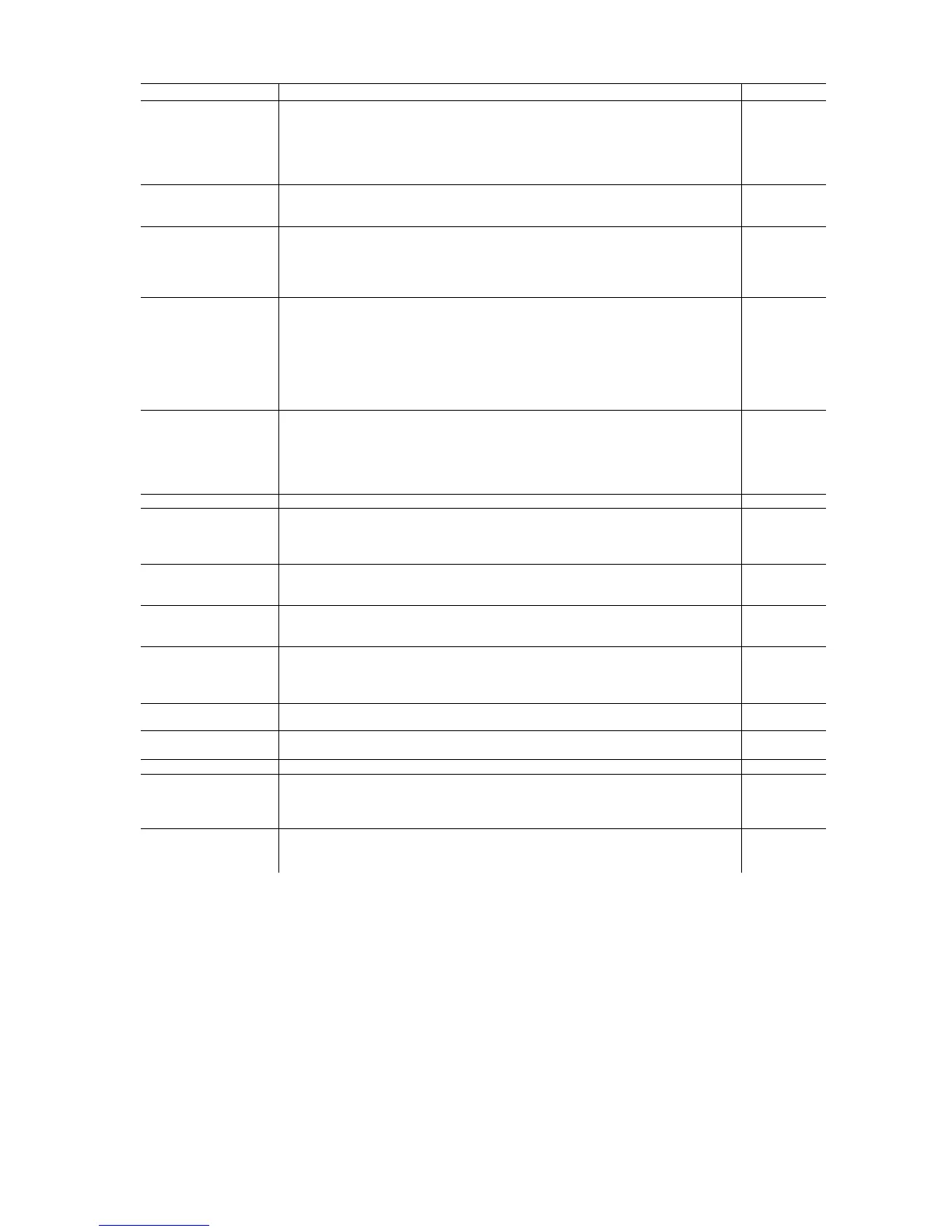

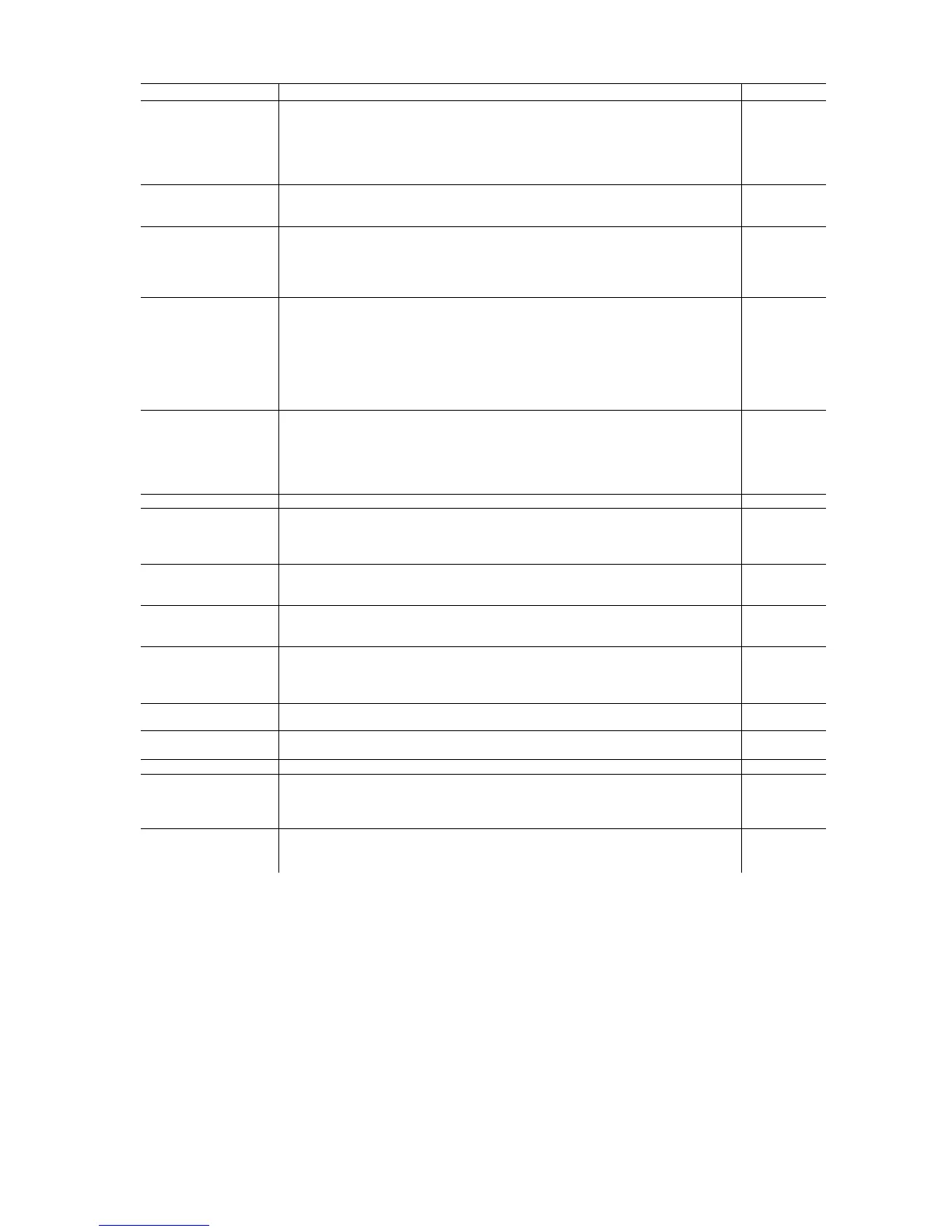

T R O U B L E S H O O T I N G

Condition Cause

See p ag e (s )

Needle thread breaks 1. The needle is not threaded properly. 20

2. The needle thread tension is too tight. 10

3. The needle is bent or blunt. 12

4. The needle is not inserted correctly. 12

5. The thread is either too heavy or too fine for the needle. 12

6. The thread is tangled around spool. 20

Bobbin thread breaks 1. The bobbin thread is not threaded correctly in the bobbin case. 19

2. Lint has collected in the bobbin case. 25-26

3. The bobbin is damaged and does not turn smoothly. Change bobbin.

Needle breaks 1. The needle is not inserted correctly. 12

2. The needle is bent or blunt. 12

3. The needle clamp screw is loose. 12

4. The needle thread tension is too tight. 10

5. The needle is too fine for the fabric being sewn. 12-13

Skipped stitches 1. The needle is not inserted correctly. 12

2. The needle is bent or blunt. 12

3. The needle and/or the thread are not suitable for the fabric being sewn. 12-13

4. A stretch needle is not being used for sewing stretch, very fine and

synthetic fabrics. 12-13

5. The needle thread is not threaded properly. 20

6. The foot pressure dial is not adjusted correctly. 8

7. The wrong needle is being used. 12-13

Seam puckering 1. The needle thread tension is too tight. 10

2. The machine is not threaded correctly. 19-20

3. The needle is too large for the fabric being sewn. 12

4. The stitch length is too long for the fabric. 16

5. The foot pressure dial is not adjusted correctly. 8

Place light weight stabilizer under lightweight fabrics.

