October 2015

Service Instructions

VA001-196-30 Rev. 1

1

Section 1: Introduction

Introduction

Section 1: Introduction

1�1 General Service Information

1�1�1 This service procedure is offered as a guide to enable general maintenance to be

performed on Bettis CBB double-acting series actuators. The following is a list of

general CBB model numbers.

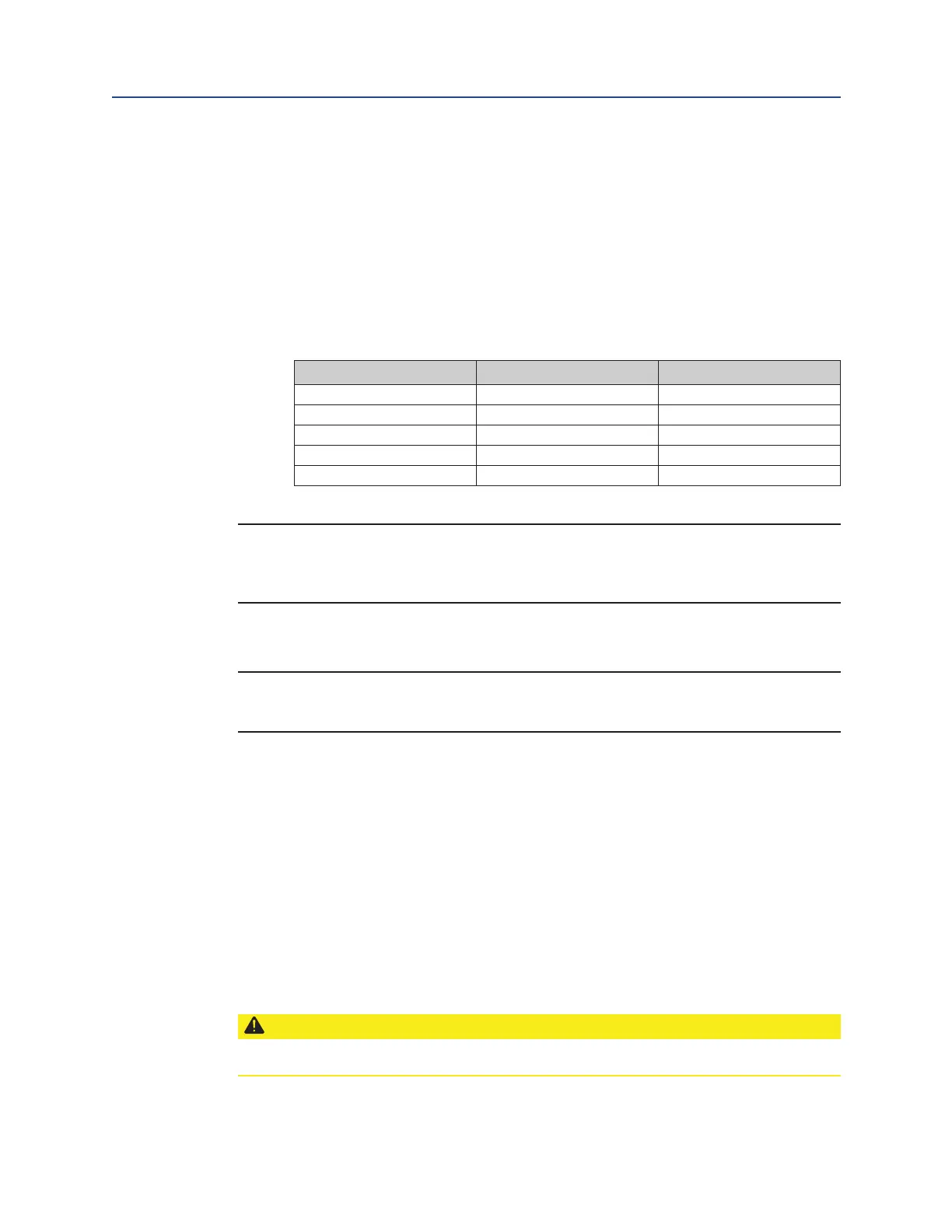

Table 1� CBB Model Numbers

MODEL (1) MODEL (2) MODEL (3)

315 315-M3 315-M3HW

420 420-M3 420-M3HW

520 520-M3 520-M3HW

525 525-M3 525-M3HW

725 725-M3 725-M3HW

(1)Alsoincludesactuatormodelswith–10and–11asasufx

NOTE:

Whentheactuatormodelnumberhas“-S”asasufxthentheactuatorisspecialandmay

have some differences that may not be included in this procedure.

1�1�2 Normalrecommendedserviceintervalforthisactuatorseriesisveyears.

NOTE:

Storage time is counted as part of the service interval.

1�1�3 This procedure is applicable with the understanding that all electrical power and

pneumatic pressure has been removed from the actuator.

1�1�4 Remove all piping and mounted accessories that will interfere with the module(s)

that are to be worked on.

1�1�5 This procedure should only be implemented by a technically competent technician

who should take care to observe good workmanship practices.

1�1�6 Numbers in parentheses, ( ) indicate the bubble number (reference number) used

on the Bettis assembly drawing and actuator parts list.

1�1�7 When removing seals from seal grooves, use a commercial seal removing tool or a

small screwdriver with sharp corners rounded off.

1�1�8 Use a non-hardening thread sealant on all pipe threads.

CAUTION: FOLLOW MANUFACTURER'S INSTRUCTIONS

Apply the thread sealant per the manufacturer’s instructions.

1�1�9 Emerson recommends that disassembly of the actuator should be done in a clean

area on a workbench.

Loading...

Loading...