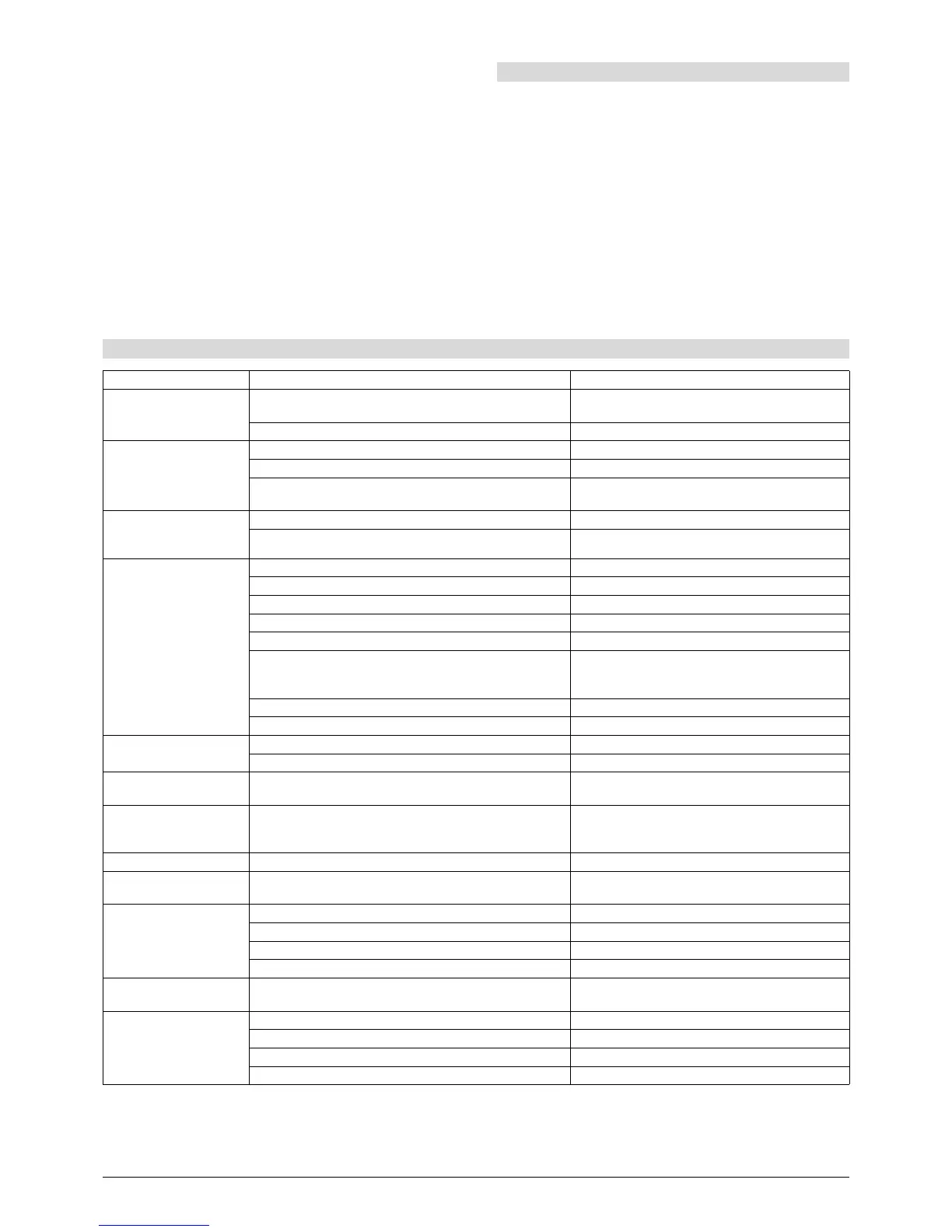

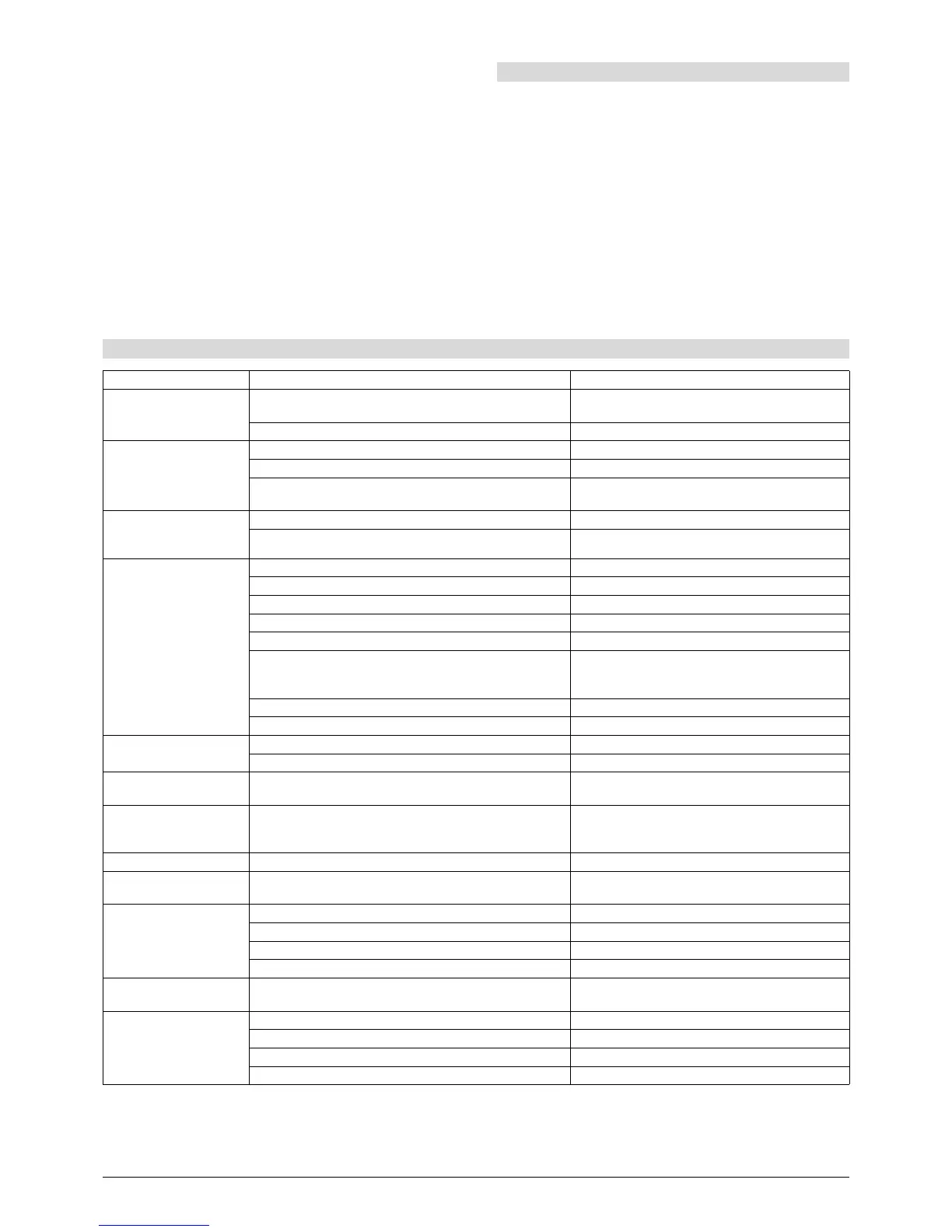

16 Troubleshooting guide

Symptom Cause Remedy

Torch too hot Insufficient coolant through flow due to pollution into

coolant

Swill the waterhoses of the torch in opposite

direction

Contact tip is not tight Check it

No function when torch

button is pressed

Nut of the torch hose is not tight Tighten it

No connection of the control cable in the torch hose Check and change if necessary

Overload of the unit and thermal protection is in

function

Allow unit to cool down at no load

Irregular wire feeding or

wire welds to the con

-

tact tip

Wire electrode is tight at the spool Check and change if necessary

Burr at the wire beginning Cut the wire beginning again

Irregular wire feeding or

no wire feeding

Wrong contact pressure at the wire-feed rolls Adjust it as described in the manual

Torch defect Check and change if necessary

No brass pipe in the central connection or is dirty Install or clean the brass pipe

Bad quality of welding wire Check and change if necessary

Rust formation at the welding wire Check and change if necessary

Torch liner is dirty inside Disconnect the torch from the machine, screw

off the contact tip and clean the liner with com

-

pressed air

Torch liner is dejected Check and change if necessary

Motor brake adjusted to strong Adjust as described in the manual

Unit switches off Duty cycle overloaded Allow the machine to cool down

To less cooling of unit parts Check the air in and outlet

Cooler or hoses defect

or pump is damaged

Freezed systems due to less anti freezer liquid Contact the nearest service facility

Arc or short circuit

between contact tip

and gas nozzle

Spatter built up inside the gas nozzle Remove it with special pliers

Unstable arc Wrong diameter of contact tip or worn out Change contact tip

The DP20 operating

panel is completely dark

Phase missing Check the unit at another power outlet. Check

power cable and mains fuses/circuit breakers

No shielded gas Gas cylinder empty Replace it

Defect torch Check and replace it

Pressure reducer dirty or defect Check and replace it

Valve of gas cylinder defect Replace the gas cylinder

Shielded gas switches

not off

Valve of gas cylinder dirty or does not close Remove torch and pressure reducer and clean

it with compressed air

Not sufficient shielded

gas

Wrong adjusted quantity of shielded gas Adjust right as described in the manual

Dirty pressure reducer Check valve

Torch, gashose blocked or not air-tight Check and change if necessary

Shielded gas is blow away from draught Avoid draught

Loading...

Loading...