Slipping fabric 1. The foot pressure dial is not adjusted correctly. 8

Fabric does not feed 1. The feed dog is packed with lint. 25-26

smoothly 2. The foot pressure dial is not adjusted correctly. 8

3. The stitches are too short. 16

4. The feed dog was not raised after being lowered. 7

Gathering 1. The needle thread tension is too tight. 10

2. The needle is either too large or too small for the thread. 12

3. The stitches are too long for fabric weight. 16

Machine does not work 1. The machine is not plugged in. 11

2. A thread is caught in the hook area. 25-26

3. The bobbin winder spindle is still in the winding position. 18

Stitches are distorted 1. The fine adjustment screw is not adjusted properly. 7

2. The needle thread tension is too tight. 10

3. The stitch length is not suitable for the fabric being sewn. 16

4. Use interfacing for fine or stretch fabrics. Use stabilizer.

Buttonholes do not 1. Interfacing is not being used with fabrics. 23

work 2. Buttonhole lever is not pulled down. 24

Noisy operation 1. Threads have been caught in the hook area. 25-26

2. Lint has built up in the bobbin case or hook area. 25-26

Fabric layers shift 1. The foot pressure dial is not adjusted correctly. 8

Machine stops and Lo 1. Threads have been caught in the hook area. 25-26

appears 2. Lint has built up in the bobbin case or hook area. 25-26

3. The machine is not threaded correctly. 19-20

4. The fabric is too heavy. 12

Machine stops and E1 1. Machine needs servicing. Contact your

appears

authorized Elna

service center.

You may hear a faint humming sound coming from your machine

’

s internal motors. This is normal and no

cause for concern.

Loading...

Loading...