October 2015

Service Instructions

VA001-196-30 Rev. 1

3

Section 1: Introduction

Introduction

1�4 Bettis Actuator Reference Materials

1�4�1 CBBXXX Assembly Drawing use part number VA001-005-72-4.

1�4�2 CBBXXX-M3HW Assembly Drawing use part number VA001-005-73-3.

1�5 Service Support Items

1�5�1 Bettis service kit

1�5�2 Commercial leak testing solution

1�5�3 Non-hardening thread sealant

1�6 Lubrication Requirements

1�6�1 The actuator should be relubricated at the beginning of each service interval using

the following recommended lubricants.

NOTE:

Lubricants other than those listed in steps 1.6.2 should not be used without prior written

approval of Emerson product engineering. The lubricant item number on some assembly

drawings is item (5) while the Bettis service kits lubricant item number is item number (500).

1�6�2 Alltemperatureservices(-50°Fto+350°F)/(-45.5°Cto176.6°C)useBettisESL-5

lubricant. ESL-5 lubricant is contained in the Bettis Module Service Kit in tubes and

the tubes are marked ESL-4, 5 and 10 lubricant.

1�7 General Tool Information

1�7�1 AllthreadsonCBBSeriesactuatorsareInchUniedandNPT.

1�7�2 Alltools/HexagonsareAmericanStandardinch.Twoadjustablewrenches,Allen

wrench set, small standard screwdriver with sharp edges rounded off, medium size

standardscrewdriver,diagonalcuttingpliers,externalsnapringpliers,atle,drive

ratchet / deep well socket set and torque wrench (up to 2,000 lbf-in / 226 N-m).

