6.2.Production operation

The production operation is designed to sharpen several tools with the same diameter.

To program the production operation, go to the LCD menu screen. Select the program: 2. Production (Pro-

ducción) (see fig.7), to set parameters of the production operation, by pressing the menu selector. You will

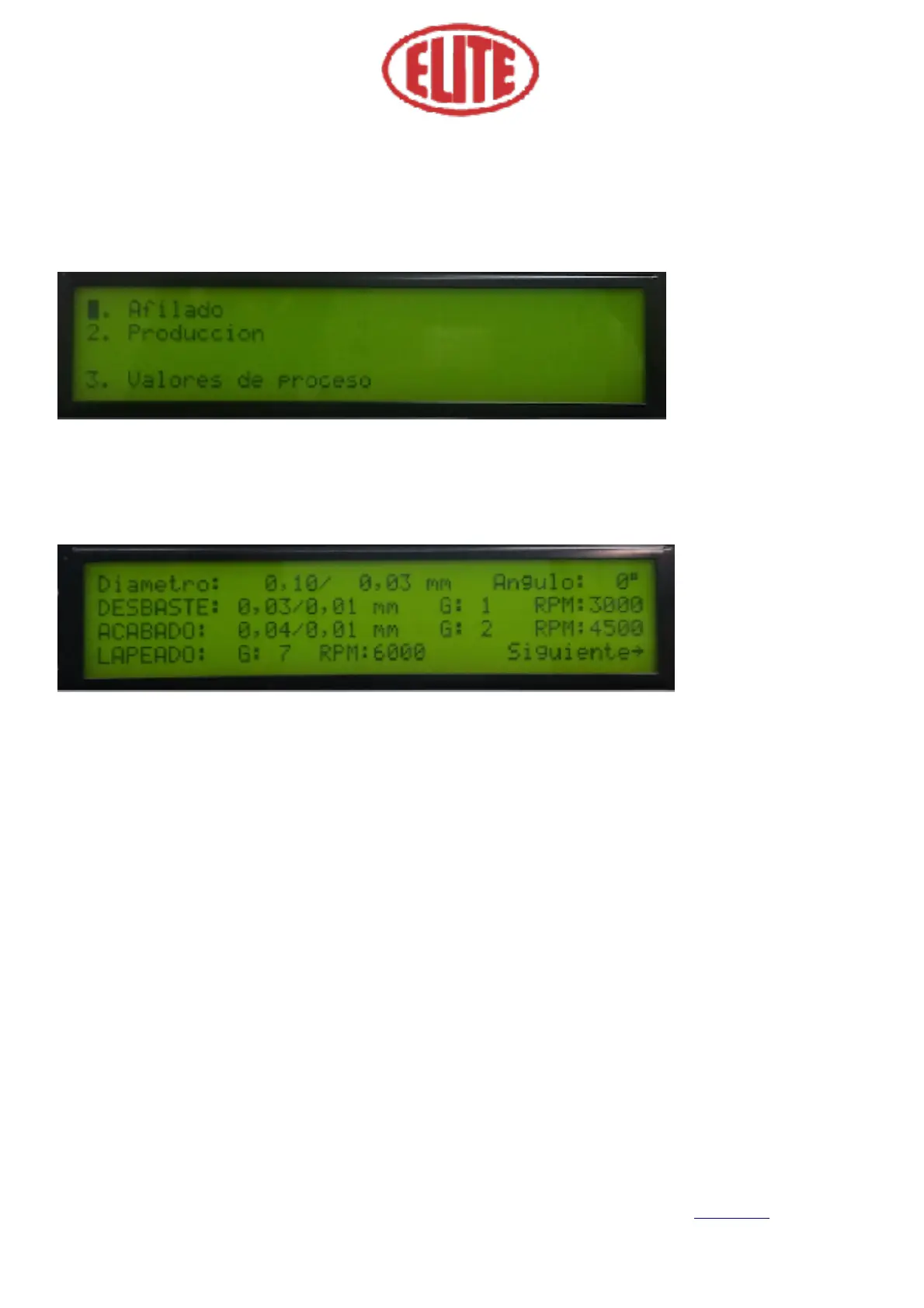

then see the following screen (see Figure 8).

• 1. Diameter (Diámetro): The first parameter corresponds to the actual measured diameter of the circular

saw (Fig. 8 See eg 0.10) and the second; To the desired sawing diameter (Fig. 8 See i.e.: 0.03).

• 2. Angle (Ángulo): In this parameter you must enter the selected angle in the divider head (Fig. 8 See i.e.:

0º)

• 3. Roughing (Desbaste): is the boot process. The first numeric value indicates the total roughing, which is

calculated automatically by the program. The operator must only enter the values required for the partial

roughing (Fig. 8 See i.e.: 0.01) and for the grinding wheel speed expressed in RPM (revolutions per

minute).

• 4. Finishing (Acabado): Once the roughing process is finished, the finishing process is started. In the first

box the amount of total finishing is shown (Fig. 8 See i.e.: 0,04), in the second box the amount of partial

finishing (Fig. 8 See i.e.: 0,01). Then, the option of the partial finishing by number of turns appears (Fig. 8

See G 2) and wheel speed option for finish expressed in RPM (Fig. 8 See RPM 4500). Select the parameters

required for the program desired by the operator.

Loading...

Loading...