1�8 Actuator Weight

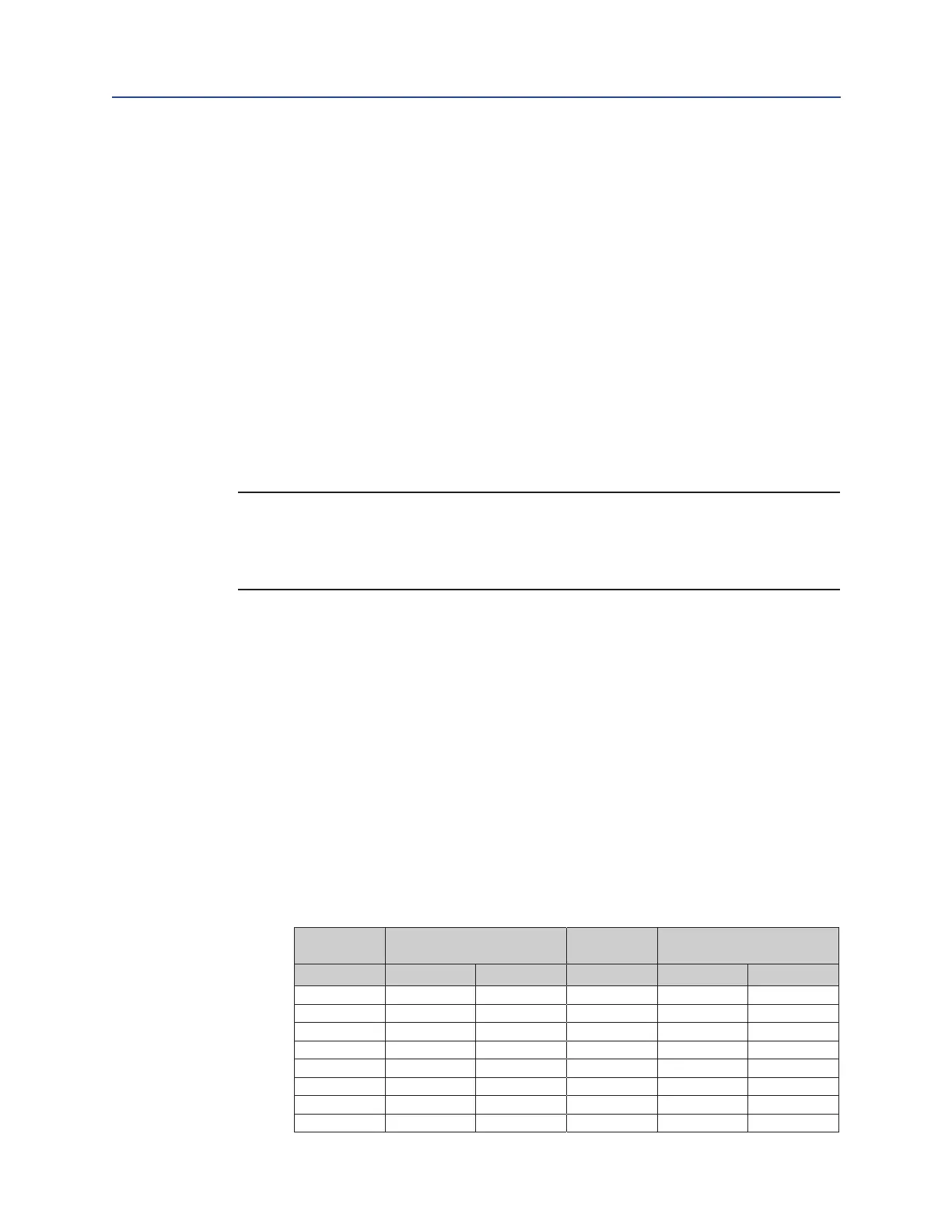

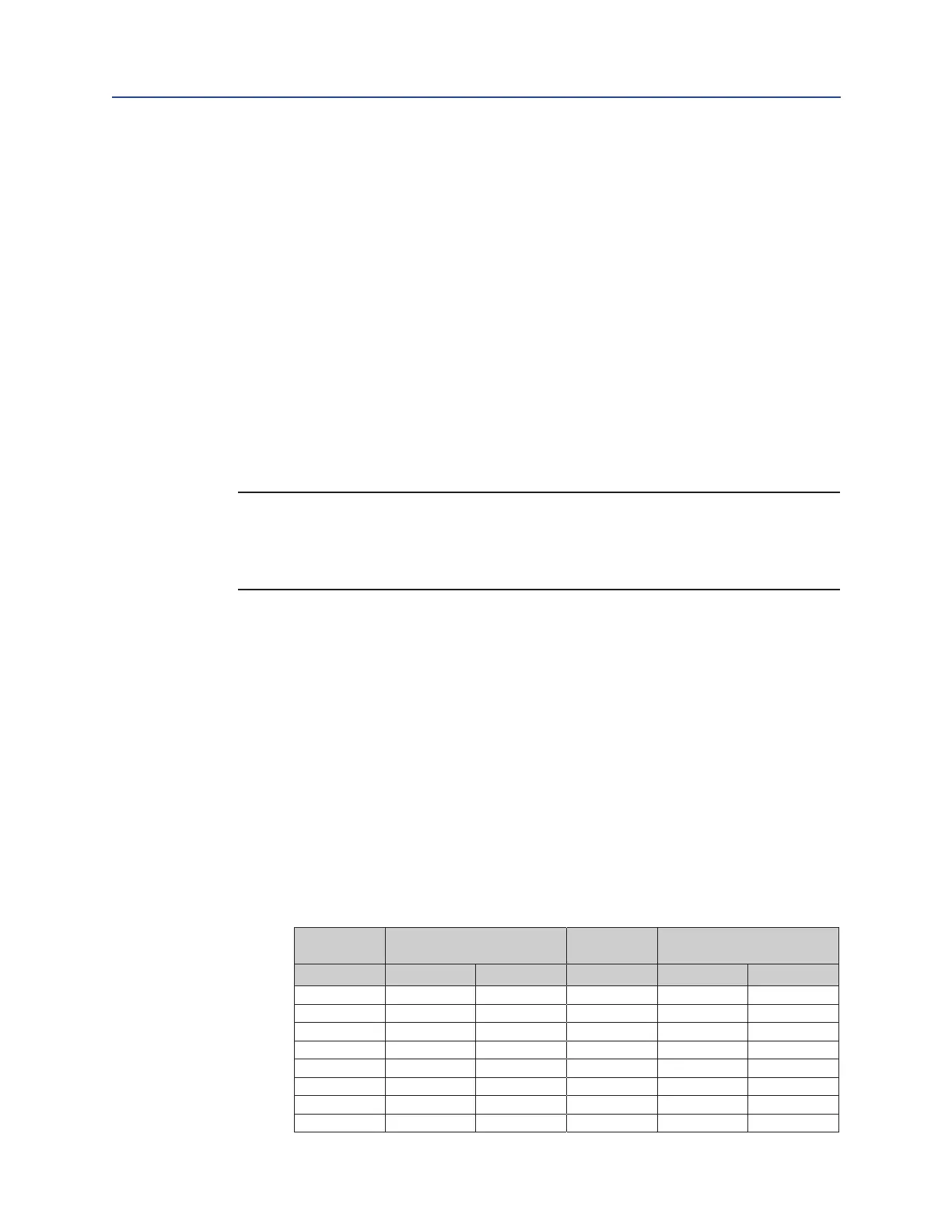

Table 2� Actuator Weight

Actuator

Model

Approximate weight (1)

Actuator

Model

Approximate weight (1)

CBB LB KG CBB LB KG

315 20 9.1 520-M3HW 38 17.2

315-M3 23.2 10.5 525 44 20

315-M3HW 25 11.3 525-M3 50 22.7

420 22 10 525-M3HW 56 25.4

420-M3 29.4 13.4 725 68 31

420-M3HW 33 15 725-M3 75 34

520 28 12.7 725-M3HW 81 37

520-M3 34.4 15.7

(1) Weight is for bare actuator without accessories or valve adaptation.

Loading...

Loading...